Tea blending and egualizing machine

A blending machine and tea technology, applied in tea processing before extraction, etc., can solve the problems of manual labor intensity and workload, poor hygienic conditions of manual blending operations, uneven blending ratio, etc., to achieve high production efficiency, Easy equipment maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

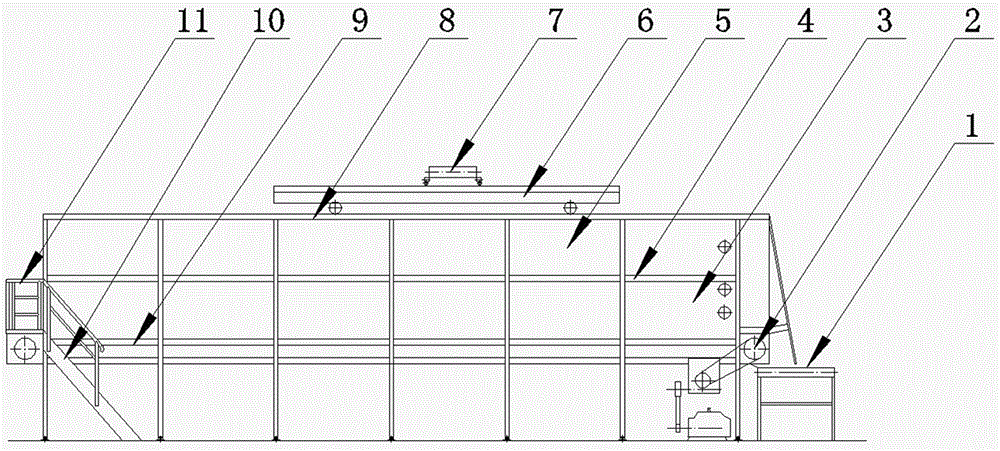

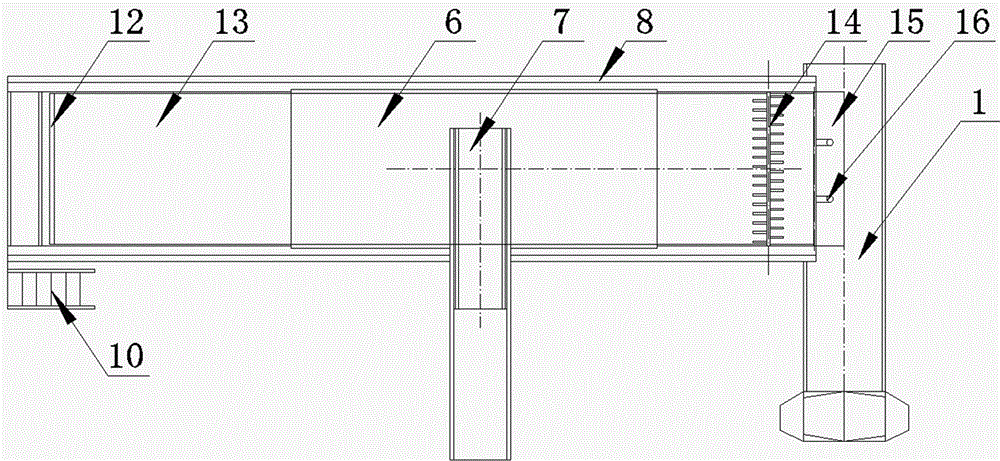

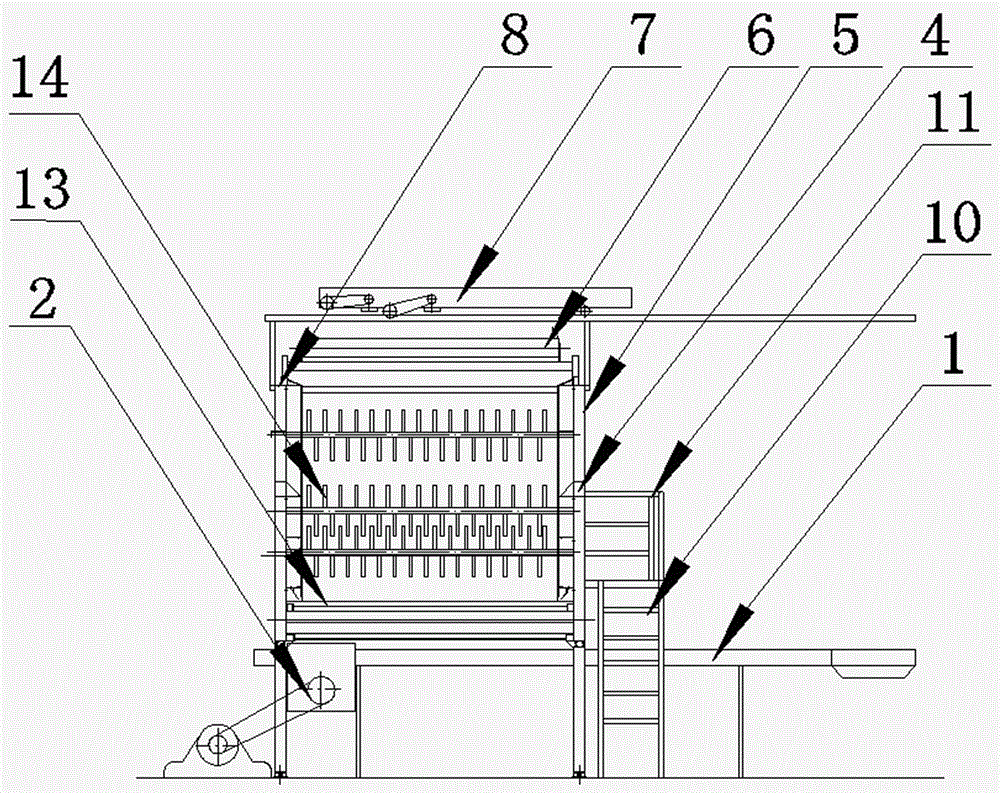

[0009] The present invention will be further described below in conjunction with the specific embodiments of the accompanying drawings. (but not limitation of the invention).

[0010] As shown in the figure, the tea evenly piled blending machine is equipped with a discharge conveyor 1, a gear motor traction device 2, a box body 3, a cloth driving vehicle 6, a feeding driving vehicle 7, a driving guide rail 8, and a stacking conveyor 9 , maintenance stairs 10, inspection platform 11, stacking baffle 12, stacking conveyor belt 13, tea rake 14, discharge bin door 15, door opening solenoid valve cylinder 16, the box body 3 is assembled on the I-beam bracket 4 The stainless steel plate 5 forms a rectangular box body 3, which is used to store the tea leaves that are sprinkled when they are evenly stacked and blended; two driving sliding guide rails 8 are installed on the upper edge of the box body 3, and a cloth driving vehicle 6 is set up on the guide rails 8. The described The fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com