Transparent conductive film

A technology of transparent conductivity and transparent conductive layer, which is applied in the direction of conductive layer, metal/alloy conductor, electrical digital data processing, etc. Speed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

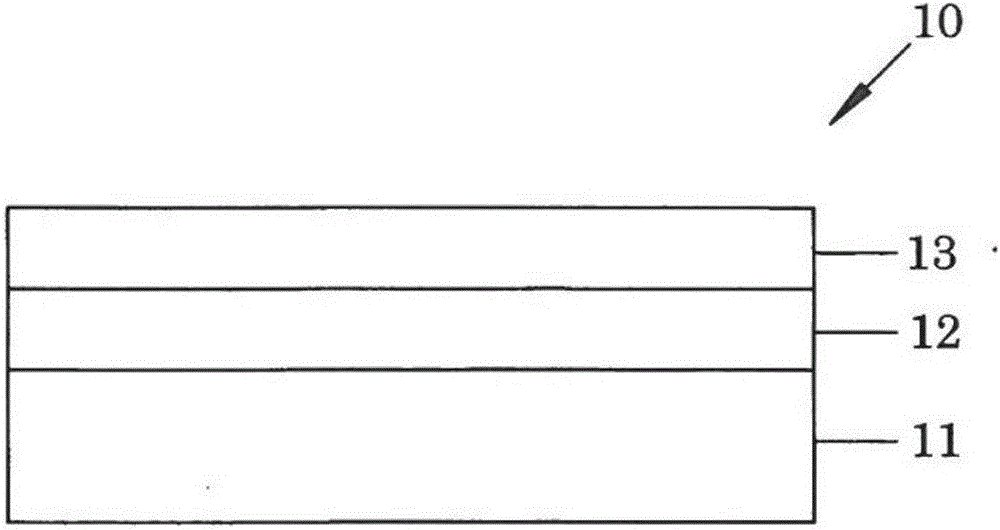

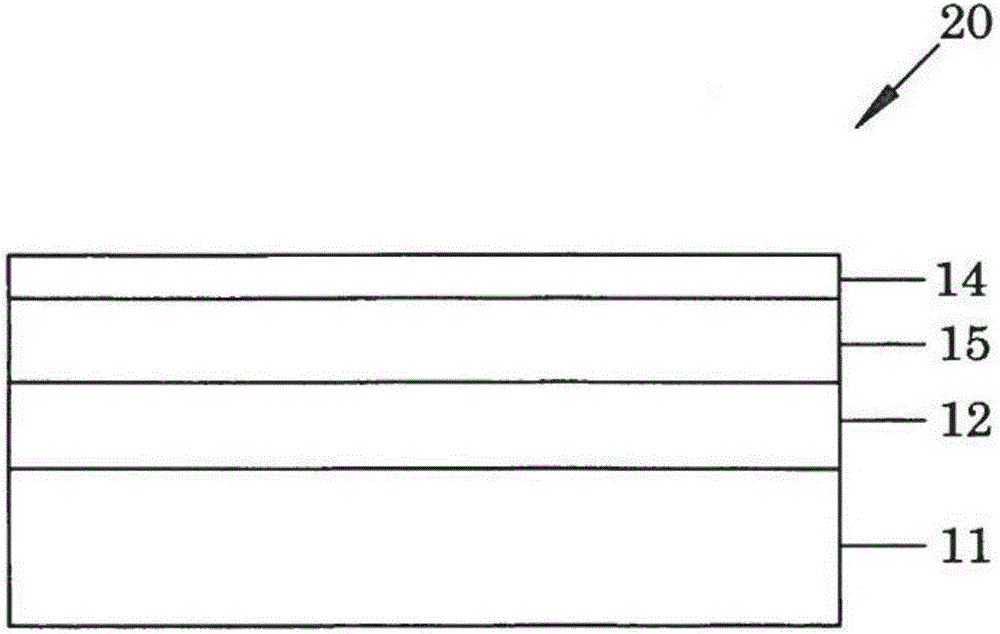

[0091] The transparent conductive film of Example 1 is figure 2 The layer structure shown in . The film substrate is a polyethylene terephthalate (PET) film with a thickness of 100 μm. The optical adjustment layer was composed of a silicon oxide layer formed by sputtering, and had a thickness of 20 nm. The first transparent conductive thin layer was composed of a first indium tin oxide (ITO) layer (thickness 3 nm), and the second transparent conductive thin layer was composed of a second indium tin oxide (ITO) layer (thickness 19 nm). The content ratio of tin (impurity metal element) to indium in the first indium tin oxide layer (first transparent conductive thin layer) (the atomic ratio Sn / In of the number of Sn atoms to the number of In atoms) was 0.03, and the first The content ratio of tin (impurity metal element) to indium in the indium tin oxide layer (second transparent conductive thin layer) (the atomic ratio Sn / In of the number of Sn atoms to the number of In atoms...

Embodiment 2

[0103] Except that the thickness of the first indium tin oxide layer (first transparent conductive thin layer) was 6 nm, and the thickness of the second indium tin oxide layer (second transparent conductive thin layer) was 16 nm, In the same manner as in Example 1, the transparent conductive film of Example 2 was produced.

Embodiment 3

[0105] Except that the thickness of the first indium tin oxide layer (first transparent conductive thin layer) was 8 nm, and the thickness of the second indium tin oxide layer (second transparent conductive thin layer) was 14 nm, In the same manner as in Example 1, the transparent conductive film of Example 3 was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com