Furnace core coil type high-medium-low frequency smelting furnace

A smelting furnace and furnace core technology, which is applied to furnaces, crucible furnaces, furnace types, etc., can solve the problems that the volume of the smelting furnace cannot be too large, the smelting loss is large, and the heating temperature is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

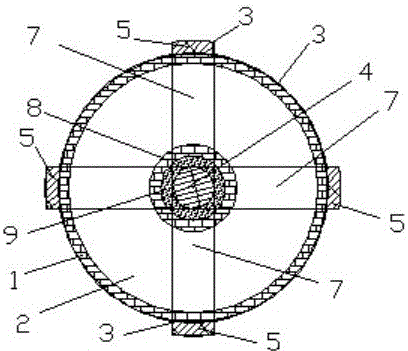

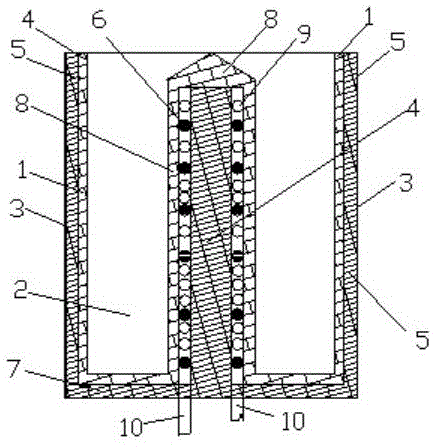

[0013] 1) Make a cross or spoke-shaped iron core (7) in the bottom of the melting furnace in the furnace shell, fix a square or round iron core (4) in the middle, and the height of the iron core should not exceed the melting furnace mouth, and design the iron core according to the needs of smelting high;

[0014] 2) Set the cooling water coil and the water supply coil coil outside the center iron core, and the cooling water of the furnace core power supply coil and the power supply interface of the water cable are drawn out at the bottom of the furnace;

[0015] 3) The furnace shell is designed with a furnace shell iron core in the furnace shell corresponding to the furnace bottom conductive core, and the furnace shell magnetic core reaches the height of the furnace mouth;

[0016] 5) Insulate and insulate the inner side of the furnace shell, the bottom of the furnace, the power supply coil of the furnace core and the outer side of the independent iron core. The insulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com