Composite separation membrane and preparation method thereof

A separation membrane and polymer technology, applied in structural parts, electrical components, battery pack components, etc., can solve the problem of insufficient wettability of non-aqueous electrolytes, and achieve the effect of reduced thickness and high capacity charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

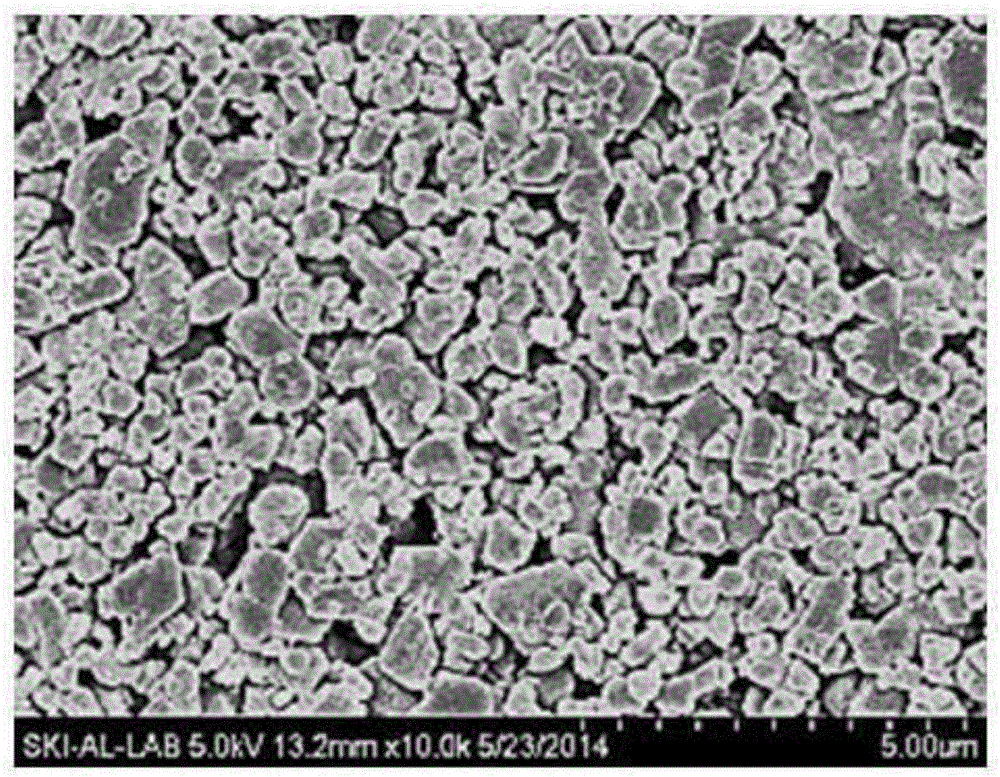

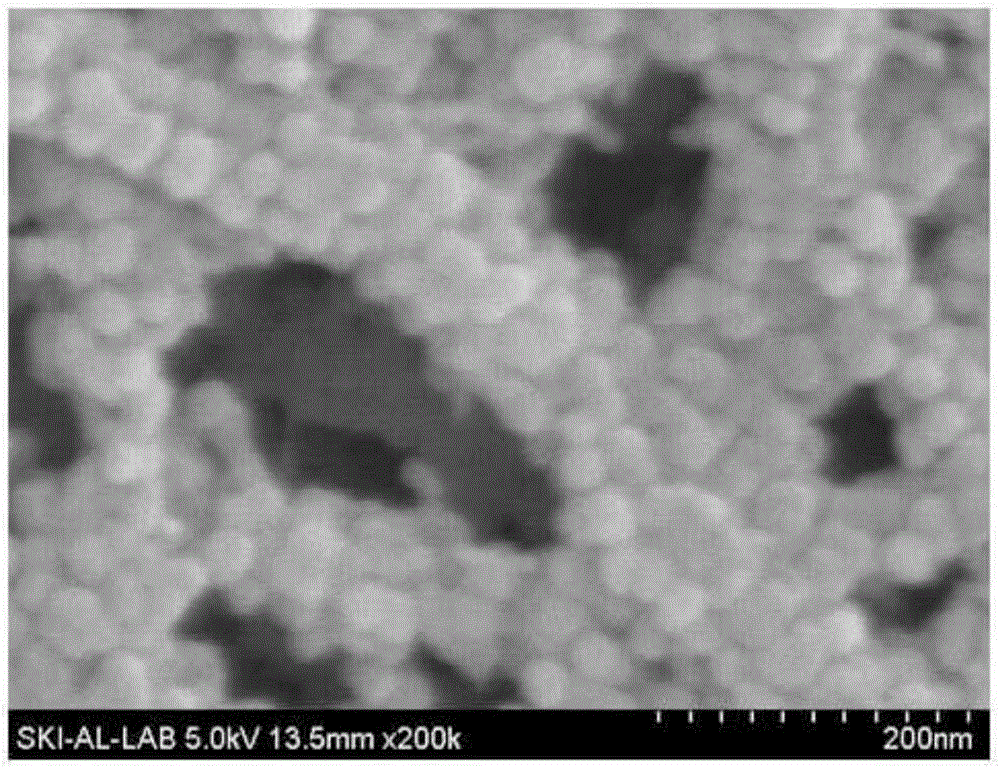

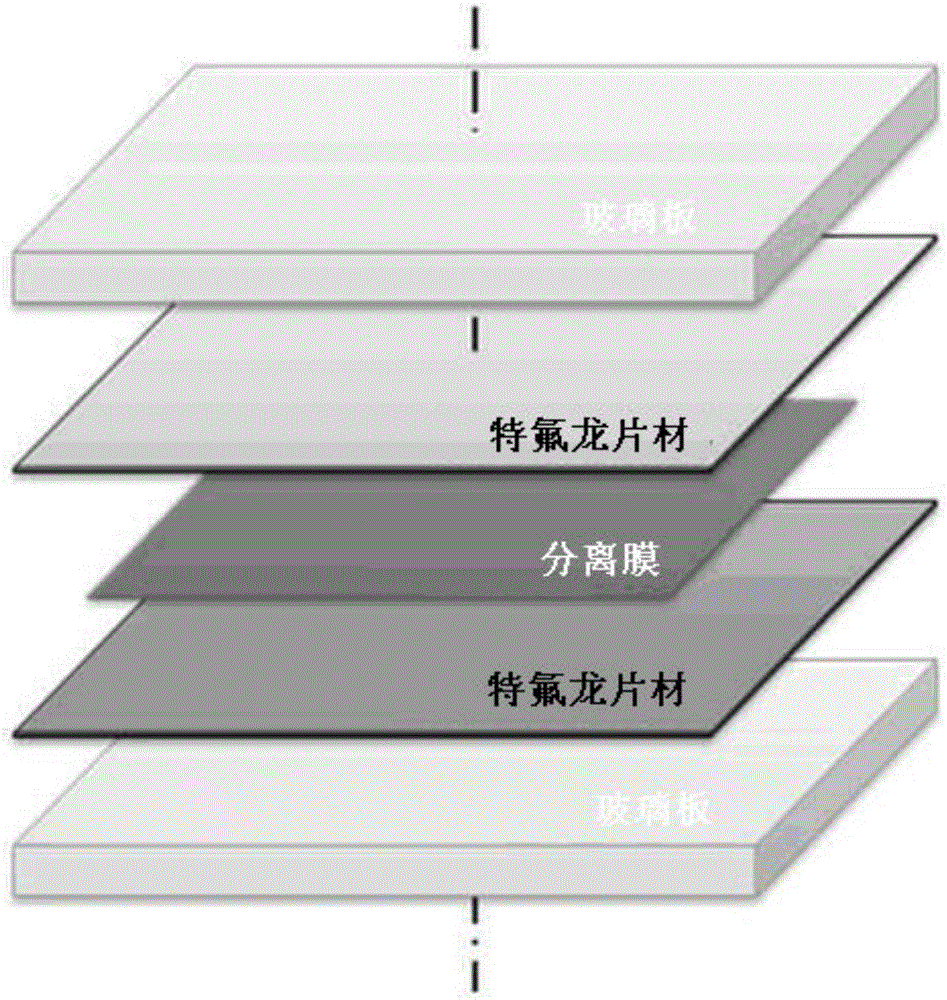

[0039] In addition, the present invention provides a novel composite separation membrane that is remarkably excellent in charge and discharge efficiency and excellent in heat resistance and mechanical strength, and a preparation method thereof, the composite separation membrane comprising a porous substrate; A metal precursor is laminated on a porous substrate, and then a reactant is used to form one or two or more metal compound layers, and then a ceramic layer is formed on top of it.

[0040] In addition, the present invention provides a composite separation membrane capable of increasing battery capacity and a preparation method thereof. The increase in battery capacity is achieved through the following methods. After corona discharge treatment or plasma discharge treatment is performed on the surface of the porous polymer substrate, metal compound layer or porous polymer substrate and metal compound layer, a ceramic layer is formed on the upper part, thereby improving the p...

