Prediction and control method of nickel-base super alloy microstructure on the basis of BP (Back Propagation) neural network

A nickel-based superalloy, BP neural network technology, applied in neural learning methods, biological neural network models, special data processing applications, etc., can solve problems such as difficult to control microstructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

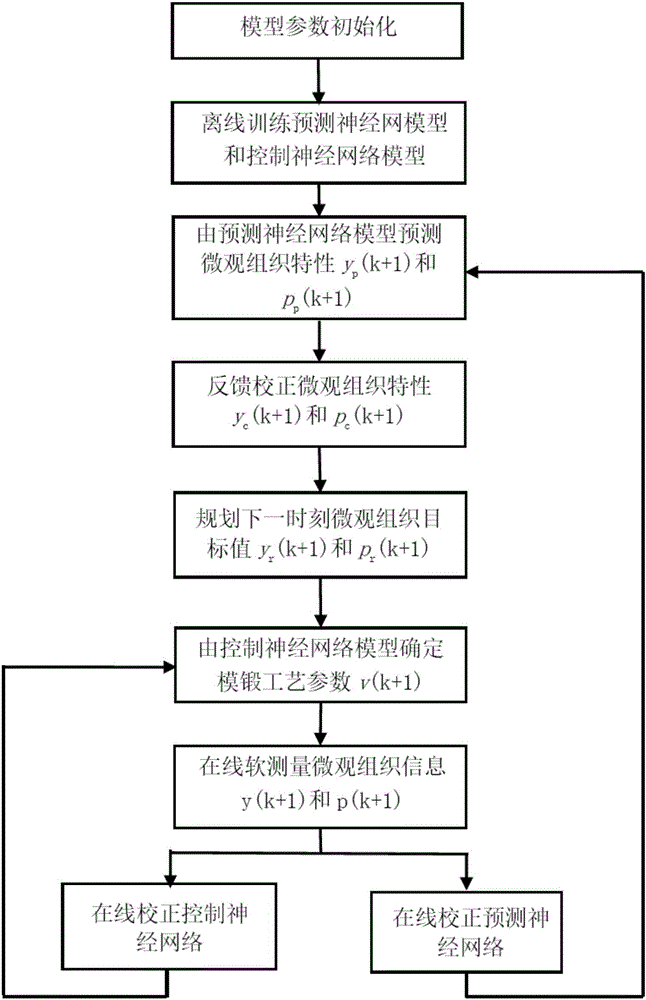

[0081] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

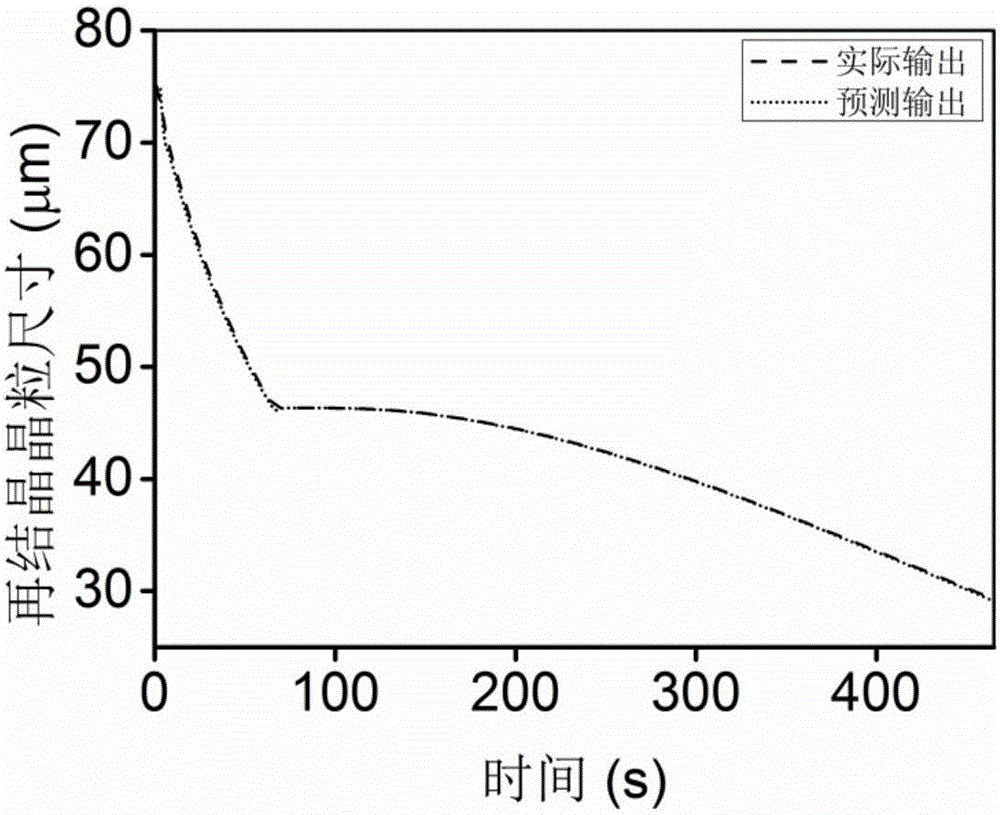

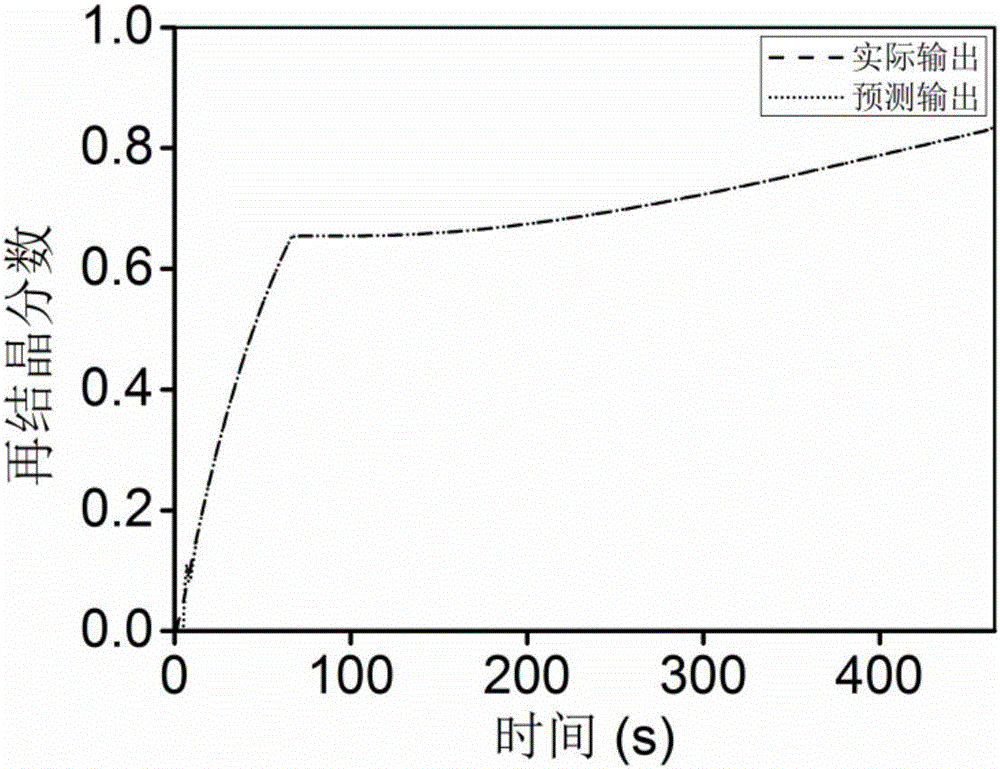

[0082] The invention is a method for predicting and controlling the microstructure of a nickel-based superalloy, the flow chart of which is as follows figure 1 shown. Below in conjunction with the finite element simulation software DEFORM-3D, introduce in detail the implementation details of the nickel-base superalloy microstructure predictive control involved in the present invention, its method comprises:

[0083] Step 1: Initialize the parameters in the training prediction neural network model and the control neural network model, and train the prediction neural network model and the control neural network model offline according to the historical die forging process parameters and microstructure information;

[0084] The initialization parameters mainly include: learning rate η = 0.01, feedback correction weight coefficient h = 1, soften...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com