Preparation method of benzene boric acidification affinity chromatography stationary phase for chitosan oligosaccharide separation

A chromatographic stationary phase, chitosan oligosaccharide technology, applied in separation methods, chemical instruments and methods, sugar derivative preparation, etc., can solve the problem of unsatisfactory separation effect, small number of chromatographic columns, and difficulty in obtaining high-purity single-component chitosan oligosaccharides. Sugar and other problems, to achieve the effect of novel structure, good separation effect and high degree of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

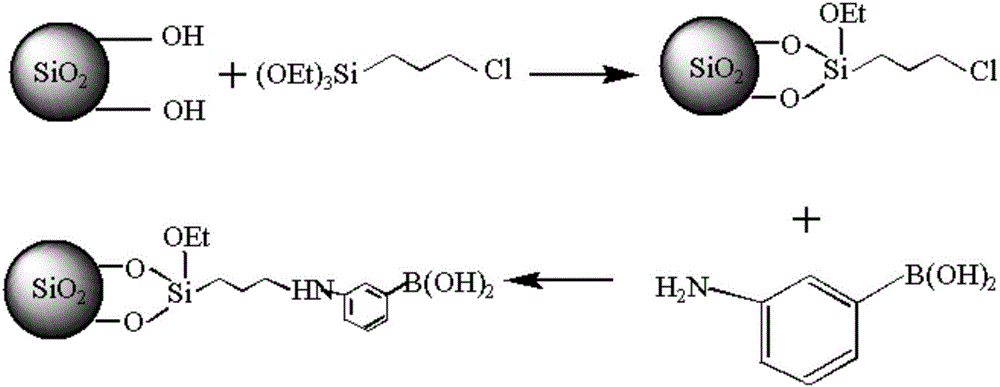

[0021] Specific embodiment one: a kind of preparation method of the phenylborated affinity chromatography stationary phase that is used for chitosan oligosaccharide separation described in this embodiment, specifically is carried out according to the following steps:

[0022] 1. Preparation of activated silica gel:

[0023] Add silica gel to hydrochloric acid solution with a volume percentage of 10% to 30%, and then reflux at a temperature of 100°C to 120°C for 5h to 8h, cool to room temperature after reflux, and wash the reacted silica gel with water until the washing liquid To be neutral, under the condition of temperature of 100℃~120℃, vacuum dry the washed silica gel for 8h~12h to obtain the activated silica gel;

[0024] The volume ratio of the mass of the silica gel to the volume percentage of 10%-30% hydrochloric acid solution is 1g:(20-50)mL;

[0025] 2. Preparation of chlorinated silica gel:

[0026] Put the activated silica gel in a round-bottomed flask, add N,N-di...

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass and volume percentage of the silica gel described in step 1 is 10% to 30% by volume of the hydrochloric acid solution, and the volume ratio is 1g: (35 ~ 50) mL . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mass ratio of activated silica gel described in step two to N,N-dimethylformamide is 1g:400mL . Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com