Sliding bar

A sliding rod and rod body technology, which is applied to rotating parts, bearings, screws and other directions that resist centrifugal force, can solve the problems of harsh operating environment of sliding rods, reduce sliding rods, sliding rod corrosion, etc., so as to enhance mechanical properties and improve precipitation strength. words, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

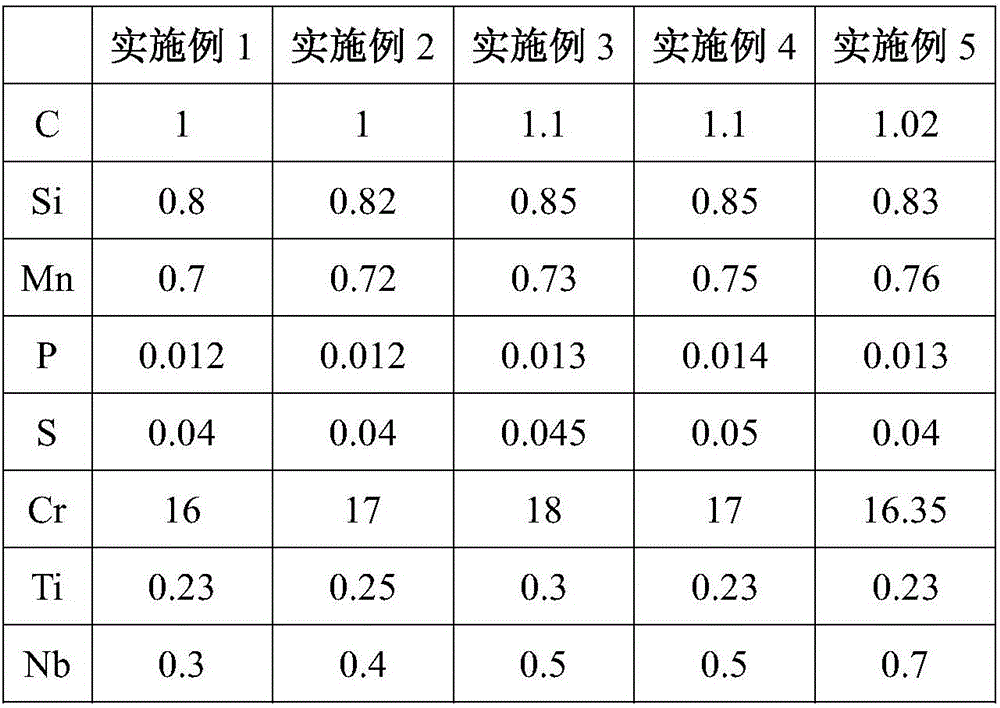

[0045] The composition of this embodiment is the same as that of Example 5, and the difference is that the surface of this embodiment contains a co-infiltration layer, and the co-infiltration process of the co-infiltration layer is:

[0046] First use 1000-mesh sandpaper to polish the surface, then wash it with degreasing agent and water for 10 minutes, and then dry it;

[0047] Seal the dried sliding rod and co-infiltration agent together into the infiltration tank, put it into a heating furnace, raise the temperature to 950°C, and co-infiltrate for 4 hours.

[0048] The co-penetrating agent is a mixture of ferroboron and ferrotitanium.

Embodiment 7

[0050] The difference between this embodiment and Embodiment 6 is that the co-infiltration agent also includes a chromium donor, and the chromium donor is ferrochrome.

Embodiment 8

[0052] The difference between this embodiment and embodiment 7 is that the co-penetration agent also includes the activator potassium fluoroborate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap