Monitoring system for monitoring durability deterioration evolution of reinforced concrete structure

A reinforced concrete and monitoring system technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of single monitoring parameters, immobile sensing elements, long-term battery replacement of external collectors, etc., to achieve The effect of accurate service life and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The preparation method of the chloride ion probe specifically includes:

[0076] In the first step, choose a silver rod with a purity of 99.99% and a diameter of 1 to 5 mm and a length of 20 to 30 mm, and wash it with concentrated ammonia water with a concentration of 25% to 30% for 6 hours;

[0077] In the second step, the cleaned silver rod is immersed in distilled water for another 12 hours. The two-thirds length of the silver rod should be placed in a 0.1M HCL solution with a constant current density of 0.4mA / mm 2 Polarization for 30min;

[0078] The third step is to soak the silver rod in distilled water for 24 hours, and the unpolarized area needs to be wrapped with Teflon tape for protection;

[0079] The fourth step is to draw out the copper wire at the central axis of the electrode at one end that is not polarized, and then put the electrode in the PVC tube, where the polarized part is exposed by 4-6mm;

[0080] The fifth step is to seal the PVC pipe with epoxy resin, an...

Embodiment 1

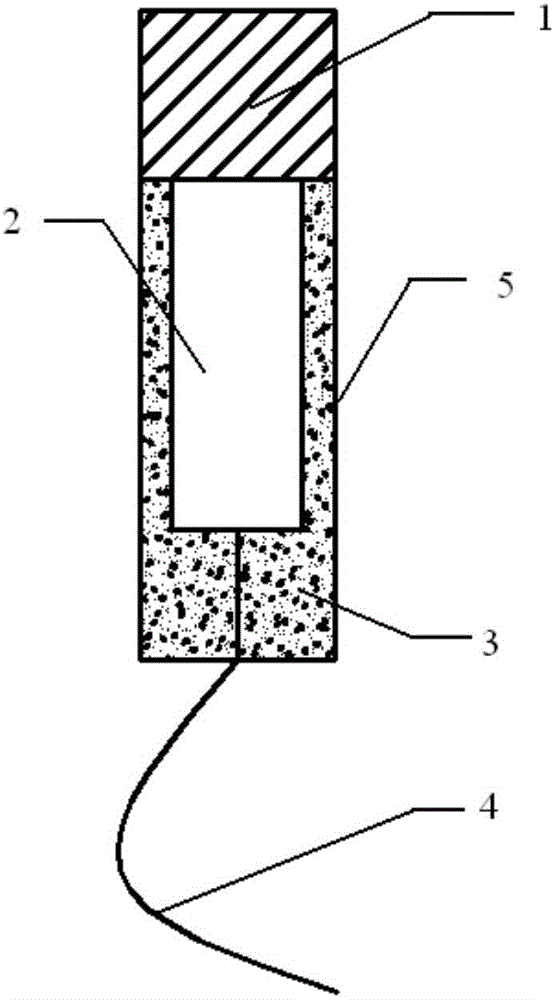

[0097] Example 1 Preparation of chloride ion probe

[0098] Such as figure 1 As shown, a silver rod with a purity of 99.99%, a diameter of 1 to 5 mm and a length of 20 to 30 mm, is selected and washed with concentrated ammonia water with a concentration of 25% to 30% for 6 hours; the washed silver rod is then immersed in distilled water 12 Hours, two-thirds of the length of the silver rod should be placed in a 0.1M HCL solution with a constant current density of 0.4mA / mm 2 Polarize for 30 minutes; then soak the silver rod in distilled water for 24 hours, and the non-polarized area needs to be wrapped with Teflon tape for protection; lead the copper wire 4 at the center axis of the electrode at the unpolarized end, and then the electrode Put it in the PVC pipe 5, where the polarized part 2 is exposed for 4-6m, the corresponding PVC pipe 5 is encapsulated with cement paste, and the resin 3 seals the part of the PVC pipe 5, and fixes the electrodes and wires by the way.

Embodiment 2

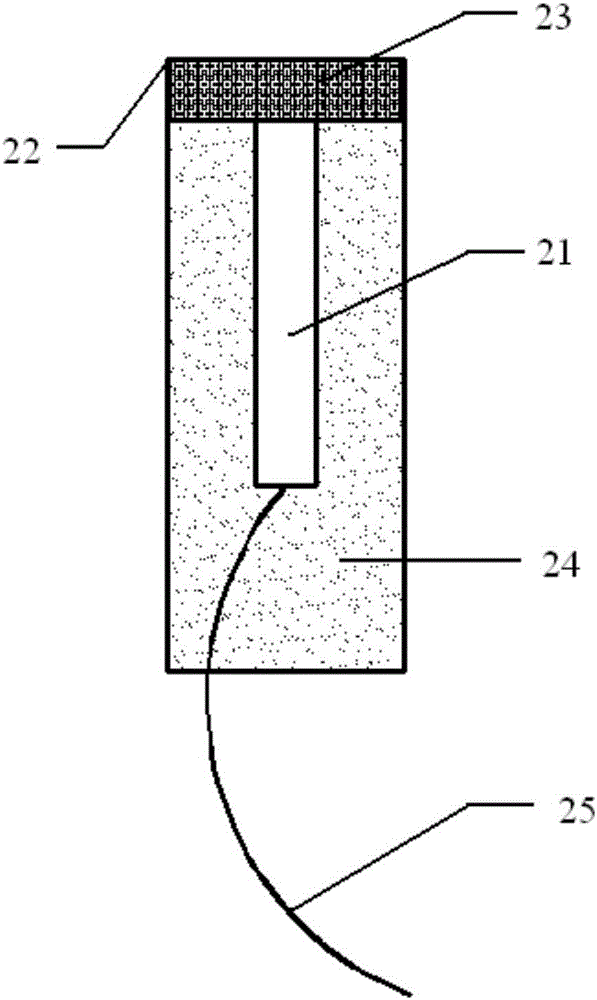

[0099] Example 2 Preparation of pH probe

[0100] Choose a metal iridium wire with a length of about 1cm, wash it with absolute ethanol and deionized water, and wipe it dry; put the iridium wire in an alumina pot containing a proper amount of carbonate, and place it in a high-temperature furnace, and control the furnace temperature to 500 ~700℃ constant temperature time 1h, high temperature environment can fully oxidize the surface of the iridium wire, forming a dense iridium oxide film with a certain thickness, forming Ir / IrO 2 Electrode; clean with deionized water, connect with copper wire by spot welding, and encapsulate with epoxy glue; newly prepared IrO 2 The electrode needs to be aged before it can be used, and the fresh IrO 2 The electrode is immersed in the concrete simulation hole solution (0.6mol / L KOH+0.2mol / L NaOH+0.001mol / LCa(OH) 2 ) Aging for 28 days.

[0101] The structure of the entire pH probe is as figure 2 As shown, the pH probe 21 is encapsulated in a PVC tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com