Method and apparatus for separating particles in lubricating oil based on micro-fluidic chip

A microfluidic chip and particle separation technology, which is applied in the direction of measuring devices, analyzing materials, and material analysis by electromagnetic means, can solve the inaccuracy of quantitative ferrography that cannot fully meet the detection requirements of low cost, fast, and sensitive , non-representative and other issues, to achieve the effect of simple design, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

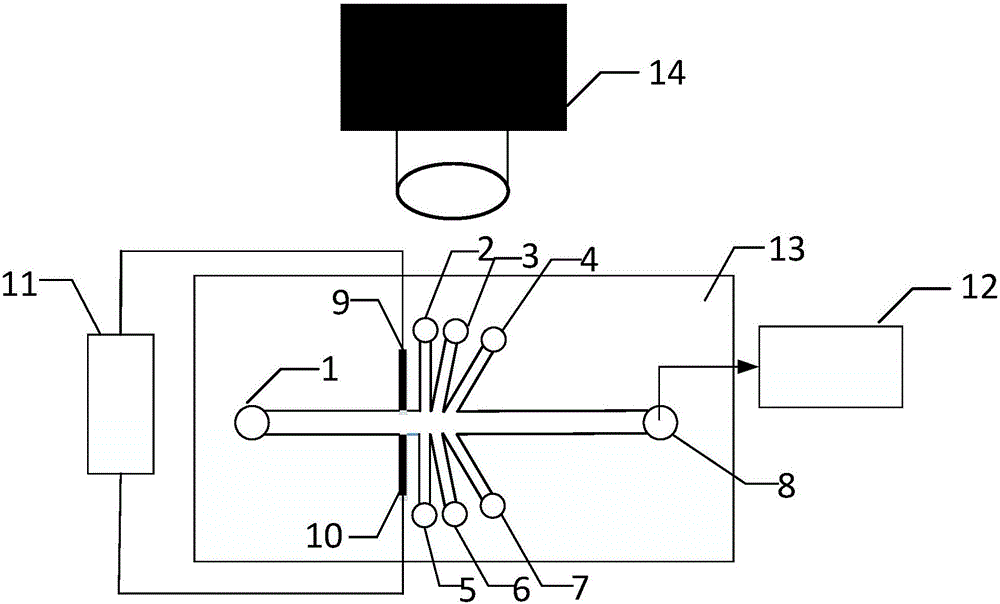

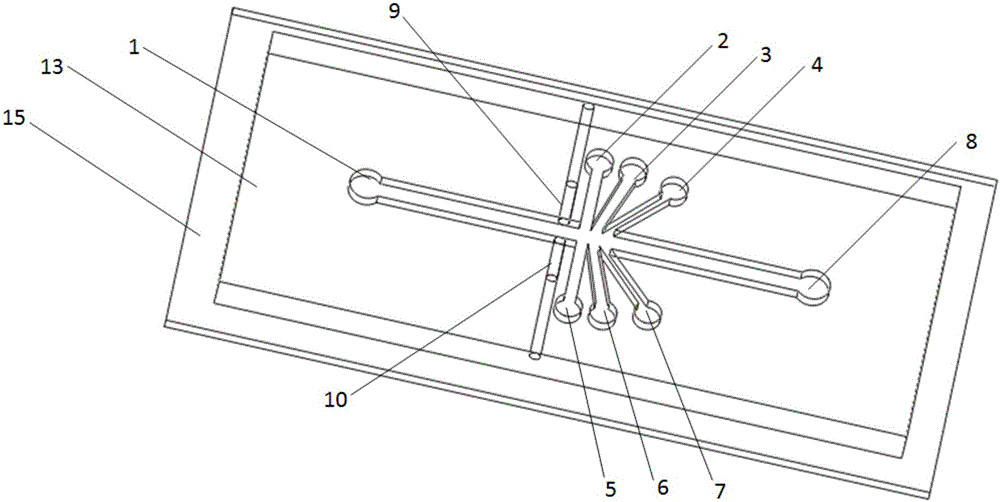

[0044] Such as figure 1 Shown is a device based on the separation of metal particles and non-metal particles in lubricating oil based on microfluidic chips. It is mainly composed of a microfluidic chip, copper electrodes, an external power supply module 11, a micro-injection pump 12, and an LED ultraviolet lamp 14 with a suitable frequency. Such as figure 2 As shown, it is a schematic structural view of the microfluidic chip main body 13 and the substrate 15, wherein the microfluidic chip main body 13 is made of PDMS (polydimethylsiloxane) material, and the substrate 15 is made of PMMA (polymethylmethacrylate ), that is, plexiglass. There is good adhesion between PDMS (polydimethylsiloxane) material and PMMA material, and it has good chemical inertness. There is one main channel on the main body of the microfluidic chip, which is a channel for detecting oil samples; the other is a separation channel symmetrically arranged on both sides of the main channel for separating me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com