Fire coal combustion source discharged carbonyl compound sampling device

A carbonyl compound and sampling device technology, which is applied in sampling devices, measuring devices, sampling, etc., can solve the problems of carbonyl compound detection results, high pollutant concentration, and unsatisfactory problems, so as to reduce deviation, uniform dilution process, and convenient The effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

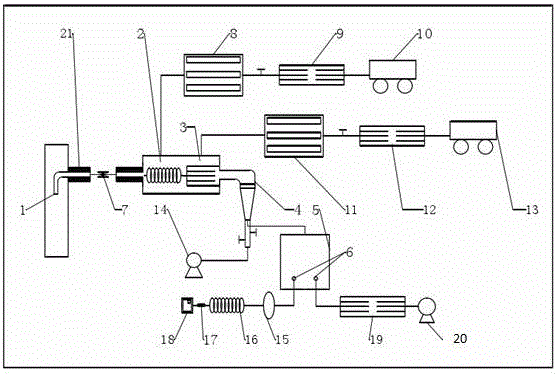

[0025] In this example, see figure 1 , a carbonyl compound sampling device emitted from a coal-fired combustion source, consisting of a constant-velocity sampling head 1, an intake pipe 21, a venturi tube 7, a cascaded flue gas dilution system, a residence chamber 5, and a carbonyl compound sampling system connected in sequence to form a fluid In the sample delivery pipeline, one end of the isokinetic sampling head 1 is inserted into the chimney for raw flue gas collection, and the other end of the isokinetic sampling head 1 is connected to the venturi tube 7 through the inlet pipe 21, and the cascaded flue gas dilution system consists of one stage The dilution system 2 and the secondary dilution system 3 are connected, the Venturi tube 7 is connected to the inlet of the primary dilution system 2, and the primary dilution system 2 is sequentially connected to the first air preheater 8, the first air cleaner 9 and the first Air compressor 10, the air is transported by the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com