A closed-circuit internal circulation device for gas collection in the process of solid-liquid separation

A technology of solid-liquid separation and internal circulation, applied in combined devices, separation methods, dispersed particle separation, etc., can solve problems such as environmental pollution, increased post-processing difficulty, inclusion of atomized droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

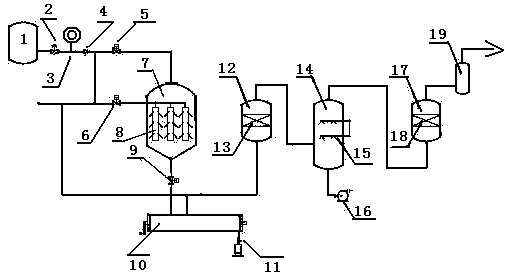

[0037] Connect the gas outlet of the compressed gas storage tank to the top air inlet and clear liquid outlet of the cluster type backflush filter, connect the slag outlet of the cluster type backflush filter to the top inlet of the slurry dryer, and connect the discharge port of the slurry dryer The slag outlet is connected to the inlet of the slag conveyor, the outlet of the slurry dryer is connected to the inlet of the first-stage gas-liquid separator, and the outlet of the first-stage gas-liquid separator is connected to the inlet of the gas scrubber, and the gas scrubber The residual liquid discharge port of the gas scrubber is connected to the inlet of the transfer pump, the gas discharge port of the gas scrubber is connected to the inlet of the secondary gas-liquid separator, and the outlet of the secondary gas-liquid separator is connected to a high-efficiency gas filter; cluster type backflushing filter The internal filter element adopts a "6+1" metal support frame, in...

Embodiment 2

[0039] A working method of a closed-circuit internal circulation device for gas collection in a solid-liquid separation process, characterized in that it comprises the following steps:

[0040] The liquid containing solid particle impurities is separated from the solid and liquid through the cluster type backflushing filter to remove the solid particles. The solid particles are filtered from the outside to the inside through the filter element and form a filter cake on the surface of the filter element. When the filter cake reaches a certain thickness or the filter When a certain filtration pressure difference is reached, the filter cake needs to be removed online; firstly, the pressure discharge / drying valve is opened, and the cluster backflush filter uses compressed gas to discharge the residual liquid and filter cake from the filter element from the outside to the inside. Then open the filter backflush valve and slag discharge valve, perform instantaneous backflush from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com