Water treatment system

A water treatment system and water outlet technology, applied in the field of water treatment, can solve the problems that the anaerobic flora and aerobic flora can not be used at the same time, and the A2/O occupies a large area, so as to save the occupied area, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

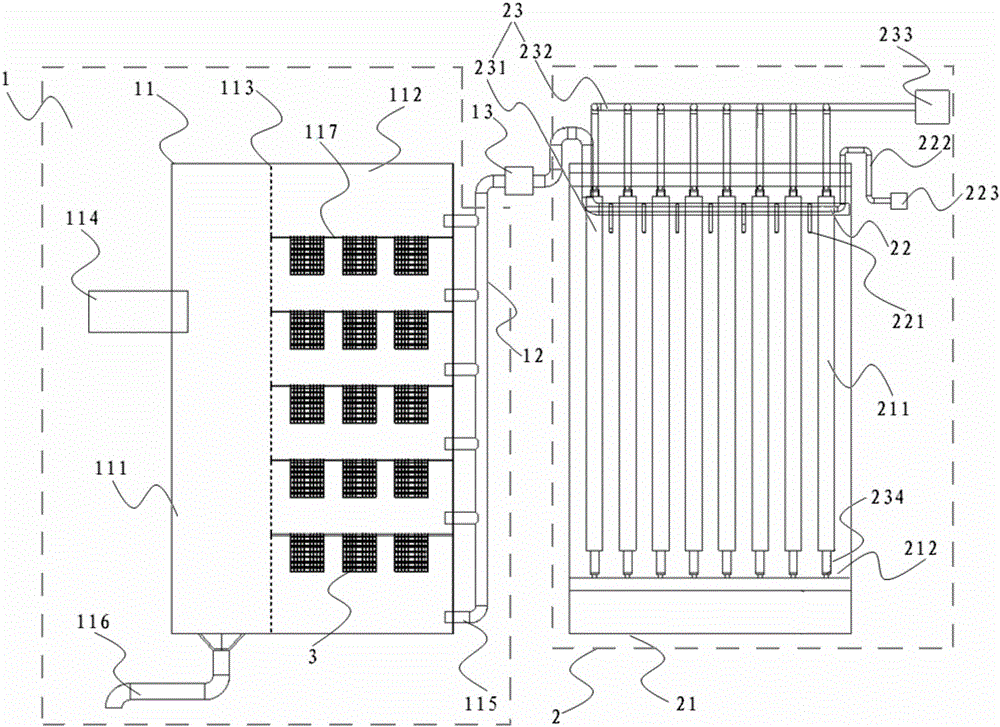

[0089] The wastewater is: wastewater from a printing and dyeing factory in Shaoxing City, Zhejiang Province: the effluent COD is 2800mg / L, and the total nitrogen is 65mg / L.

