Shock-absorbing structure with transmission

A technology of belt drive and drive wheel, which is applied to the transmission device, transmission device parts, belt/chain/gear, etc., can solve the problems of high production cost, achieve low cost, solve the problem of high noise, and flexible installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

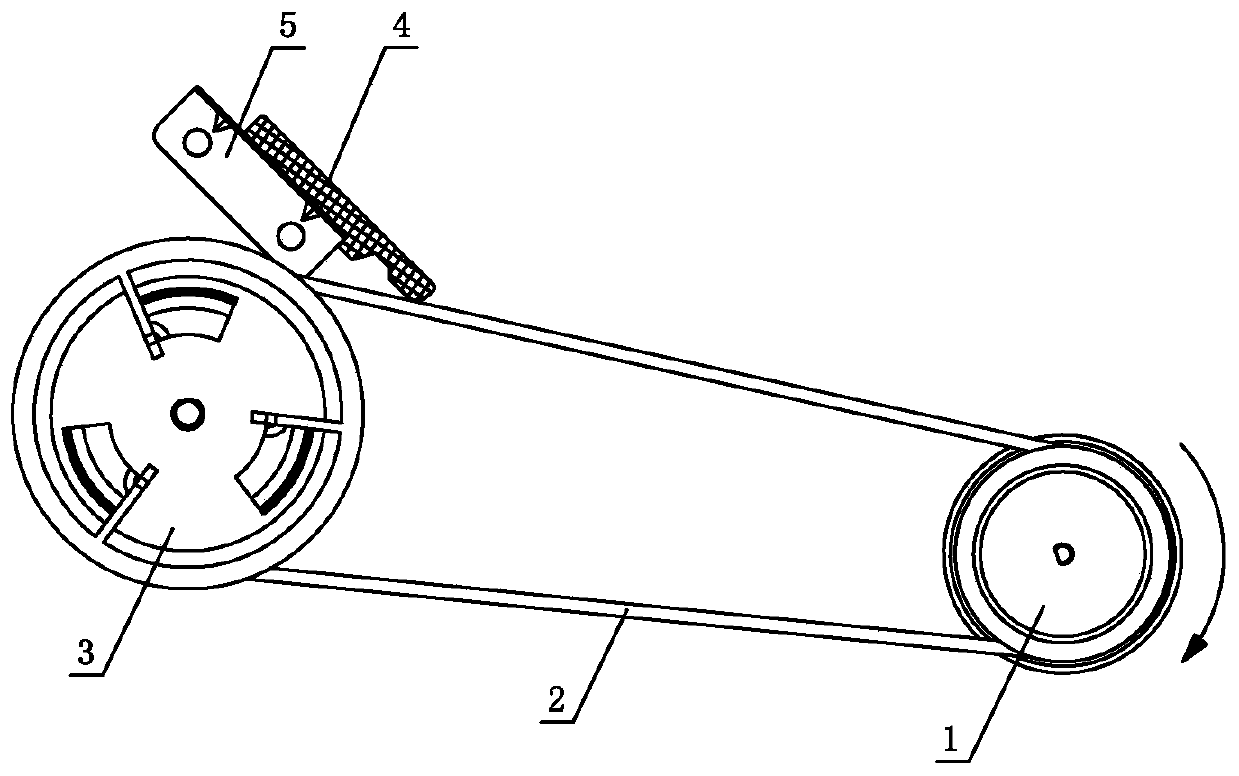

[0045] see Figure 1-Figure 4 , the damping structure with transmission is applied to the top-mounted microwave oven with hot air convection function, and is used to drive the fan blade to rotate. It includes a transmission wheel 1, a transmission belt 2 and a driving wheel 3. The driving wheel 3 is connected to the motor output shaft and passes The belt 2 drives the transmission wheel 1, and the transmission wheel 1 is connected to the fan blades; in addition, it also includes a vibration damping block 4 set corresponding to the transmission belt 2, and the vibration absorption block 4 is provided with a contact surface 4.1, and the contact surface 4.1 and the transmission belt 2 Interval fit or direct contact with each other; when the interval fit between the contact surface 4.1 and the transmission belt 2, the gap is small and cannot be too large.

[0046] Furthermore, it also includes a bracket 5 fixedly arranged on the microwave oven, and the vibration-damping block 4 is ...