Embodiment 1

[0103] In order to prepare polyolefin-based microporous membranes, a weight-average molecular weight of 3.8×10 5 High-density polyethylene, dibutyl phthalate mixed in a ratio of 1:2 and paraffin wax with a kinematic viscosity of 160cSt at 40°C are used as diluents, and the contents of polyethylene and diluents are 30% by weight and 70% by weight, respectively. %. The composition was extruded at a temperature of 240° C. using a twin-screw laminator equipped with a T-die, and phase separation was induced through a zone set at 180° C., and formed into a sheet using casting rolls. It is produced by successive biaxial stretching with the stretching ratio MD and TD being 7.5 times and the stretching temperature being 131°C. The heat setting temperature is 130°C and the heat setting width is 1, 1.3 and 1.1. And made. The resulting separation membrane had a final thickness of 25 μm, a gas permeability of 100 sec, and longitudinal and transverse shrinkages at 130° C. of 25% and 28%, ...

Embodiment 2

[0107] In Example 1, in addition to using a coaxial (in-line) oxygen plasma device, with the following conditions, that is, 1.9kw, the distance between the substrate and the plasma slit (slit) is 3mm, and the plasma slit gap (slit gap) is The porous polymer substrate was treated in the same manner as in Example 1, except that the porous polymer substrate was treated at a line speed of 2 mm and a line speed of 3 m / min. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com