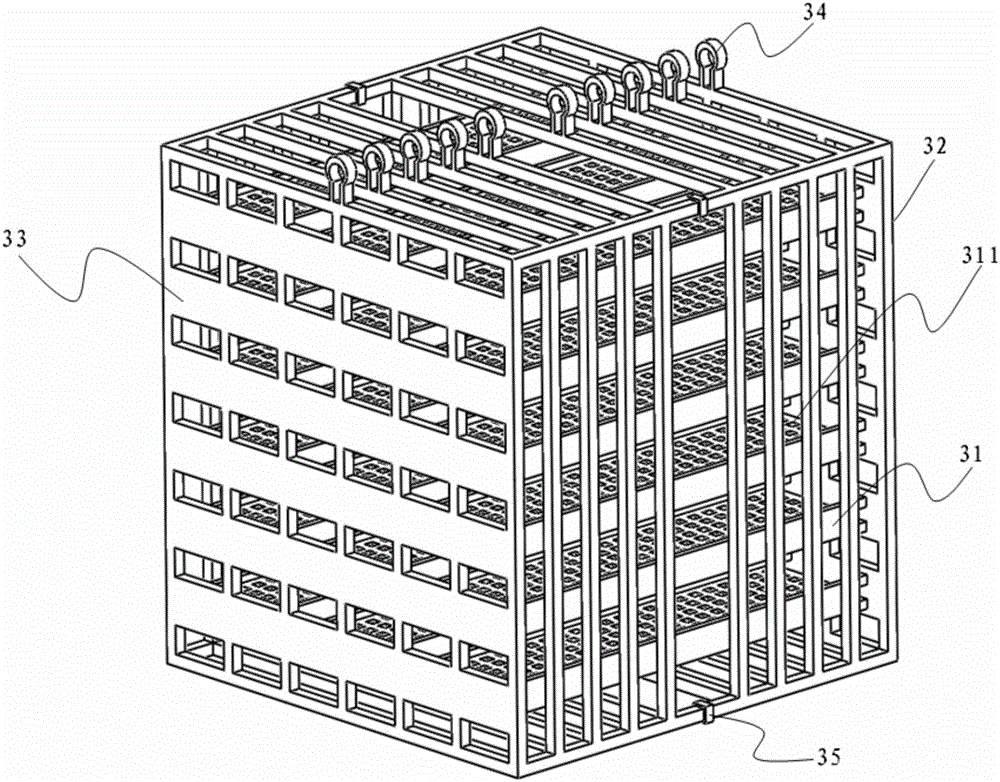

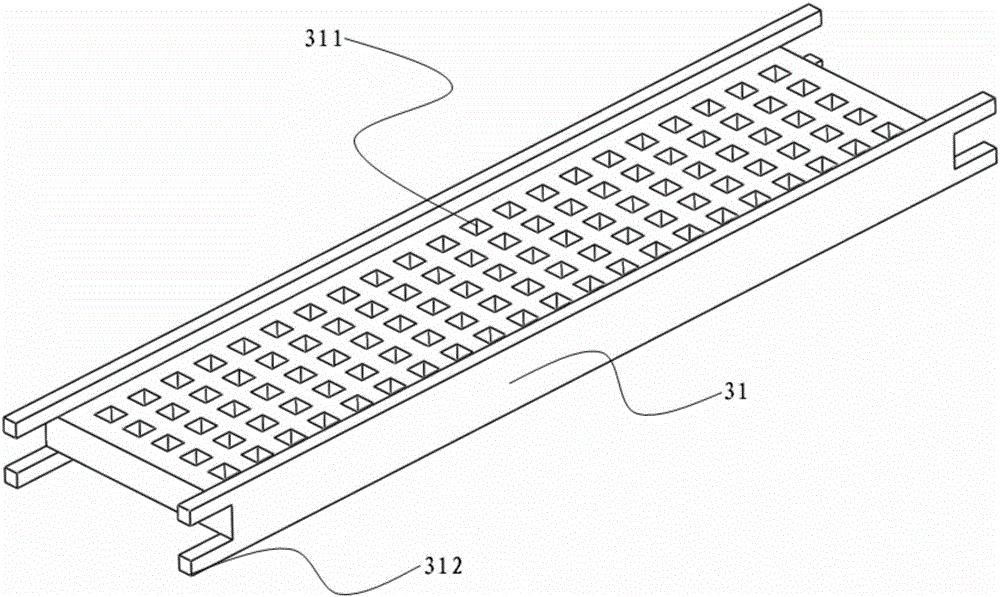

[0090] The structure of the anaerobic reaction device: the length of the anaerobic reaction tank is 7m, the width is 6m, the height is 15m, and the size of the grid gap of the fine grid is 10mm. The number of layers of fixed packing is 5 layers, and each layer of packing is divided into 2 rows, and the number of packing in each row is 3. The fixed packing is a cube with a side length of 1m, and the packing frame is made of polyvinylchloride (polyvinylchloride) after hydrophilic treatment. ), the material of the filler support is alumina, the hole area of the filler hole on the filler support accounts for 20% of the surface area of the filler support, and the microorganisms domesticated on the filler support are Thiobacillus denitrificans, Nitratereducing bacteria, A combination of Desulfotomaculum and...

Embodiment 2

[0095] The wastewater is: wastewater from a paper mill in Shanghai: the effluent COD is 4900mg / L, and the total nitrogen is 45mg / L.

[0096] The structure of the anaerobic reaction device: the length of the anaerobic reaction tank is 12m, the width is 9m, the height is 20m, and the size of the grid gap of the fine grid is 8mm. The number of layers of fixed packing is 6 layers, and each layer of packing is divided into 2 rows, and the number of packing in each row is 5. The fixed packing is a cube with a side length of 1.5m, and the packing frame is polystyrene ( polystyrene), the material of the packing support is metal iron material, the pore area of the packing hole on the packing support accounts for 35% of the surface area of the packing support, and the microorganisms domesticated on the packing support are Thiobacillus denitrificans and Nitratereducing bacteria. bacteria, usually bacteria that can reduce nitrate, belonging to the combination of denitrifying bacteria)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com