Cobalt titanium blue coated lithium titanate and preparation method thereof

A technology of green-coated lithium titanate and lithium titanate, which is applied in the field of lithium-ion secondary battery anode materials, can solve problems such as gas generation and impact on applications, and achieve the effects of preventing side reactions, inhibiting battery swelling, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

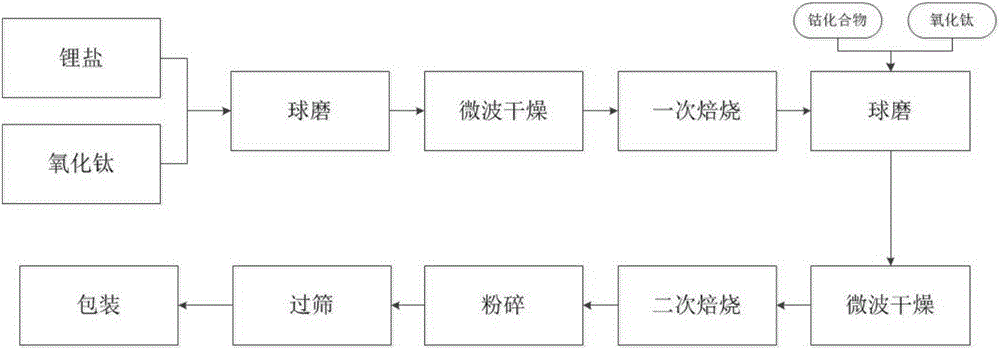

[0020] Such as figure 1 Shown, the preparation method of cobalt titanium green coated lithium titanate of the present invention comprises the following steps:

[0021] 1) Weigh lithium salt and titanium dioxide according to the molar ratio of lithium and titanium (0.78~0.84):1, and then weigh deionized water according to the mass ratio of deionized water to (titanium dioxide+lithium salt) as 3:1, and The above-mentioned substances are added into a sand mill for ball milling, and the particle size of the ball mill slurry is D 50 ≤0.2μm;

[0022] 2) Microwave drying the slurry obtained in step 1) at a drying temperature of 110-120°C;

[0023] 3) Roasting the material obtained in step 2) once at 700-900° C. for 8-24 hours to obtain a lithium titanate material;

[0024] 4) Weigh titanium dioxide and cobalt compounds according to the titanium and cobalt molar ratio of 1:2, wherein the quality of titanium dioxide: step 3) lithium titanate quality = 0.1% ~ 0.5%: 1, then according ...

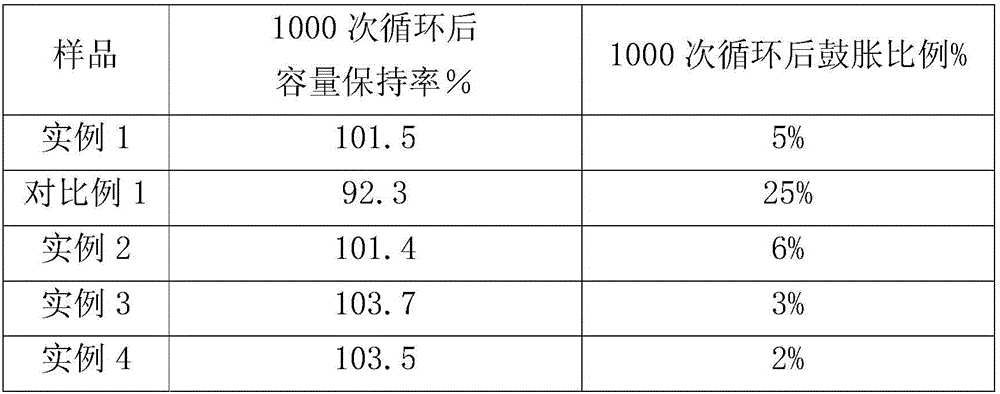

Embodiment 1

[0033] A preparation method of cobalt titanium green coated lithium titanate, comprising the steps of:

[0034] 1) Weigh lithium carbonate and titanium dioxide according to the molar ratio of lithium and titanium of 0.78:1, then weigh deionized water according to the mass ratio of deionized water to (titanium dioxide+lithium carbonate) as 3:1, and add the above-mentioned substances to sand Ball milling in the mill, ball milling slurry particle size D 50 = 0.18 μm;

[0035] 2) The slurry obtained in step 1) is subjected to microwave drying, and the drying temperature is 110° C.;

[0036] 3) Roasting the material obtained in step 2) once at 700° C. for 24 hours to obtain a lithium titanate material;

[0037] 4) Weigh titanium dioxide and cobalt tetraoxide according to the molar ratio of titanium and cobalt being 1:2, wherein the quality of titanium dioxide: step 3) lithium titanate quality = 0.1%: 1, and then according to deionized water and (titanium dioxide+cobalt tetroxide+...

Embodiment 2

[0044] A preparation method of cobalt titanium green coated lithium titanate, comprising the steps of:

[0045] 1) Take lithium hydroxide monohydrate and titanium dioxide according to the molar ratio of lithium and titanium being 0.80:1, then weigh deionized water according to the mass ratio of deionized water and (titanium dioxide+lithium hydroxide) as 3:1, and The above-mentioned substances are added into a sand mill for ball milling, and the particle size of the ball mill slurry is D 50 = 0.15 μm;

[0046] 2) The slurry obtained in step 1) is subjected to microwave drying, and the drying temperature is 110° C.;

[0047] 3) Roasting the material obtained in step 2) once at 900° C. for 8 hours to obtain a lithium titanate material;

[0048] 4) Weigh titanium dioxide and cobalt oxalate according to the molar ratio of titanium and cobalt being 1:2, wherein the quality of titanium dioxide: step 3) lithium titanate quality = 0.1%: 1, then according to deionized water and (titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com