Multilayer-shell wormlike mesoporous silica and preparation method thereof

A mesoporous silica and multi-layer shell technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of preparing multi-layer shell worm-like mesoporous silica materials that have not been reported, and achieve easy implementation of process operation, The effect of preventing large-scale leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

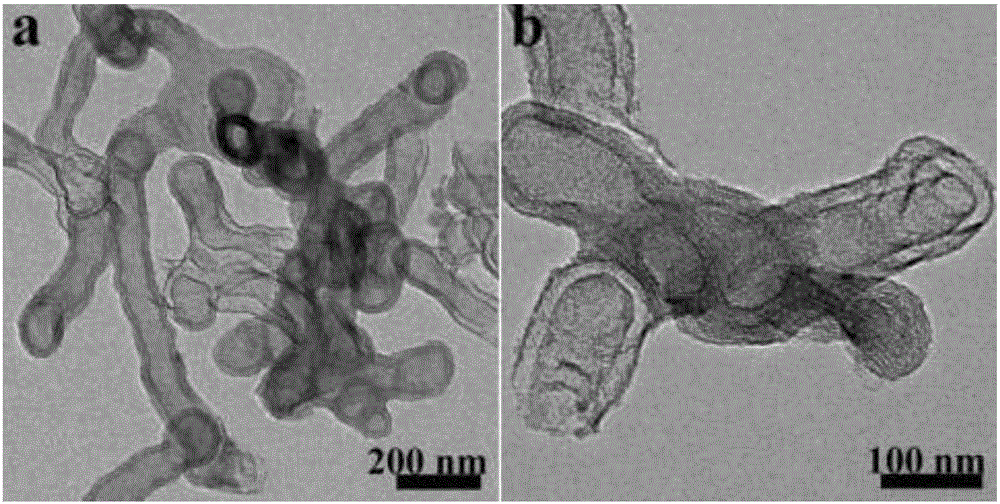

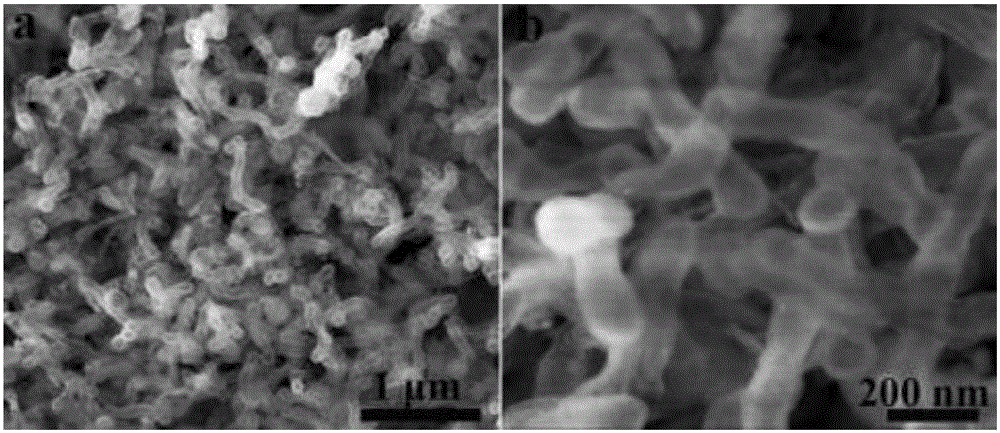

Embodiment 1

[0029] Put a 100mL beaker on a magnetic stirrer, add 35mL of distilled water and heat up to 35°C, add 0.141g of CTAB and 0.113g of DDAB to the distilled water under stirring, stir to form a transparent solution, then add 0.07g of β-CD and stir until completely dissolved , and then add 0.8mL ammonia water, after 2h, take 2g TEOS and slowly add dropwise to the solution under stirring, after sealing, keep stirring at constant temperature for 24h. The obtained white precipitate solution was transferred to a 100mL reaction kettle, and placed in a thermostat at 100°C for 24h. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 48 °C for 10 h, and then the precipitate was calcined in a tubular calciner at 500 °C for 4 h to obtain multi-layered worm-like mesoporous silica, such as figure 1 and figure 2 As shown, 3-4 layers of worm-like mesoporous silic...

Embodiment 2

[0031] Put a 100mL beaker on a magnetic stirrer, add 35mL distilled water and heat up to 35°C, add 0.141g CTAB and 0.113g DDAB to the distilled water successively under stirring, stir to form a transparent solution, add 0.1gβ-CD, stir until completely Dissolve, then add 0.8mL of ammonia water, after 2h, take 2g of TEOS and slowly drop into the solution under stirring, seal and stir at constant temperature for 24h. The obtained white precipitate solution was transferred to a 100mL reaction kettle, and placed in a thermostat at 100°C for 24h. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 48° C. for 10 h, and then the precipitate was calcined in a tubular calciner at 500° C. for 4 h to obtain a multi-layered worm-like mesoporous silica whose morphology was similar to that of Example 1.

Embodiment 3

[0033] Put a 100mL beaker on a magnetic stirrer, add 35mL distilled water and heat up to 35°C, add 0.141g CTAB and 0.113g DDAB to the distilled water successively under stirring, stir to form a transparent solution, add 0.13gβ-CD, stir until completely Dissolve, then add 0.8mL of ammonia water, after 2h, take 2g of TEOS and slowly drop into the solution under stirring, seal and stir at constant temperature for 24h. The obtained white precipitate solution was transferred to a 100mL reaction kettle, and placed in a thermostat at 100°C for 24h. After cooling, the white precipitate solution was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 48° C. for 10 h, and then the precipitate was calcined in a tubular calciner at 500° C. for 4 h to obtain a multi-layered worm-like mesoporous silica whose morphology was similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com