A kind of titanium alloy for preparing impeller and its preparation method

A technology of titanium alloy and impeller, which is applied in the field of titanium alloy for impeller preparation and its preparation, to achieve the effects of easy metal internal flow, good weight reduction effect, and improved high temperature resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

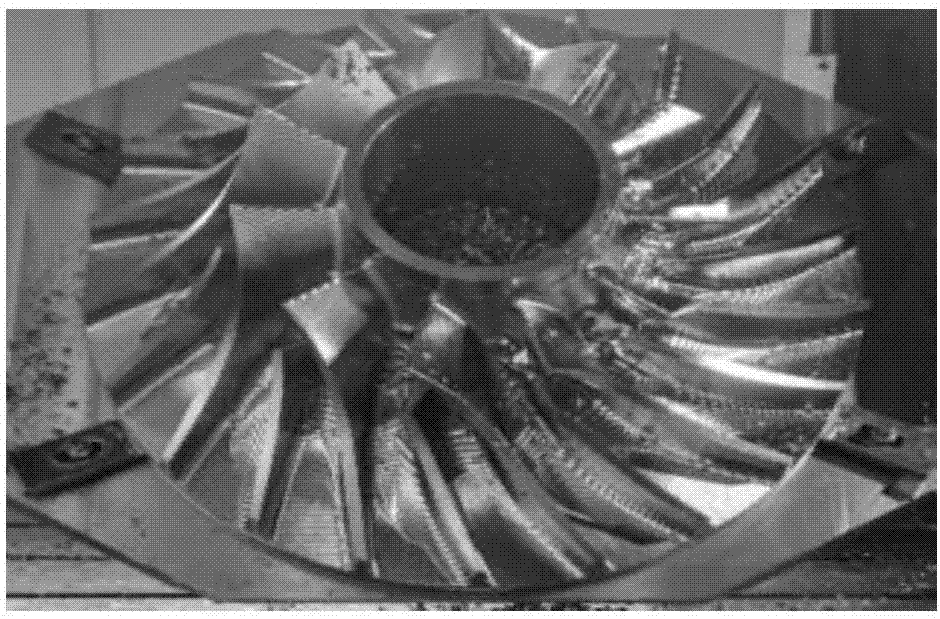

Image

Examples

Embodiment 1

[0021] Based on Ti-6Al-4V as the benchmark, set Ti-6.5Al-4.2V, according to Al: 6.5%; V: 4.2%; Fe: 0.27%; Si: 0.07%; Zr: 0.07%; Mo: 0.07%; C: 0.07%; N: 0.015%; H: 0.001%; O: 0.15%, and the remainder is the set amount of Ti to prepare the material. Prepare Al skin, Al beans, titanium sponge, powders of various metal elements, graphite and titanium dioxide according to the measurement, and put various materials into the distributing machine for full mixing. The total weight after mixing was 380 kg. The particle size of sponge titanium is 0.254-25.4mm; the alloy is put into the mold of the vertical hydraulic press to extrude the electrodes, and the weight of each electrode is 45Kg; 9 electrodes are shared and smelted in a conventional way in a vacuum furnace for Φ380 *L, Φ480*L and Φ580*L are smelted three times into ingots of Φ580*1700mm; the smelted ingots weigh 1.65t. After the flaw detection, the riser and bottom of the head were sawed to Φ560*1400mm, and the weight was 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com