Method and system for preparing benzene by waste pyrolysis

A garbage and pyrolysis technology, which is applied in the field of waste resource treatment, can solve the problems that cannot meet the requirements of waste reduction, harmlessness and resource utilization, and achieve investment and operation cost savings, quality improvement, and energy conservation. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a system for producing benzene by pyrolyzing garbage.

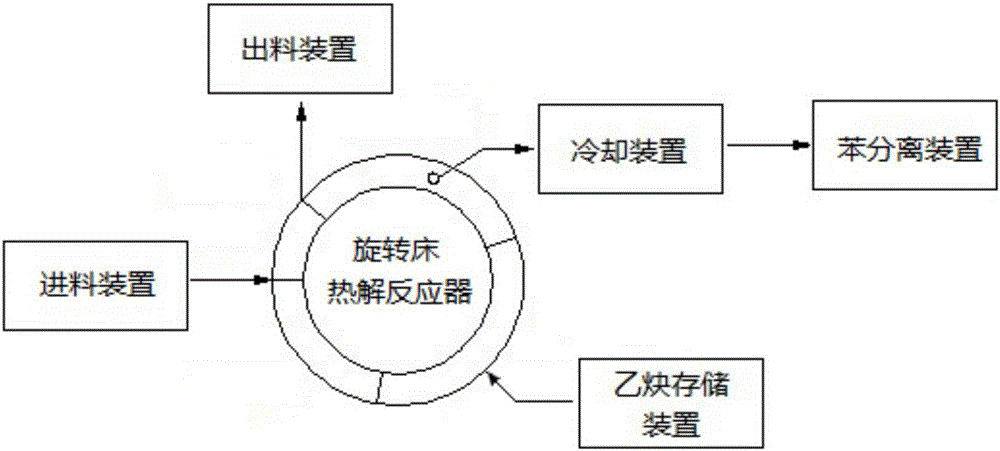

[0059] Such as figure 1 As shown, the system includes a feed device, a rotating bed pyrolysis reactor, a discharge device, an acetylene storage device, a cooling device and a benzene separation device.

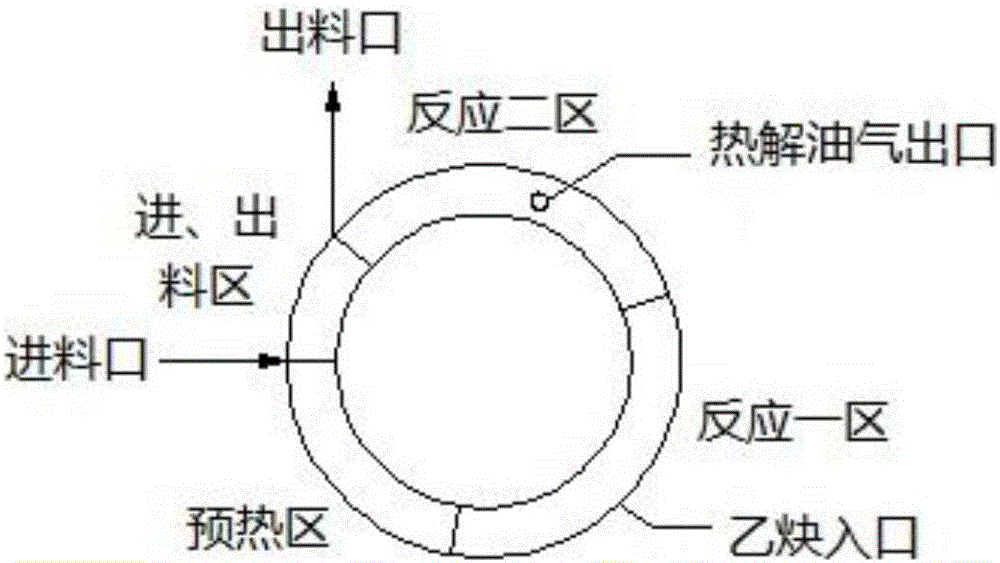

[0060] Such as figure 2 As shown, the shape of the rotating bed pyrolysis reactor is circular, which includes a feed zone, a preheating zone, a reaction zone and a discharge zone. Among them, the feed area is provided with a feed port, the reaction area is provided with an acetylene inlet and a pyrolysis oil gas outlet, and the discharge area is provided with a discharge port.