no. 2 example

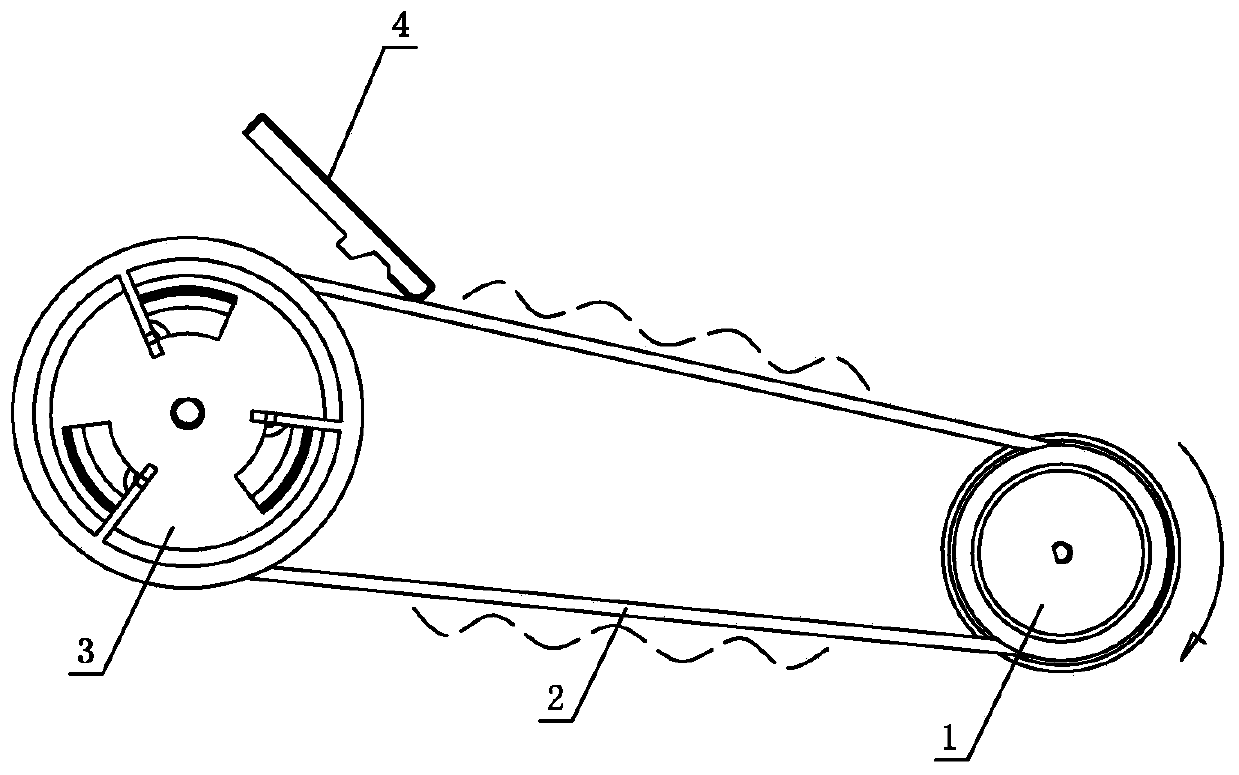

[0053] see Figure 5 The shock absorbing structure of the belt drive in this embodiment differs from the first embodiment in that: the contact surface 4.1 is a plane, and the contact surface 4.1 of the plane is parallel to the transmission belt 2 .

[0054] Other parts not described are the same as those of the first embodiment, and will not be described in detail here.

no. 3 example

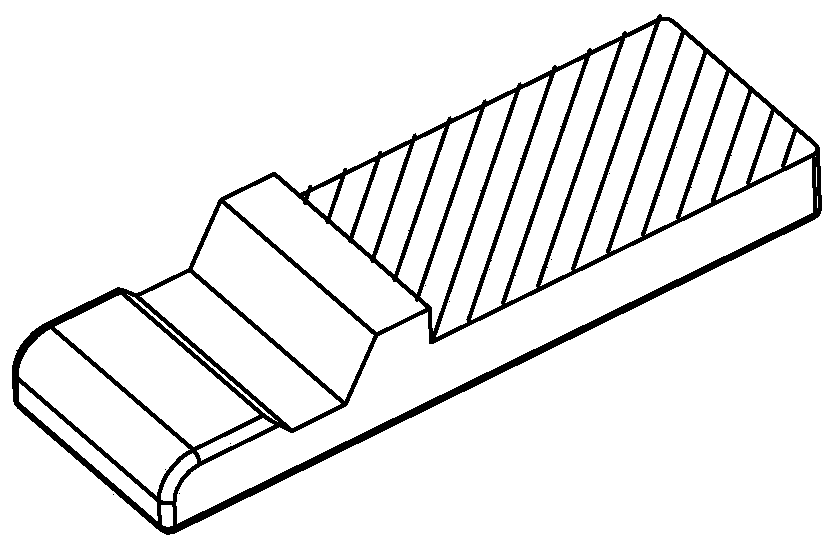

[0056] see Figure 6-Figure 8 , the damping structure with transmission of the present embodiment is different from the first embodiment in that: the damping block 4 is provided with a through hole 4.2, the bracket 5 is correspondingly provided with a screw hole 5.1, and the damping block 4 The bracket 5 is fixedly connected to each other through the screw 6; the through hole 4.2 is arranged in a circular shape, and the screw 6 passes through the through hole 4.2 and is screwed into the screw hole 5.1 to realize the fixed connection between the vibration damping block 4 and the bracket 5.

[0057] Other parts not described are the same as those of the first embodiment, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com