Butane-1 polymerization reaction kettle and butene-1 polymerization reaction heating method

A technology for polymerization reactors and polymerization reactions, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve the problems affecting the physical properties and quality of polybutene-1 , Reactor heat transfer, mass transfer difficulties and other problems, to achieve the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

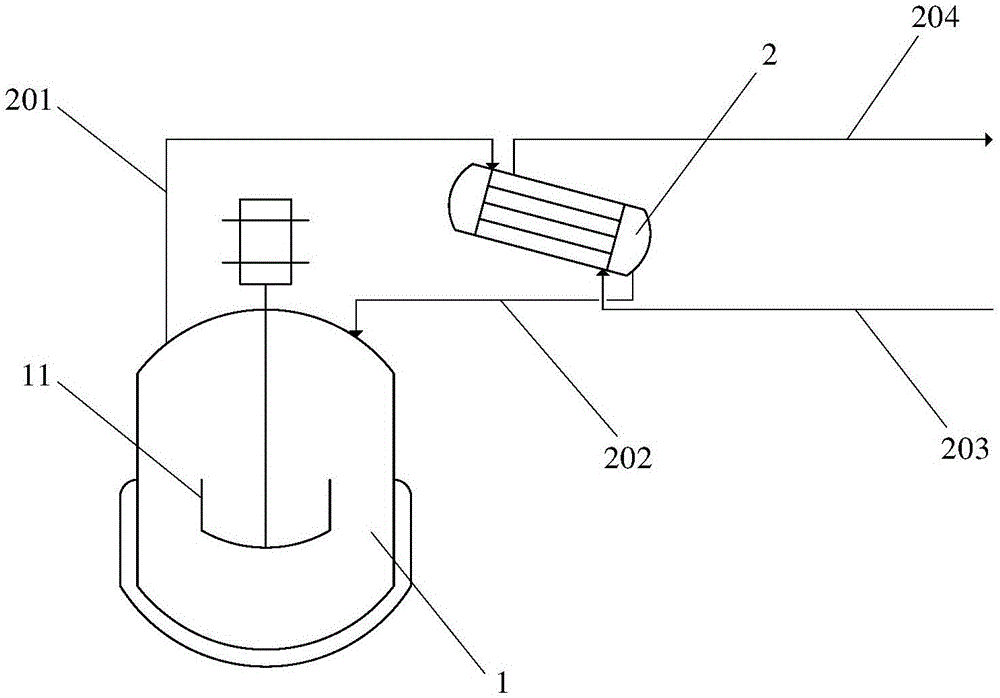

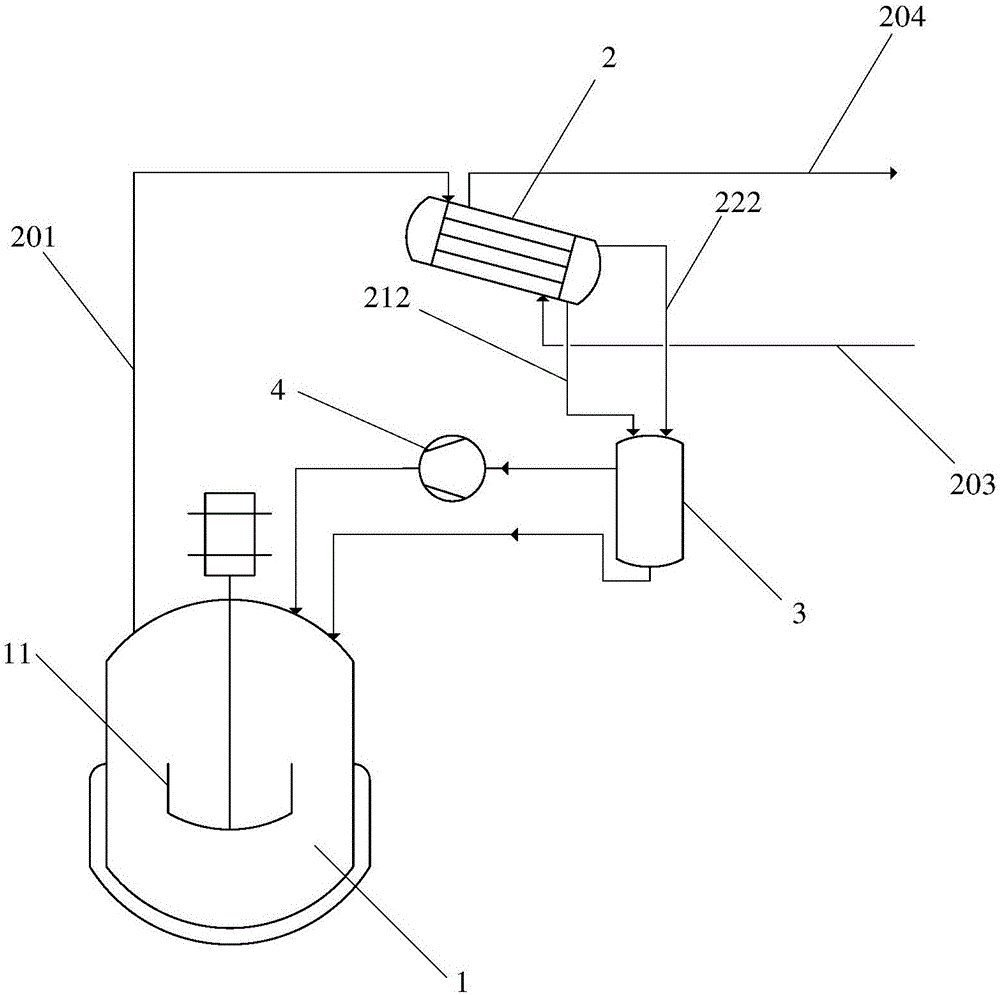

[0036] In order to further illustrate the butene-1 polymerization reactor and the heat extraction method for the butene-1 polymerization reaction provided in the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

[0037] see figure 1 , the butene-1 polymerization reactor provided by the embodiment of the present invention comprises a reactor body 1 and a condenser 2; The side is connected with the refrigerant circulation pipeline, the steam outlet of the reactor body 1 is connected with the heat release side inlet of the condenser 2 through the exhaust pipeline 201, and the heat release side outlet of the condenser 2 is connected with the reactor body 1 through the return pipeline 202 The return port is connected; among them,

[0038] The exhaust pipeline 201 is used to extract the saturated steam of the butene-1 polymerization reaction system in the reactor body 1, and the saturated steam contains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com