Cable especially for electric welding machine

A special cable, electric welding machine technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of cracking, no protective layer against mechanical force, etc., achieve good environmental resistance, improve product quality and performance, The effect of structurally novel science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

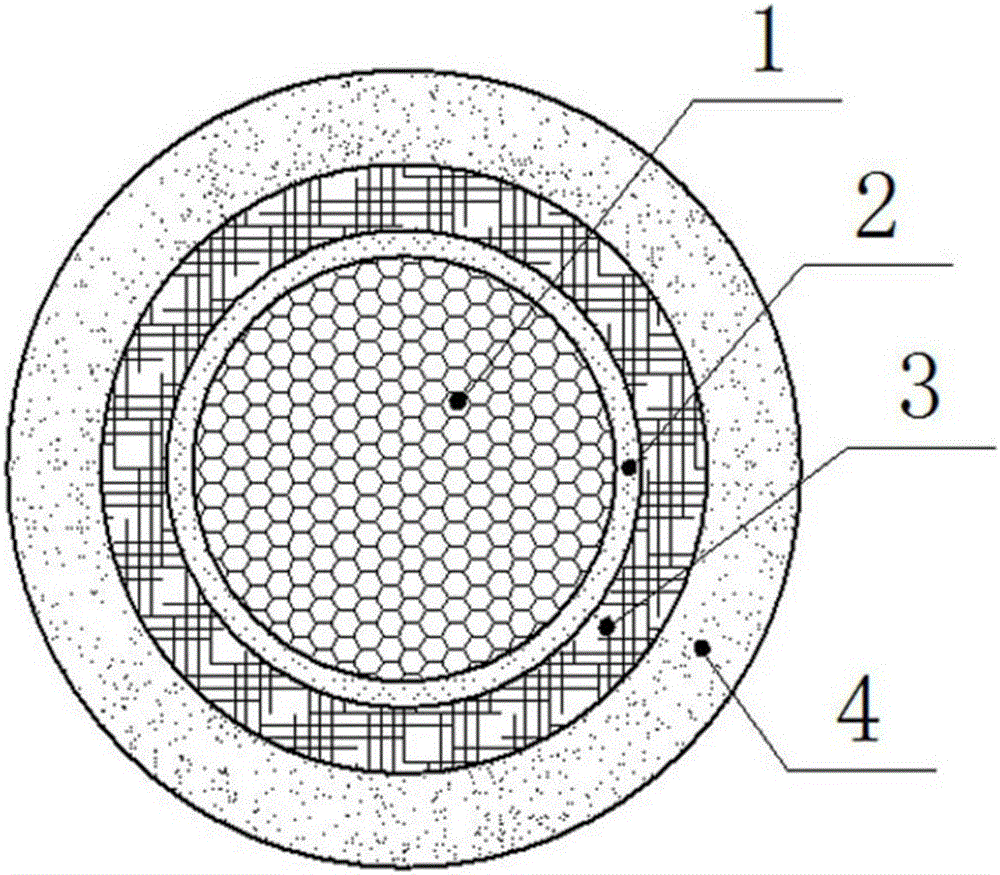

[0010] see figure 1 , a special cable for electric welding machines, which sequentially includes a conductor 1, a tape protection layer 2, a braided protection layer 3 and a TPV double sheath 4 from the inside to the outside; The protective layer 2 is made of heat-resistant polyester film insulating tape, the braided protective layer 3 is braided with high-strength aromatic fiber wire, and the TPV double sheath 4 is made of vulcanization-free thermoplastic dynamic vulcanized rubber. layers are co-extruded.

[0011] The cable of the invention has the characteristics of high twist resistance, high tensile strength, good flexibility, small vibration during operation, good directionality, small free bending diameter, continuous bending resistance and good environment resistance. It has the characteristics of small structure, light specific gravity, high anti-aging performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com