Long-periodic structure phase reinforced Mg-RE-Ni magnesium alloy semi-solid-state blank and preparation method thereof

A long-period structure, semi-solid technology, applied in the field of metal materials, can solve the problems that have not been found in the semi-solid billet research report of long-period structure reinforced Mg-RE-Ni magnesium alloy, and achieve high roundness and semi-solid forming Effect of low temperature and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

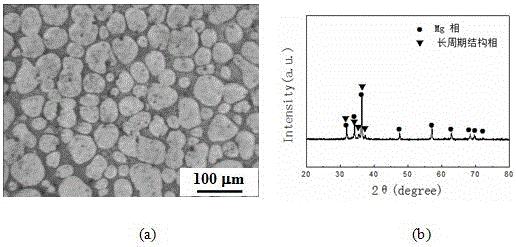

[0021] Example 1: Mg 97.3 Gd 2 Ni 0.7 A semi-solid magnesium alloy blank, which contains the following components (in atomic percentage): Mg: 97.3%, Gd: 2%, and Ni: 0.7%.

[0022] The preparation method of the semi-solid blank of the alloy is as follows:

[0023] Using pure Mg, pure Gd, and pure Ni as raw materials, according to Mg 97.3 Gd 2 Ni 0.7 Alloy formula ingredients; first melt Mg and raise the temperature to 760°C, then add pure Gd and pure Ni, then heat up to 790°C for 90 min, and stir evenly; then cool down to 690°C and hold for 5 min, then liquid metal It is cooled at a cooling rate of 30°C / s and solidified to obtain a master alloy ingot.

[0024] Thermal analysis of the master alloy ingot shows that the melting temperature of the long-period structure phase in the master alloy ingot is 537℃, while the melting temperature of the Mg phase is 585℃; it is higher than the melting temperature of the long-period structure phase and lower than the Mg phase. For the temperature ...

Embodiment 2

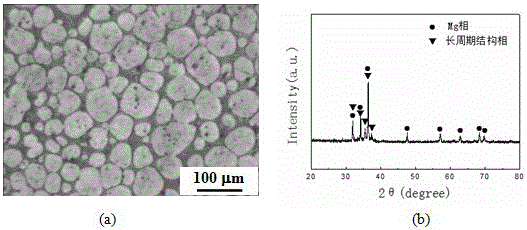

[0026] Example 2: Mg 97.3 Gd 1 Y 1 Ni 0.7 Magnesium alloy semi-solid billet, the billet contains the following composition (in atomic percentage): Mg: 97.3%, Gd: 1%, Y: 1%, Ni: 0.7%.

[0027] The preparation method of the semi-solid blank of the alloy is as follows:

[0028] Using pure Mg, pure Gd, pure Y, and pure Ni as raw materials, according to Mg 97.3 Gd 1 Y 1 Ni 0.7 Alloy formula ingredients; first melt Mg and raise the temperature to 760℃, then add pure Gd, pure Y and pure Ni, then heat up to 790℃ for 90 min, and stir evenly; then cool to 690℃ for 5 min, then The liquid metal is cooled at a cooling rate of 30°C / s and solidified to obtain a master alloy ingot.

[0029] Thermal analysis of the master alloy ingot shows that the melting temperature of the long-period structural phase in the master alloy ingot is 545℃, while the melting temperature of the Mg phase is 583℃; it is higher than the melting temperature of the long-period structural phase and lower than the Mg phase. Fo...

Embodiment 3

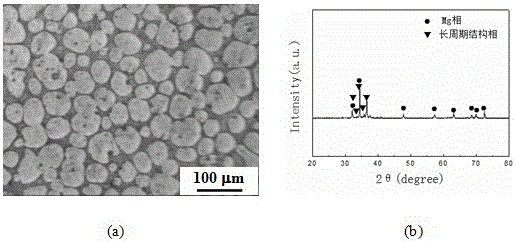

[0031] Example 3: Mg 97.3 Y 2 Ni 0.7 Magnesium alloy semi-solid billet, the billet contains the following composition (in atomic percentage): Mg: 97.3%, Y: 2%, Ni: 0.7%.

[0032] The preparation method of the semi-solid blank of the alloy is as follows:

[0033] Using pure Mg, pure Y, and pure Ni as raw materials, according to Mg 97.3 Y 2 Ni 0.7 Alloy formula ingredients; first melt the Mg and raise the temperature to 760°C, then add pure Y and pure Ni, then heat up to 790°C for 90 minutes, and stir evenly; then cool to 690°C and hold for 5 minutes, then melt the metal liquid It is cooled at a cooling rate of 30°C / s and solidified to obtain a master alloy ingot.

[0034] Thermal analysis of the master alloy ingot shows that the melting temperature of the long-period structural phase in the master alloy ingot is 552℃, while the melting temperature of the Mg phase is 595℃; it is higher than the melting temperature of the long-period structural phase and lower than the Mg phase. For th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com