High-energy-efficiency piezoelectric ultrasonic transducer and end cover thereof

An ultrasonic transducer and effective piezoelectric technology, applied in the direction of the fluid using vibration, can solve the problem of uneven sound pressure distribution on the radiation surface, and achieve the effect of improving output energy efficiency, improving heating characteristics, and improving output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

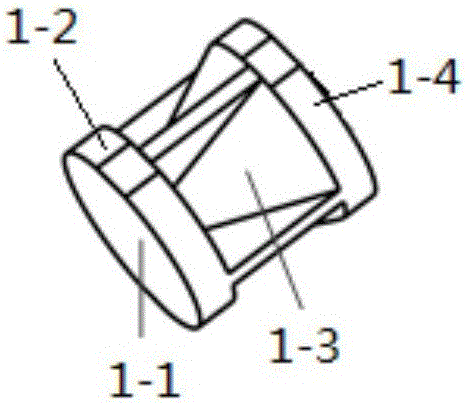

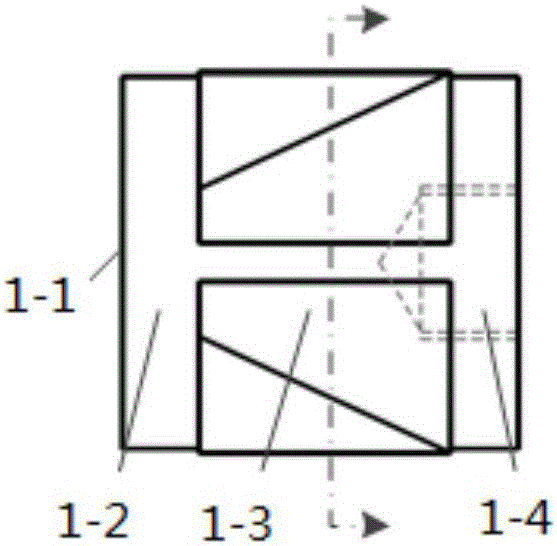

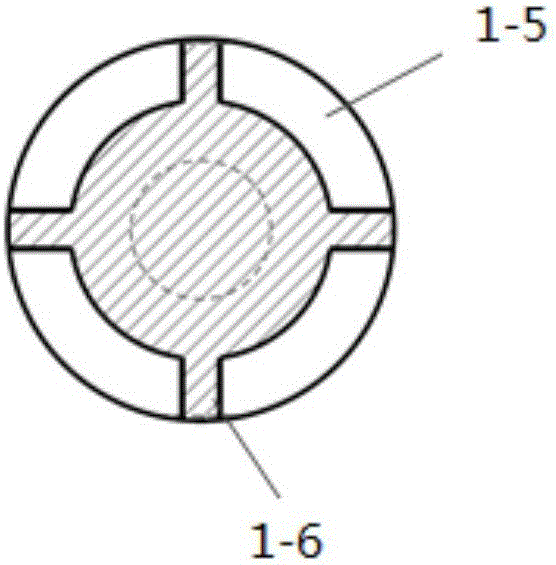

[0031] In order to improve the energy efficiency of the ultrasonic transducer, the present invention starts from optimizing the mass distribution of the cylindrical end cap of the ultrasonic transducer. In general, it is to reduce the mass load on the output end face of the cylindrical end cap. The end cover of the transducer has the following structure: the end cover has a cylindrical structure as a whole, but is divided into three parts, such as figure 1 , diagram 2-1 , 2-2 As shown, they are: the front part of the end cover 1-2, the middle part of the end cover 1-3 and the tail part of the end cover 1-4; wherein: the front part of the end cover 1-2 has an output end surface 1-1 for dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com