Magnet generator, and solid particle adsorption device and air sterilization machine manufactured through same

An adsorption device, solid particle technology, applied in chemical instruments and methods, disinfection, electrode structure, etc., can solve the problems of filter mesh filter technology mesh limit capacity filter technology mesh layer superposition, secondary diffusion, inability to accumulate purification, etc. The effect of strong market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

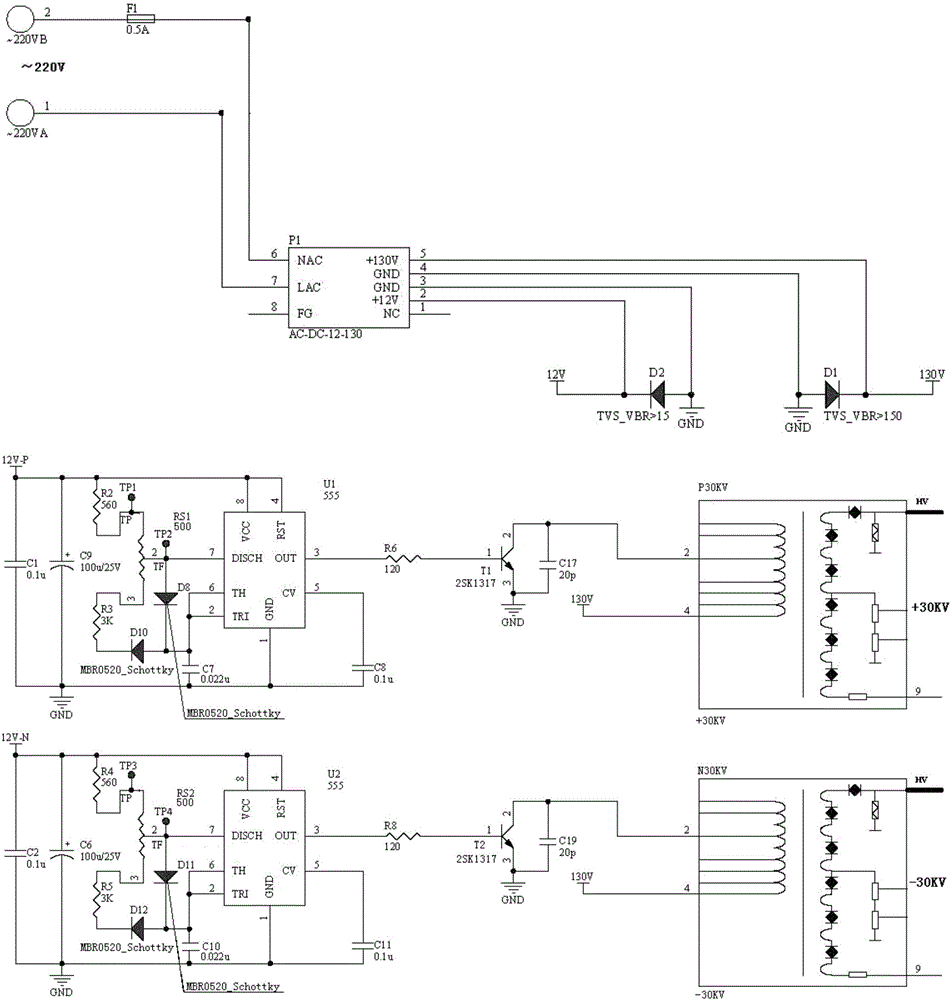

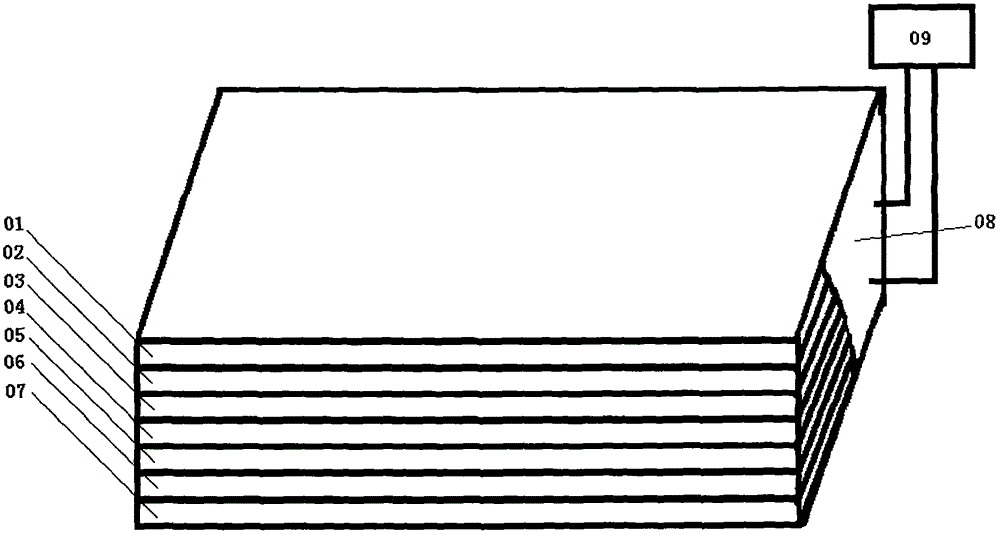

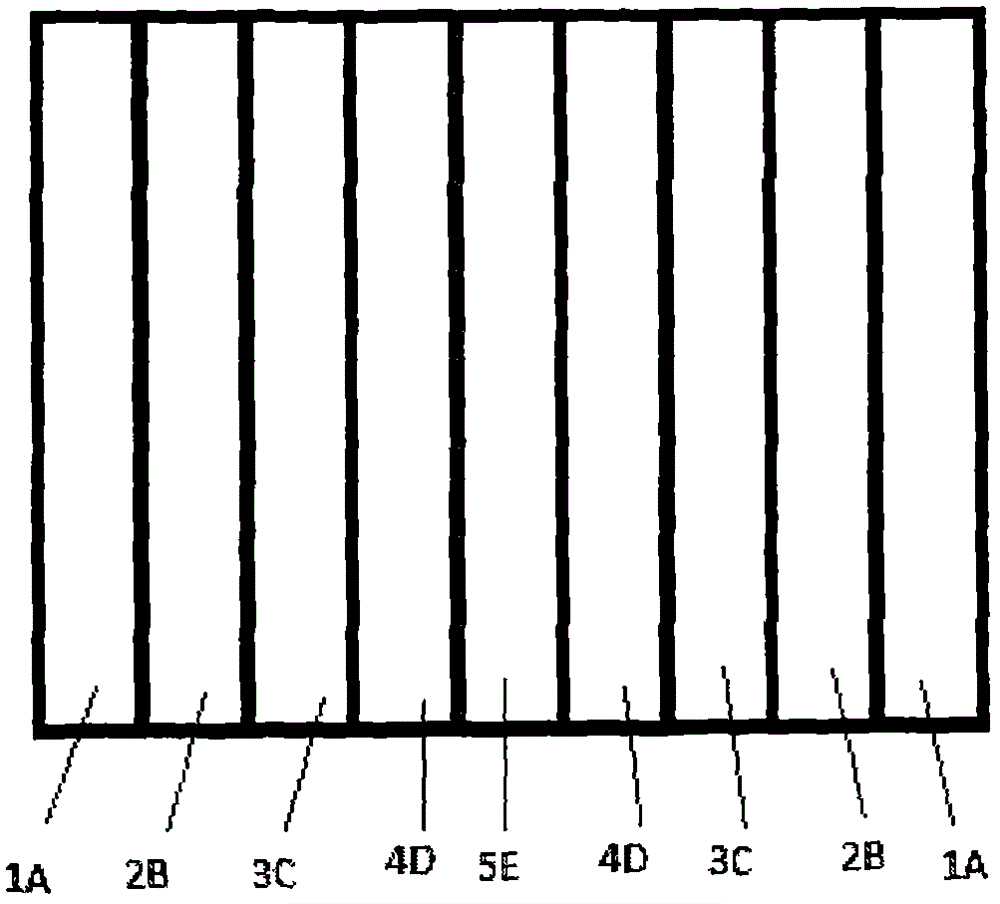

[0077] Magnet generator, the magnet generator includes 7 layers, the first layer 01 is the first silica-tempered glass (SiO 2 -Toughened glass) layer to prevent ions from escaping and serve as the overall support layer; the second layer 02 is the first titanium coating, that is, barium titanate (BaTiO 3 ) coated on SiO 2 - On the inner surface of the tempered glass, a layer of coating is formed; the third layer 03 is an aluminum wire cluster layer, and the outer two layers of the aluminum wire cluster layer are respectively aluminum wire frame layers; the two layers of aluminum wire frame layers There are two symmetrical layers of aluminum foil inside; the aluminum foil layers are respectively attached to the aluminum wire frame, and pressed to form an uneven frame shape; the middle of the two symmetrical aluminum foil layers is an aluminum wire layer; the aluminum wire layer, the aluminum wire Fibrous, divided into 5 layers, the symmetrical outer two layers are 0.1mm fiber a...

Embodiment 2

