Bismaleamic acid-based calcium-zinc composite heat stabilizer, preparation method and application

A technology of maleamic acid-based calcium-zinc and composite thermal stabilizers, which is applied in the direction of calcium organic compounds, zinc organic compounds, and 2/12 group organic compounds without C-metal bonds, etc., which can solve the problem of insufficient stability and thermal stability The agent contains heavy metals, the process is complicated, etc., and achieves good anti-initial coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

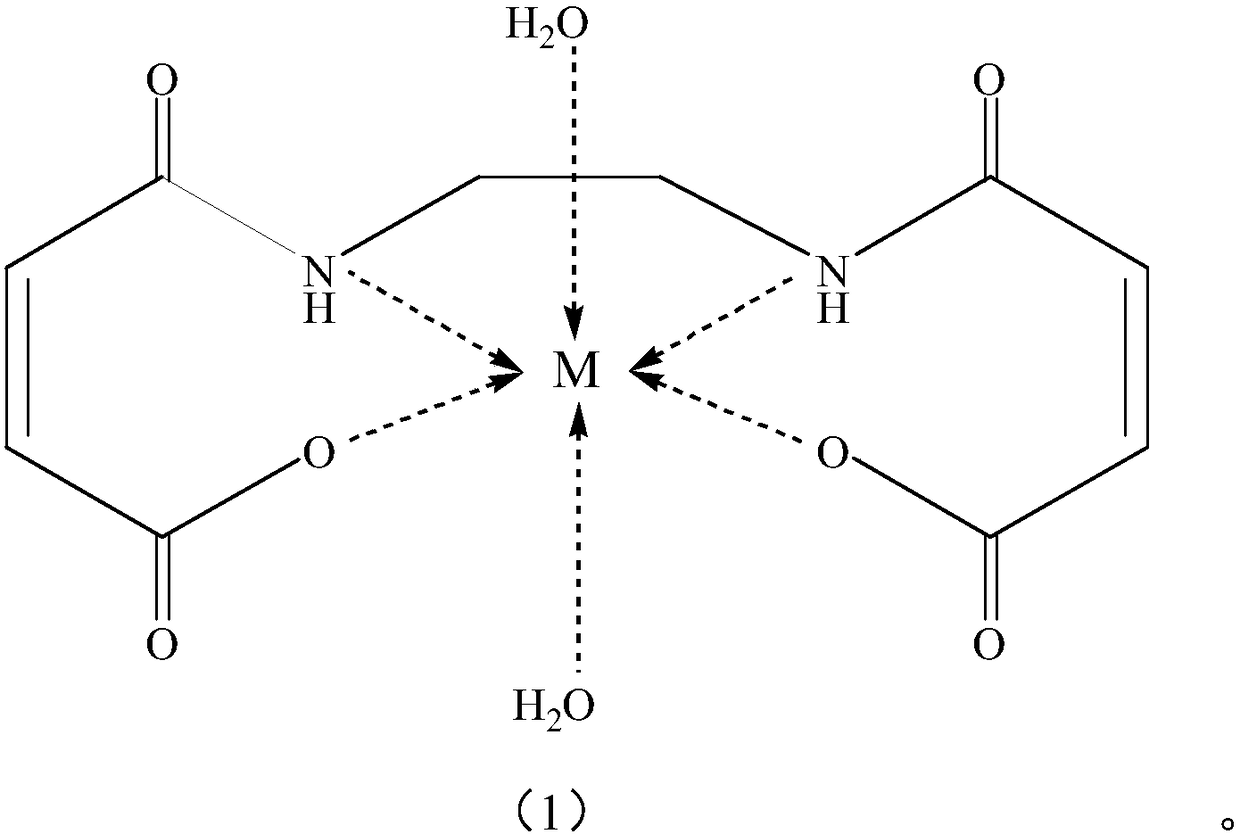

Method used

Image

Examples

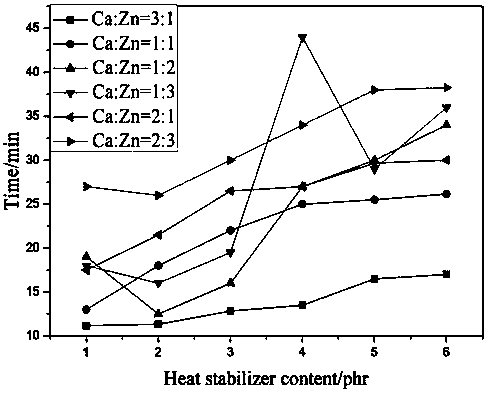

Embodiment 1

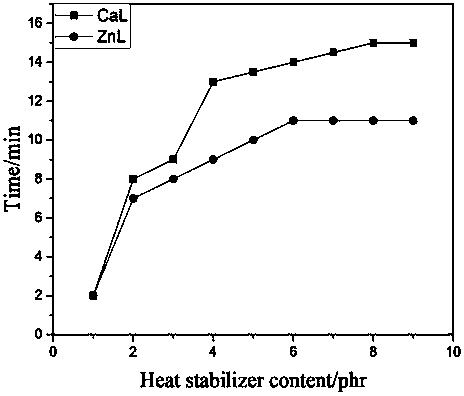

[0027] Using maleic anhydride as a raw material, maleic anhydride and ethylenediamine were dissolved in acetonitrile at a ratio of 2:1, and the acetonitrile solution of maleic anhydride was added dropwise to acetonitrile under ice-water bath conditions. In the acetonitrile solution of diamine, fully stirred and reacted for 3 hours, then filtered with suction, washed with absolute ethanol three times, and dried under vacuum at 40°C. Get ethylenediamine bismaleamic acid;

[0028] Reaction of ethylenediamine bismaleamic acid with sodium hydroxide of 2 times the amount of the substance in methanol solution to obtain a methanol solution of ethylenediamine bismaleamic acid sodium, adjust the pH value to 7-8, and then add to it Add calcium chloride methanol solution drop by drop, stir and reflux reaction at 100°C to obtain white precipitate, wash and dry the product to constant weight to obtain calcium ethylenediamine bismaleamate;

[0029] Reaction of ethylenediamine bismaleamic ac...

Embodiment 2

[0032] The specific preparation method is the same as that of Example 1, except that calcium ethylenediamine bismaleamate and zinc ethylenediamine bismaleamate are compounded according to a mass ratio of 1:2.

Embodiment 3

[0034] The specific preparation method is the same as that of Example 1, except that calcium ethylenediamine bismaleamate and zinc ethylenediamine bismaleamate are compounded at a mass ratio of 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com