Xiaoqu baijiu brewing technology and device

A technology of Xiaoqu liquor and equipment, applied in the field of winemaking, can solve the problems of slow development of the brewing process, high labor intensity of workers, and great dependence on experience, and achieve the effects of increasing per capita productivity, reducing labor intensity, and eliminating influences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

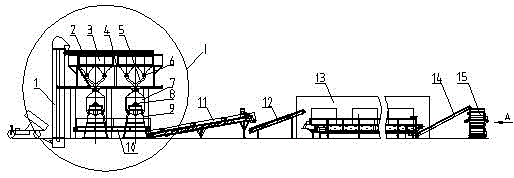

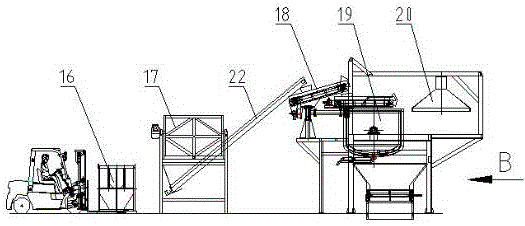

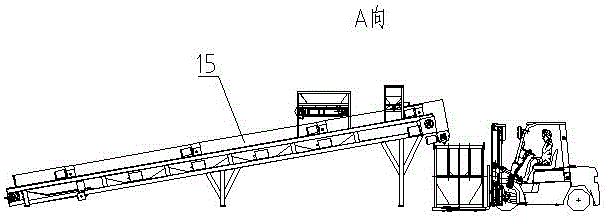

[0029] The solution of the present application will be described in detail below in conjunction with the drawings.

[0030] A brewing process for Xiaoqu liquor, including the following steps:

[0031] a. Raw material pretreatment, use the grain elevator and screw feeder to send the raw materials to the soaking hoppers, each soaking hopper is filled with 70~75℃ soaking water, soak the raw materials in the soaking water 20~24 hours, the condensed water of distilled wine can be used as grain water in actual production to save water resources and reduce costs;

[0032] b. The initial steaming is carried out in the low pressure cooking pot, the pressure in the pot is 0.1Mpa during the initial steaming, and the initial steaming time is 25~35min;

[0033] c. Adjust the pressure in the low-pressure cooking pot to normal pressure, and carry out normal pressure for 20 to 25 minutes;

[0034] d. Adjust the pressure in the low-pressure cooking pot to 0.05Mpa, and carry out continuous steaming unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com