[0089] Magnet generator, the magnet generator includes 7 layers, the first layer 01 is the first silica-tempered glass (SiO 2 -Toughened glass) layer to prevent ions from escaping and serve as the overall support layer; the second layer 02 is the first titanium coating, that is, barium titanate (BaTiO 3 ) coated on SiO 2 - On the inner surface of tempered glass, a layer of coating is formed; coating barium titanate on SiO2-tempered glass has the best effect, but, limited by the technical capacity of the current process, the process cost is too high. In order to reduce the difficulty of process technology and reduce the cost of production price, the present invention coats barium titanate on SiO 2 - On tempered glass, a layer of coating is formed, here is a cheap process, which is also feasible: mix barium titanate and binder together and coat it on SiO 2 -Tempered glass on. That is, the method of barium titanate + binder is used to coat barium titanate on SiO 2- On the tem...

Embodiment 3

[0099] Magnet generator, the magnet generator includes 7 layers, the first layer 01 is the first silica-tempered glass (SiO 2 -Toughened glass) layer to prevent ions from escaping and serve as the overall support layer; the second layer 02 is the first titanium coating, that is, barium titanate (BaTiO 3 ) coated on SiO 2 - On the inner surface of the tempered glass, a layer of coating is formed; the third layer 03 is an aluminum wire cluster layer, and the outer two layers of the aluminum wire cluster layer are respectively aluminum wire frame layers; the two layers of aluminum wire frame layers There are two symmetrical layers of aluminum foil inside; the aluminum foil layers are respectively attached to the aluminum wire frame, and pressed to form an uneven frame shape; the middle of the two symmetrical aluminum foil layers is an aluminum wire layer; the aluminum wire layer, the aluminum wire Fibrous, divided into 5 layers, the symmetrical outer two layers are 0.1mm fiber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com