Preparation method for adjustable hydrogel-based intelligent fiber responsive to environment temperature

A technology of ambient temperature and hydrogel, applied to the chemical characteristics of fibers, conjugated synthetic polymer artificial filaments, textiles and papermaking, etc., can solve the problems of easy dissociation, high molecular weight requirements, and inability to draw and collect continuously , to improve the structural stability of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

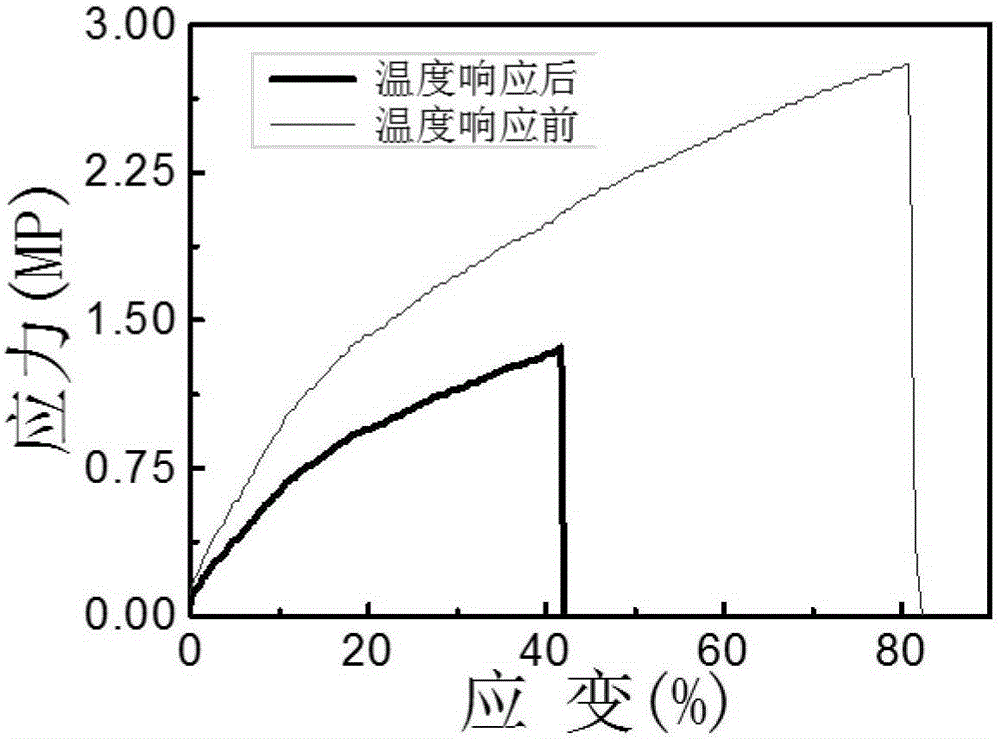

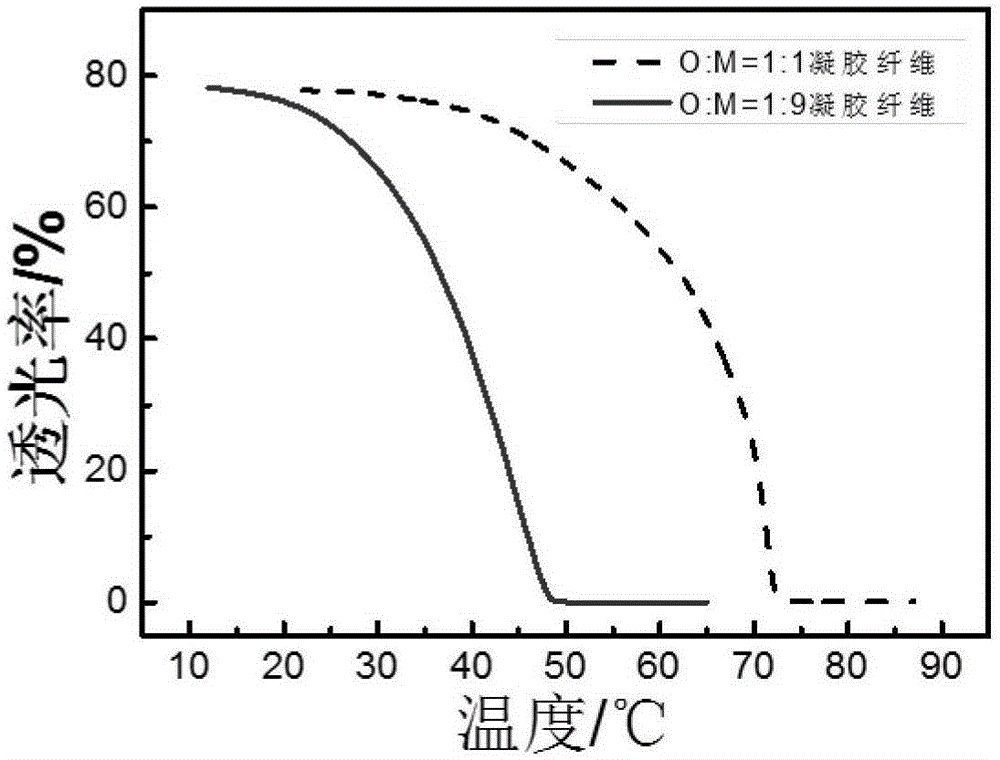

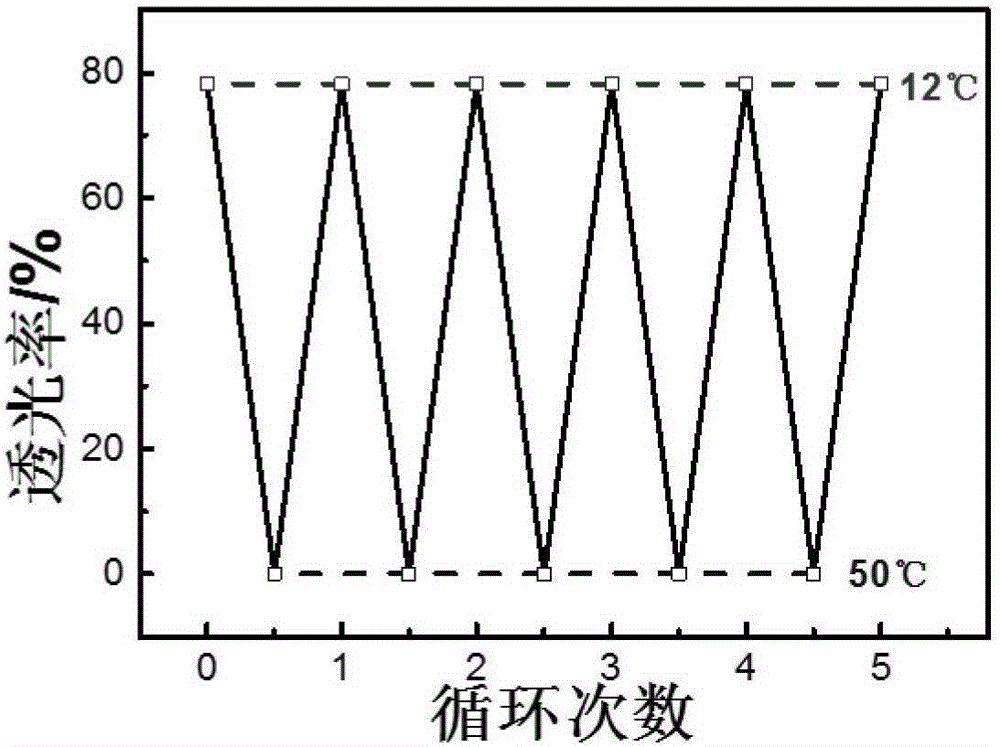

[0033] Weigh 0.5g OMEGA and 0.5g MEO at room temperature 2 Prepare O:M=1:1 solution from MA, and weigh 0.1gOEGMA and 0.9gMEO 2 Prepare O:M=1:9 solution in MA, add 0.005g IRGACURE2959 respectively, and magnetically stir in the dark for 3h until IRGACURE2959 is completely dissolved, and prepare two kinds of POM with different O:M ratios by UV-induced free radical polymerization. Weigh 5g of distilled water at room temperature and add them to the two POMs, stir magnetically for 48 hours until the POMs are completely dissolved, then add 4g PEGDA and 0.02g IRGACURE2959 respectively, and magnetically stir for 3 hours in the dark until the IRGACURE2959 is completely dissolved, then let stand for 6 hours to remove air bubbles, and obtain two spinning solution. The two kinds of spinning liquids were respectively used as spinning nozzles with capillary tubes with an inner diameter of 0.6 mm and a length of 2 cm, and were passed into a deionized water bath by a propulsion pump at a prop...

Embodiment 2

[0038] Weigh 0.6gOEGMA and 1.4gMEO at room temperature 2 MA, 0.01g IRGACURE2959, magnetically stirred in the dark for 3h until IRGACURE2959 was completely dissolved, and POM was prepared by ultraviolet light-induced free radical polymerization. Weigh 5 g of distilled water into POM at room temperature, stir magnetically for 36 hours until POM is completely dissolved, then add 3 g of PEGDA and 0.015 g of IRGACURE2959, and magnetically stir for 3 hours in the dark until IRGACURE2959 is completely dissolved, then let it stand for 6 hours to remove air bubbles and obtain a spinning solution. Use deionized water as the coagulation bath, and a capillary with an inner diameter of 1.5 mm and a length of 2 cm as the spinning nozzle. The spinning solution is passed into the coagulation bath by a propulsion pump at a propulsion rate of 3 ml / h, and the spinning nozzle is immersed in the water bath 1.5 cm below the liquid surface. Set a 60° ultraviolet point light source at a distance of 7...

Embodiment 3

[0040] Weigh 1.25g OEGMA and 1.25g MEO at room temperature 2 MA, 0.0125g IRGACURE2959, magnetically stirred in the dark for 3h until IRGACURE2959 was completely dissolved, and POM was prepared by ultraviolet light-induced free radical polymerization. Weigh 5 g of distilled water and add it to POM at room temperature, stir magnetically for 24 hours until the POM is completely dissolved, then add 2.5 g of PEGDA and 0.0125 g of IRGACURE2959, and magnetically stir for 3 hours in the dark until the IRGACURE2959 is completely dissolved, then let stand for 6 hours to remove air bubbles and obtain a spinning solution. Using deionized water as the coagulation bath, a capillary with an inner diameter of 1.0 mm and a length of 2 cm as the spinning nozzle, the spinning liquid is passed into the coagulation bath by a propulsion pump at a propulsion rate of 10 ml / h, and the spinning nozzle is immersed 2 cm below the surface of the water bath. Set a 90° ultraviolet point light source at a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com