Nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device and method

A waste heat recovery device and a technology for methane water vapor, which are applied in the fields of environmental protection, energy saving, and metallurgical engineering, can solve the problems of low recovery utilization rate of waste heat resources and inability to meet the requirements of molten nickel-iron alloy, so as to improve recovery efficiency and utilization rate and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

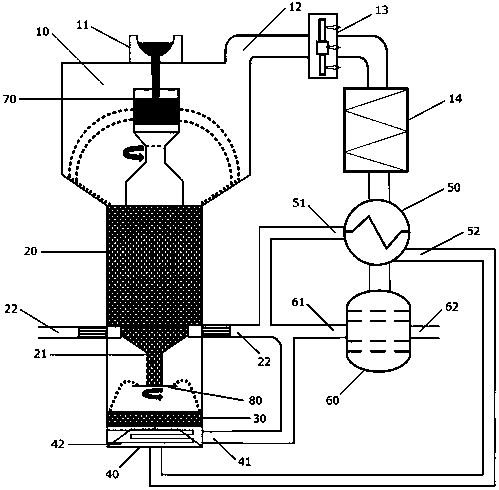

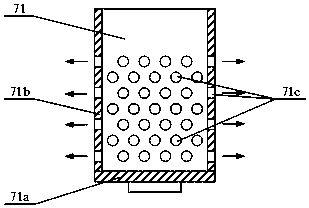

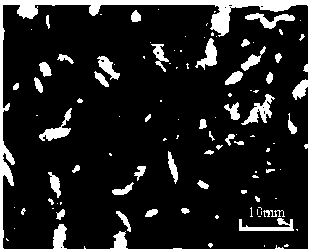

[0047]The nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device of the present invention is used to perform granulation and waste heat recovery operations on the molten nickel-iron alloy, and the dry granulator adopts the centrifugal granulation device with the optimized structure proposed by the present invention. Start the operation of the nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device, and feed methane steam into the reforming reaction bed through the methane steam inlet port, and the nickel-iron alloy dry is driven by the exhaust fan on the air flow channel. The air circulation in the waste heat recovery device of French granulation and methane steam reforming; then the liquid nickel-iron alloy at about 1600°C is injected into the nickel-iron alloy liquid inlet on the top of the dry granulator, and then flows into the dry granulator for centrifugal granulation device, the centrifugal granulation de...

Embodiment 2

[0051] The nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device of the present invention is used to perform granulation and waste heat recovery operations on the molten nickel-iron alloy, and the dry granulator adopts the centrifugal granulation device with the optimized structure proposed by the present invention. Start the operation of the nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device, and feed methane steam into the reforming reaction bed through the methane steam inlet port, and the nickel-iron alloy dry is driven by the exhaust fan on the air flow channel. Airflow circulation in the waste heat recovery device for granulation and methane steam reforming; then the liquid nickel-iron alloy at about 1630°C is injected into the nickel-iron alloy liquid inlet at the top of the dry granulator, and then flows into the dry granulator for centrifugal granulation device, the centrifugal granulation device ...

Embodiment 3

[0055] The nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device of the present invention is used to perform granulation and waste heat recovery operations on the molten nickel-iron alloy, and the dry granulator adopts the centrifugal granulation device with the optimized structure proposed by the present invention. Start the operation of the nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device, and feed methane steam into the reforming reaction bed through the methane steam inlet port, and the nickel-iron alloy dry is driven by the exhaust fan on the air flow channel. The air circulation in the waste heat recovery device of granulation and methane steam reforming; then the liquid nickel-iron alloy at about 1650 ℃ is injected into the inlet of the nickel-iron alloy liquid on the top of the dry granulator, and then flows into the dry granulator for centrifugal granulation device, the centrifugal granulation d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com