Mat rush viscose fibers and preparation method thereof

A viscose fiber and rush technology, which is applied in the field of viscose fiber containing rush and its preparation, can solve the problems of viscose staple fiber not obvious characteristics, less output, low pulping rate, etc., and achieve excellent natural antibacterial Function, large economic and social benefits, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take a certain amount of rush powder and add it into water at a temperature of 25°C in a ratio of 500g / L to dissolve, stir until the dissolution is complete, and make an aqueous solution of rush powder.

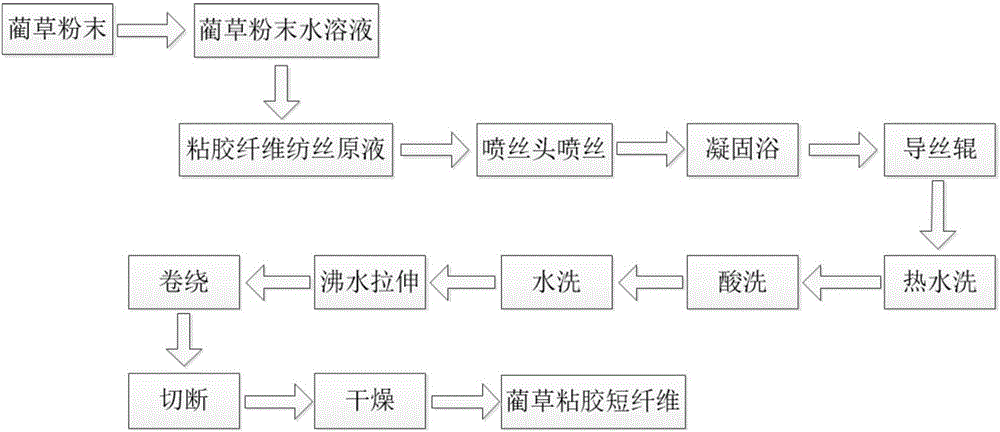

[0032] The obtained rush powder aqueous solution is added to the viscose spinning stock solution with a fiber mass fraction of 10% in the proportion of 10% of the mass of the viscose fiber spinning stock solution, stirred and dispersed, left to stand for vacuum degassing, and then according to the conventional wet method Spinning and spinning process, enter coagulation bath through candle filter and spinneret after measuring by metering pump; Described coagulation bath is made up of 100g / L sulfuric acid, 320g / L sodium sulfate and 15g / L zinc sulfate, and temperature is 40 ℃, the elongation rate is 100%, the spinning speed is 50m / min, and then sprayed according to the conventional wet spinning process, and then the rush viscose fiber is obtained through the oiling and dry...

Embodiment 2

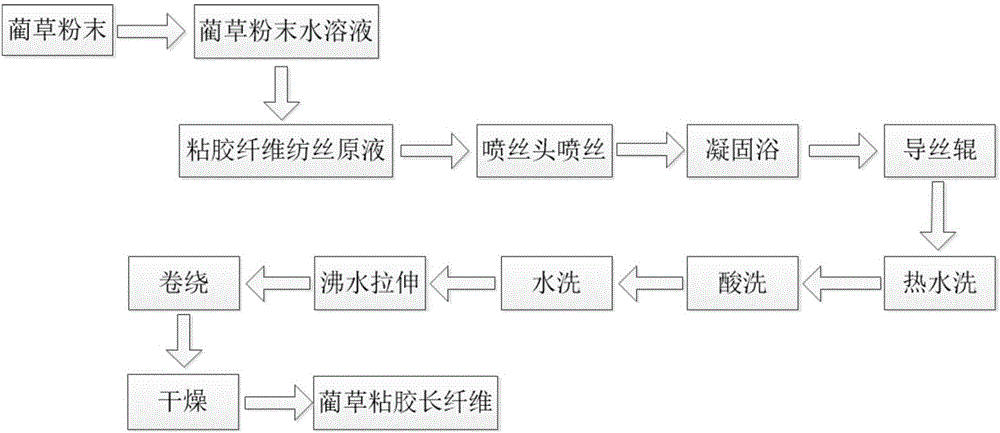

[0035] Such as image 3 Shown, a kind of improvement to above-mentioned preparation method: obtain rush viscose long fiber and adopt the spinneret molding process of conventional wet spinning long filament to comprise the following steps: rush grass powder aqueous solution and viscose fiber spinning stock solution blending—> Spinneret spinning—> coagulation bath—> godet—>hot water washing—>acid washing—>water washing—>boiling water drawing—>winding—>drying, and finally rush viscose long fibers are obtained.

[0036] Obtain rush viscose staple fiber by processing in above example 1, carry out following performance analysis:

[0037] 1) Color and cross section

[0038] Such as Figure 4 As shown, the color of the obtained rush viscose fiber retains the color of the rush, and the obtained fiber is green and environmentally friendly, meeting people's pursuit of green life quality. Such as Figure 5 As shown, the cross-sectional structure of the fiber was observed through an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com