A production process of silver and cadmium oxide with coarse and fine particles combined with internal oxidation method

A production process, a technology of silver cadmium oxide, applied in the field of coarse and fine particles with internal oxidation method of silver cadmium oxide production process, can solve the problems of low elongation, material transfer resistance is not as good as coarse particle oxide, high material resistivity, and achieve performance The effect of improving the comprehensive application level of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

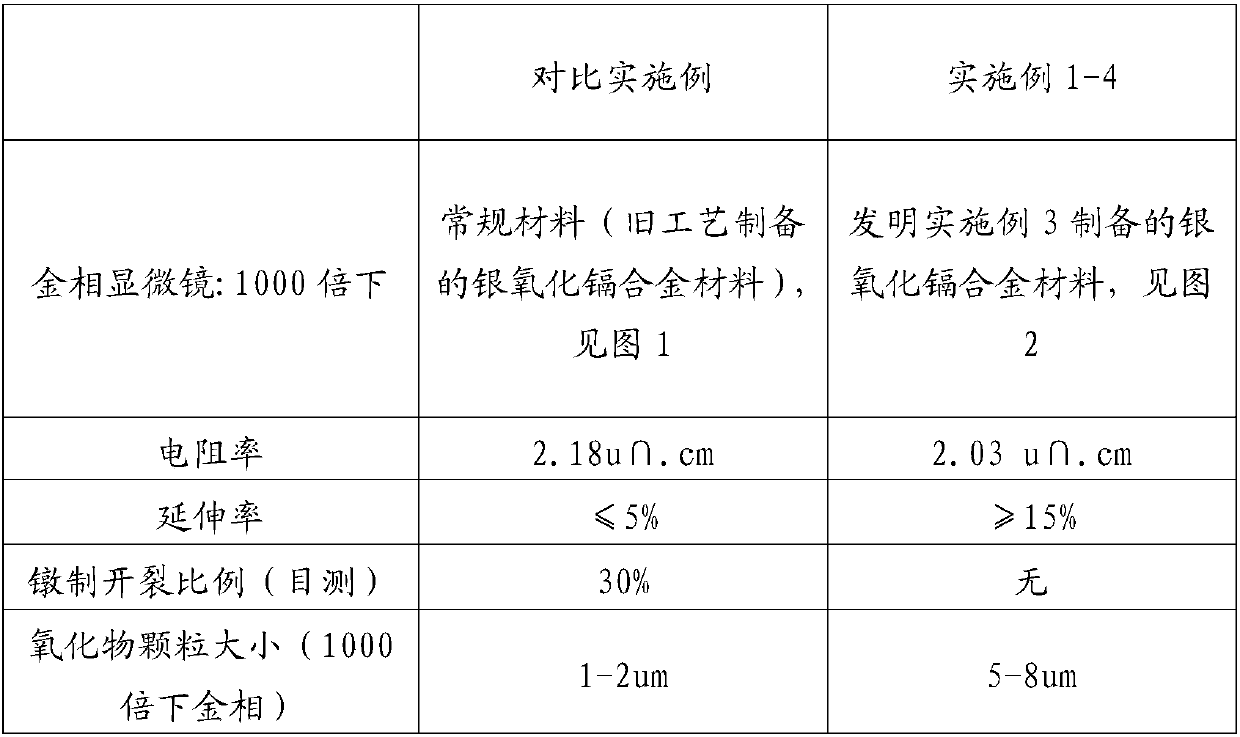

Image

Examples

Embodiment 1

[0031] A method for making a silver-cadmium oxide alloy material, comprising the steps of:

[0032] (1) Place the silver cadmium oxide composition in an intermediate frequency induction melting furnace in proportion to smelt and cast ingots; the mass fraction percentages of each element in the silver cadmium oxide composition are: silver 90.295%, cadmium 8%, indium 1%, tin 0.005%, Antimony 0.1%, Tellurium 0.1%, Nickel 0.4%, Copper 0.1%;

[0033] (2) After the surface of the cast ingot is turned and cleaned, it is heated to 750 degrees Celsius and extruded into a silver-cadmium alloy wire rod, drawn to 2.0mm, and cut into 1-5cm line segments;

[0034] (3) Put the wire rod into the internal oxidation furnace for oxidation, oxygen pressure: 0.3mpa, heat preservation at 700 degrees Celsius for 5 hours, high temperature section: heat preservation at 880 degrees Celsius for 18 hours;

[0035] (4) After the wire rod is oxidized out of the furnace, it is cleaned and polished, and aft...

Embodiment 2

[0038] A method for making a silver-cadmium oxide alloy material, comprising the steps of:

[0039] (1) Place the silver cadmium oxide composition in an intermediate frequency induction melting furnace in proportion to smelt and cast ingots; the mass fraction percentages of each element in the silver cadmium oxide composition are: silver 88.295%, cadmium 8%, indium 3%, tin 0.005%, Antimony 0.1%, tellurium 0.1%, nickel 0.2%, copper 0.3%.

[0040] (2) After the surface of the cast ingot is turned and cleaned, it is heated to 750 degrees Celsius and extruded into a silver-cadmium alloy wire rod, drawn to 2.0mm, and cut into 1-5cm line segments;

[0041] (3) Put the wire rod into the internal oxidation furnace for oxidation, oxygen pressure: 0.5mpa, heat preservation at 650 degrees Celsius for 3 hours, high temperature section: heat preservation at 800 degrees Celsius for 22 hours;

[0042] (4) After the wire rod is oxidized out of the furnace, it is cleaned and polished, and aft...

Embodiment 3

[0045] A method for making a silver-cadmium oxide alloy material, comprising the steps of:

[0046] (1) Place the silver cadmium oxide composition in an intermediate frequency induction melting furnace in proportion to smelt and cast ingots; the mass fraction percentages of each element in the silver cadmium oxide composition are: silver 85.295%, cadmium 13.9%, indium 0.1%, tin 0.005%, Antimony 0.1%, tellurium 0.1%, nickel 0.4%, copper 0.1%.

[0047] (2) After the surface of the cast ingot is turned and cleaned, it is heated to 750 degrees Celsius and extruded into a silver-cadmium alloy wire rod, drawn to 2.0mm, and cut into 1-5cm line segments;

[0048] (3) Put the wire rod into the internal oxidation furnace for oxidation, oxygen pressure: 0.3mpa, heat preservation at 600 degrees Celsius for 5 hours, high temperature section: heat preservation at 850 degrees Celsius for 20 hours;

[0049](4) After the wire rod is oxidized out of the furnace, it is cleaned and polished, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com