Instrument panel cross beam connection structure and vehicle

A technology for connecting structures and dashboards, applied in the field of vehicles, can solve the problems of complicated welding process, heavy weight, and threats to the personal safety of passengers, so as to achieve the effect of protecting personal safety, reducing safety threats, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

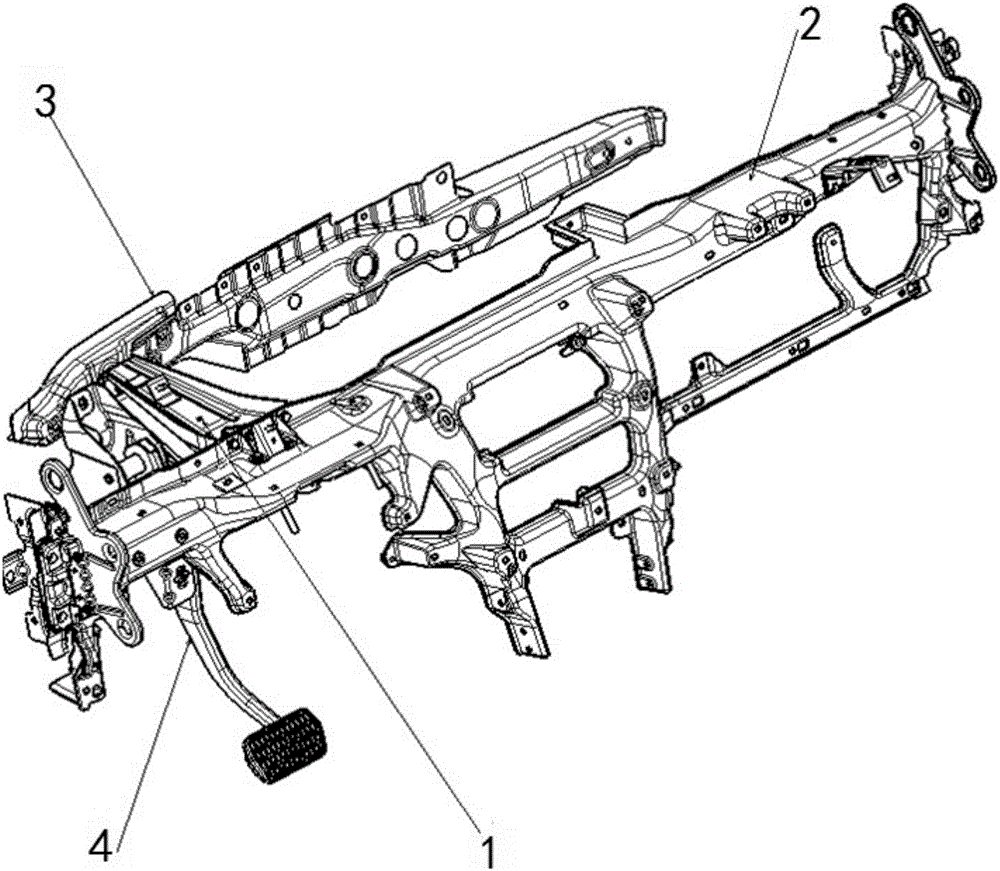

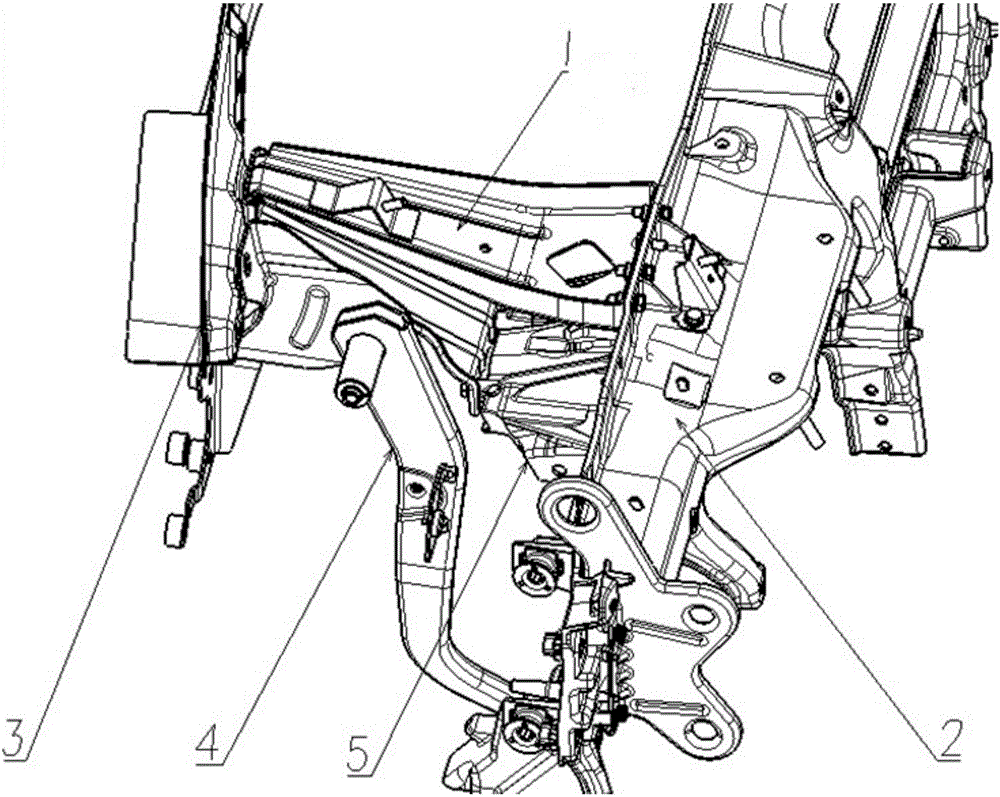

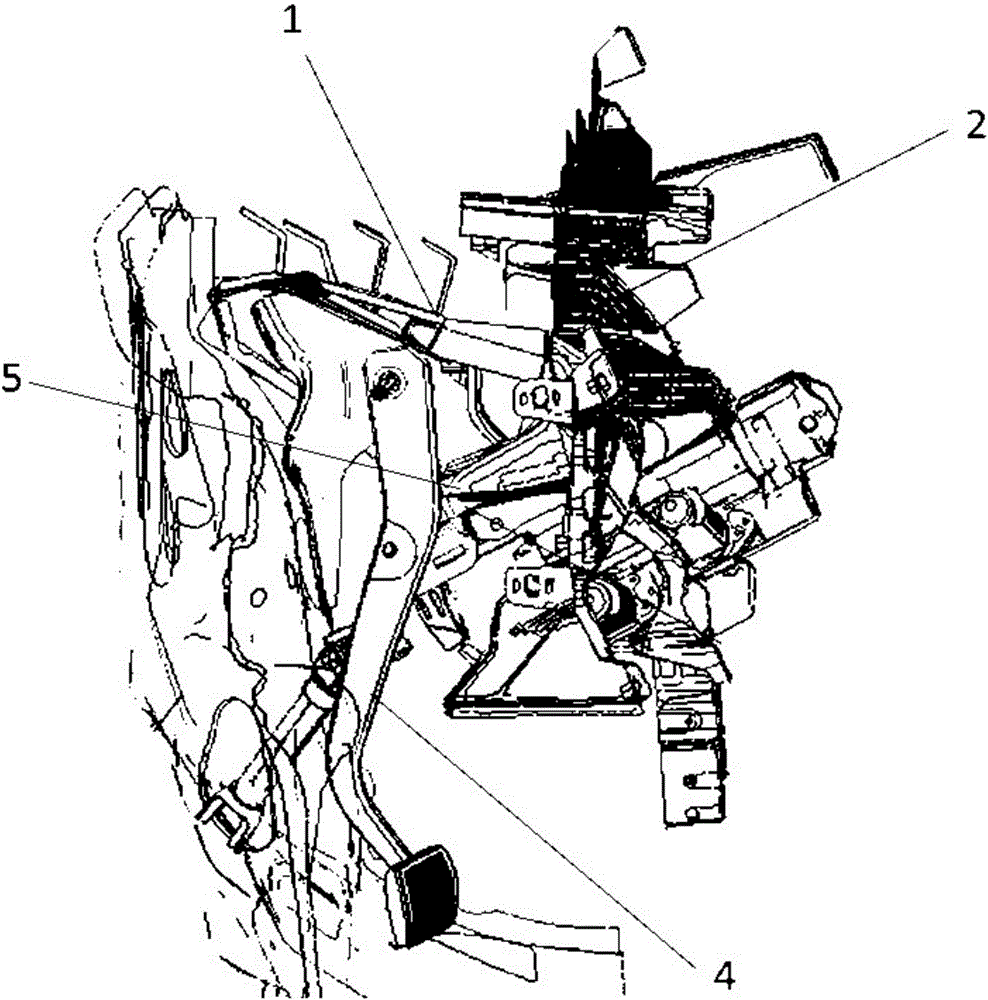

[0037] figure 1 It is a schematic perspective view of the instrument panel beam connection structure applicable to vehicles according to an embodiment of the present invention. combine figure 1 To illustrate, the instrument panel beam connecting structure for a vehicle may include: an instrument panel beam main body 2 , a cowl panel 3 and a front bracket 1 .

[0038] The cowl panel 3 may be the vehicle body cowl panel of the vehicle.

[0039] The dashboard beam body 2 may be used to support dashboard system components of the vehicle. The cowl panel 3 may be arranged in front of the instrument panel beam main body 2 in the direction toward the front of the vehicle. The front bracket 1 can be used to prevent the instrument panel beam main body 2 from being cracked or broken when the vehicle is hit. The front bracket 1 can connect and support the instrument panel beam main body 2 and the front wall panel 3 when the vehicle is in a non-collision state so as to improve the moda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com