[0061] The acetylene inlet is arranged on the bottom surface of the reaction zone. The pyrolysis oil gas outlet is arranged on the side wall of the reaction zone, and is located below the heating device in the reaction zone. The heating device in the preheating zone and the reaction zone is a regenerative radia...

Embodiment 2

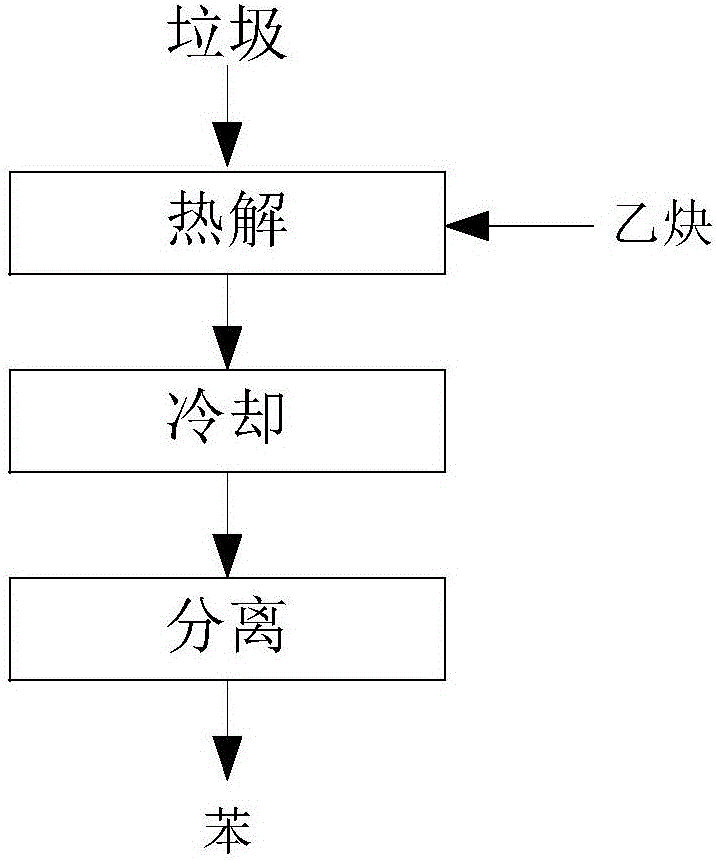

[0068] This embodiment provides a method for producing benzene by pyrolyzing garbage using the system provided in Embodiment 1. The composition of the rubbish used is shown in Table 1, and the method is as follows: image 3 As shown, the details are as follows:

[0069] Most of the garbage is pyrolyzable organic matter after being sorted, crushed, dried, and shaped. Select 1 ton of garbage with a particle size of 10-30mm and a moisture content of 13wt%, and control the temperature in the second zone of the reaction to 650°C. The compressed waste enters the rotary bed pyrolysis reactor through the feeding device, and is evenly distributed on the bottom surface of the rotary bed reactor. With the rotation of the bottom surface, it is heated to 650°C in the preheating zone, reaction zone 1 and reaction zone 2 for pyrolysis. The reaction generates pyrolysis oil gas (including non-condensable gas and pyrolysis oil) and pyrolysis charcoal. In the case of not feeding acetylene gas...

Embodiment 3

[0073] This embodiment provides another method for producing benzene by pyrolyzing garbage using the system provided in Embodiment 1. The composition of the rubbish used is the same as the rubbish used in embodiment 2, and the method is as follows image 3 As shown, the details are as follows:

[0074] Most of the garbage is pyrolyzable organic matter after being sorted, crushed, dried, and shaped. Select 1 ton of garbage with a particle size of 10-30mm and a moisture content of 5wt%, and control the temperature in the second reaction zone to 750°C. The compressed waste enters the rotary bed pyrolysis reactor through the feeding device, and is evenly distributed on the bottom surface of the rotary bed reactor. With the rotation of the bottom surface, it is heated to 750°C for pyrolysis through the preheating zone, the first reaction zone and the second reaction zone. The reaction generates pyrolysis oil gas (including non-condensable gas and pyrolysis oil) and pyrolysis char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com