Functional sugar-free mint and preparation method thereof

A functional and mint candy technology, which is applied to the functions of food ingredients, confectionary, confectionary industry, etc., can solve the problems of insufficient effect and insufficient research on probiotic candy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A functional sugar-free mint, raw materials:

[0031] Lactobacillus acidophilus, Lactobacillus salivarius, Lactobacillus reuteri three kinds of probiotic mixed bacteria powder 450g, containing the total number of viable bacteria 2.3)10 12 , of which the number of viable Lactobacillus acidophilus is 1×10 12 , Lactobacillus salivarius viable count 5×10 11 pcs, live Lactobacillus reuteri count 3×10 11 Each, inulin 2kg, xylitol 18kg, sorbitol 70kg, natural menthol 500g, magnesium stearate 1.8kg.

[0032] Preparation:

[0033] (1) Initial mixing and granulation: first filter xylitol, sorbitol, natural menthol, and inulin into the mixer with a 30-mesh stainless steel screen, add 11L of 60% vol edible alcohol evenly during the mixing process, and stir After 15 minutes, use a 20-mesh granulation shaker for granulation, then transfer to a constant 70°C oven for drying for 6 hours, and then perform secondary granulation when the temperature is lowered to 30°C;

[0034] (2) T...

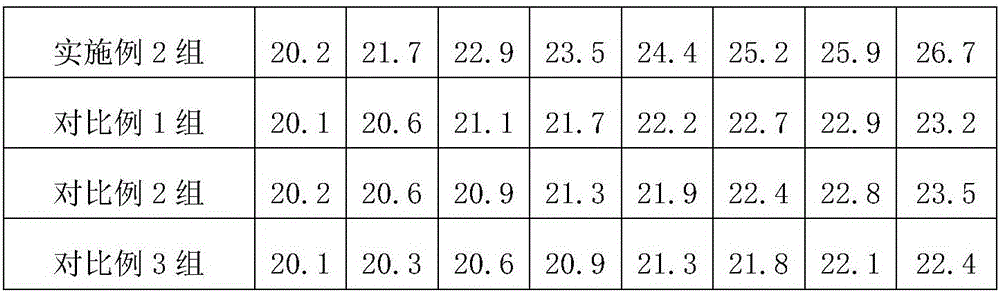

Embodiment 2

[0037] A functional sugar-free mint, raw materials:

[0038] Lactobacillus acidophilus, Lactobacillus salivarius, Lactobacillus reuteri three kinds of probiotic mixed bacteria powder 400g, containing the total number of viable bacteria 2.0×10 12 , of which the number of viable Lactobacillus acidophilus is 1.5×10 12 , live Lactobacillus salivarius count 4×10 11 pcs, live Lactobacillus reuteri count 4×10 11 Each, inulin 2.5kg, xylitol 20kg, sorbitol 75kg, natural menthol 600g, magnesium stearate 1.5kg. Preparation:

[0039](1) Initial mixing and granulation: first filter xylitol, sorbitol, natural menthol, and inulin into the mixer with a 30-mesh stainless steel screen, add 11L of 60% vol edible alcohol evenly during the mixing process, and stir After 15 minutes, use a 20-mesh granulation shaker for granulation, then transfer to a constant 70°C oven for drying for 6 hours, and then perform secondary granulation when the temperature is lowered to 30°C;

[0040] (2) Total mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com