High-toughness bionic bait and preparation method thereof

A technology of bionic bait and high toughness, applied in artificial fish bait, fishing, animal husbandry, etc., can solve the problems of environmental pollution, bionic bait cannot be degraded, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

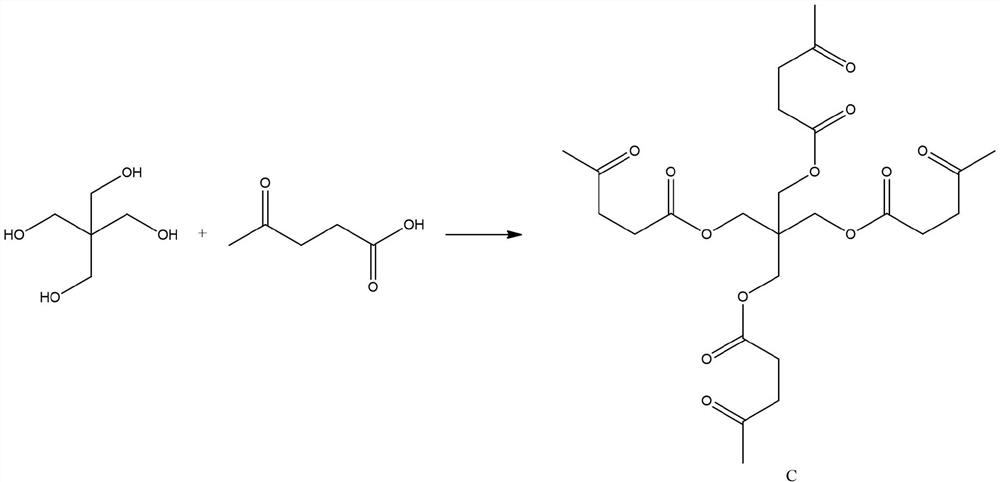

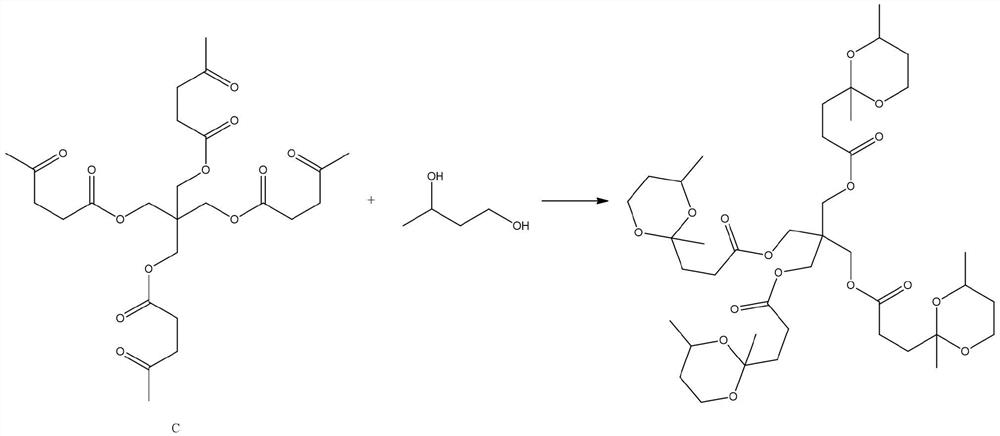

Method used

Image

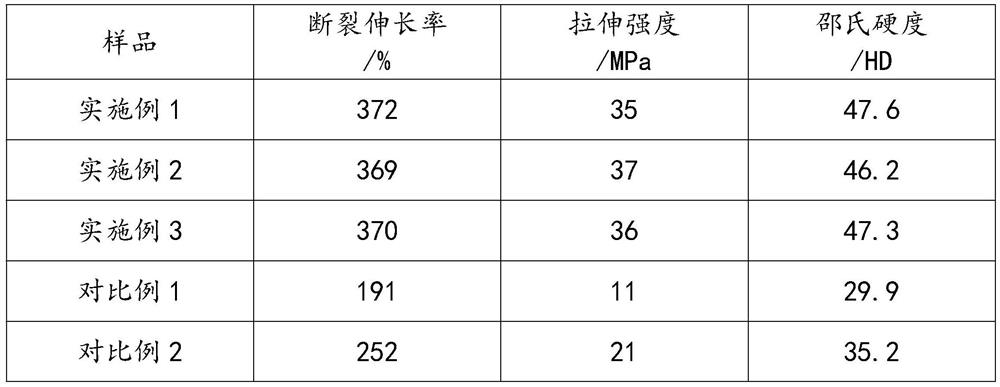

Examples

Embodiment 1

[0039] This embodiment is a bionic bait with high toughness, comprising the following steps:

[0040] S1: Mix the modified polycaprolactone, modified toughening agent, food attractant, pigment, antioxidant, calcium zinc stabilizer, and lubricant in a high-speed mixer to obtain a blend;

[0041] S2: adding the obtained blend into the hopper of a twin-screw extruder, performing melt extrusion, drawing, cooling, pelletizing and drying to obtain blend granules;

[0042] S3: Add the blended material particles into the injection molding machine for injection molding to obtain the desired shape of high-toughness bionic fishing bait;

[0043] Wherein the preparation process of modified polycaprolactone is as follows:

[0044] S31: Add sodium lignosulfonate and distilled water into the conical flask, heat and stir to 35°C, add citraconic anhydride and adjust the pH to 10 with sodium hydroxide solution, control the temperature at 30°C, react for 4 hours, add dilute sulfuric acid soluti...

Embodiment 2

[0050] This embodiment is a bionic bait with high toughness, comprising the following steps:

[0051] S1: Mix the modified polycaprolactone, modified toughening agent, food attractant, pigment, antioxidant, calcium zinc stabilizer, and lubricant in a high-speed mixer to obtain a blend;

[0052] S2: adding the obtained blend into the hopper of a twin-screw extruder, performing melt extrusion, drawing, cooling, pelletizing and drying to obtain blend granules;

[0053] S3: Add the blended material particles into the injection molding machine for injection molding to obtain the desired shape of high-toughness bionic fishing bait;

[0054] Wherein the preparation process of modified polycaprolactone is as follows:

[0055] S31: Add sodium lignosulfonate and distilled water into the Erlenmeyer flask, heat and stir to 45°C, add citraconic anhydride and adjust the pH to 11 with sodium hydroxide solution, control the temperature at 40°C, react for 5 hours, add dilute sulfuric acid sol...

Embodiment 3

[0061] This embodiment is a bionic bait with high toughness, comprising the following steps:

[0062] S1: Mix the modified polycaprolactone, modified toughening agent, food attractant, pigment, antioxidant, calcium zinc stabilizer, and lubricant in a high-speed mixer to obtain a blend;

[0063] S2: adding the obtained blend into the hopper of a twin-screw extruder, performing melt extrusion, drawing, cooling, pelletizing and drying to obtain blend granules;

[0064] S3: Add the blended material particles into the injection molding machine for injection molding to obtain the desired shape of high-toughness bionic fishing bait;

[0065] Wherein the preparation process of modified polycaprolactone is as follows:

[0066] S31: Add sodium lignosulfonate and distilled water into the conical flask, heat and stir to 45°C, add citraconic anhydride and adjust the pH to 10 with sodium hydroxide solution, control the temperature at 40°C, react for 4 hours, add dilute sulfuric acid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com