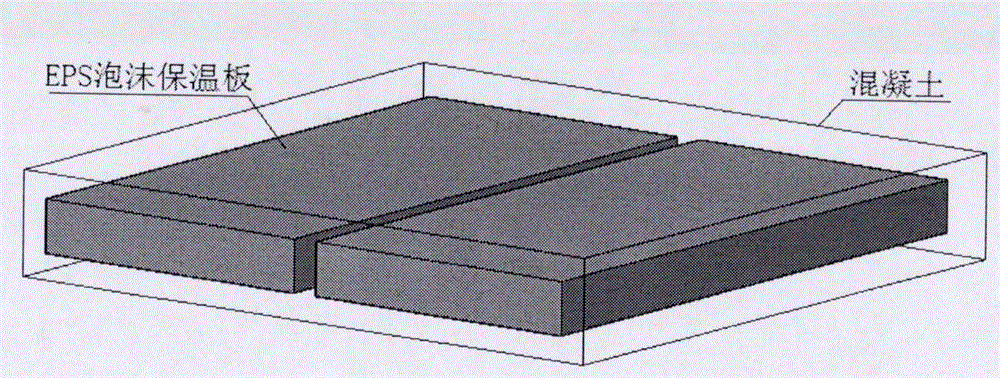

Anti-frost heaving canal lining plate containing thermal insulation material

A technology of thermal insulation material and lining, which is applied in the field of thermal insulation lining structures of water conveyance channels, can solve the problems of threatening the safety of water conveyance in channels, damage to the lining body, and difficulty in construction, and achieves the advantages of obvious thermal insulation effect, enhanced overall strength, and reduced construction difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

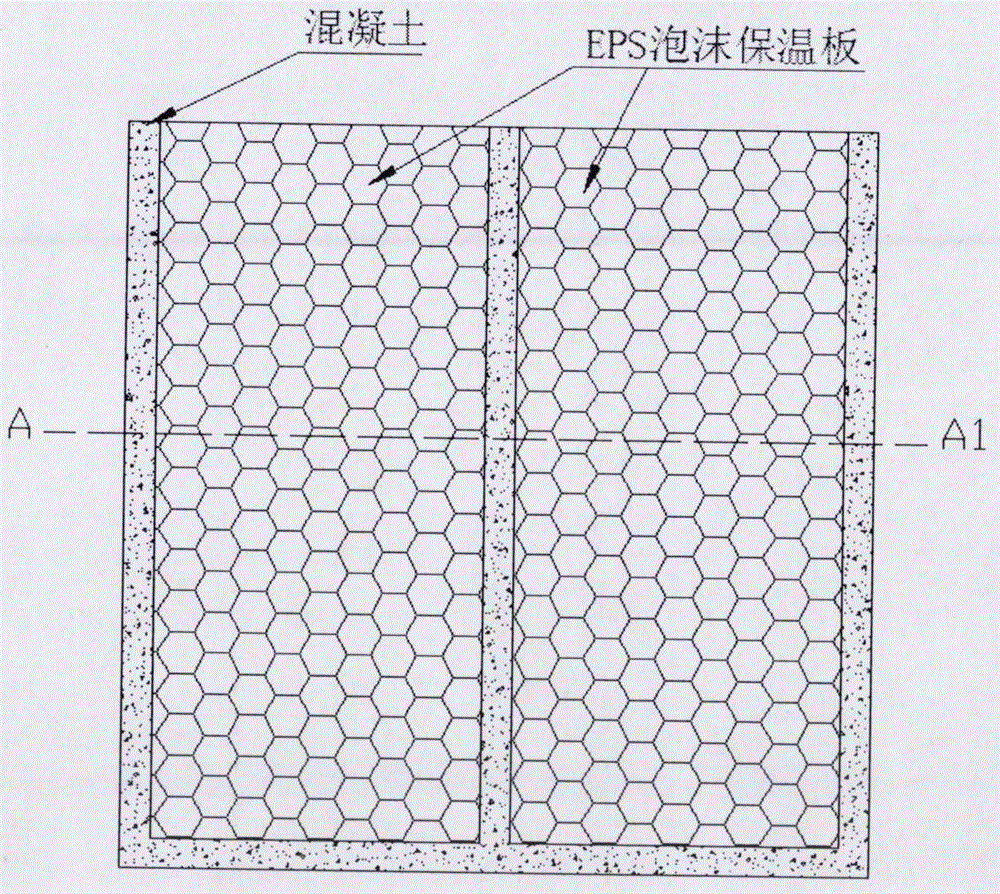

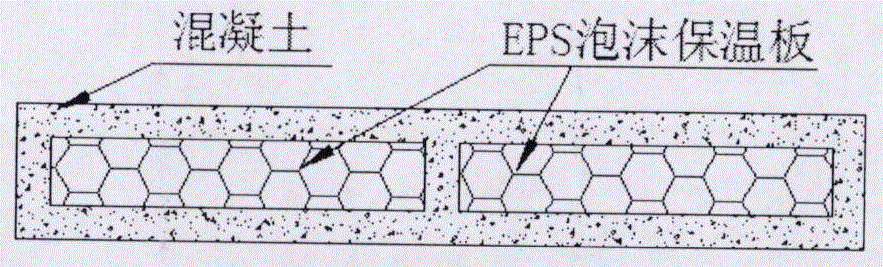

[0026] The prefabrication process of the prefabricated thermal insulation lining board of the present invention mainly includes stages such as configuration of concrete, prefabrication and maintenance of the lining body, and filling of thermal insulation materials. The specific implementation process is as follows:

[0027] Configure C15 concrete: configure cement, gravel (bean stone), sand, and water according to the ratio given in the specification to form concrete with impermeability and frost heaving grades up to the standard.

[0028] Prefabrication of the lining body: fix the inner mold and outer mold in the corresponding position, coat them with a layer of release agent, place them on a vibrating table, pour concrete into the mold, and vibrate for compaction.

[0029] Maintenance and demoulding: Carry out post-maintenance, and after the maintenance reaches the required age, demoulding (inner mold and outer mold) is carried out.

[0030] Insulation material filling: The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com