Automatic control type circulating water tank for simulating instantaneous dam break

A technology of circulating water tank and circulating water pump, which is applied in the direction of educational appliances, teaching models, instruments, etc., can solve the problems of affecting the flow state, time-consuming, and difficult to accurately control the opening speed of the gate, so as to achieve high accuracy and improve experimental efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

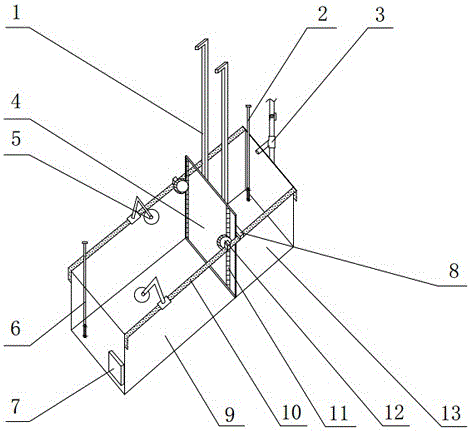

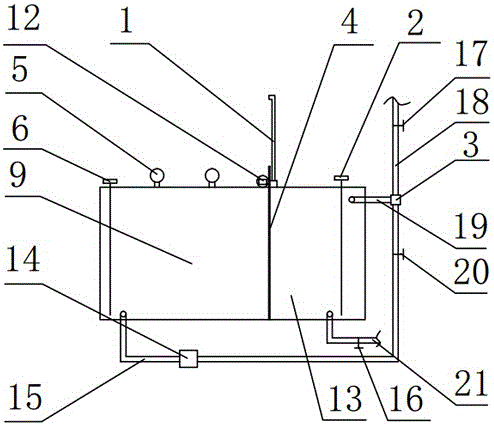

[0030] Such as figure 1 As shown, the present invention includes a water tank, a gate, a water level control system and a gate lifting control system, wherein the water tank is divided into two parts by the gate door plate 4, which are respectively a water tank 13 upstream of the gate and a water tank 9 downstream of the gate, and the upper edge of the water tank in the length direction of the water tank is fixed. A pair of guide rails 10 along the upper edge of the water tank are provided. Such as figure 2As shown, the water level control system of the present invention includes a water injection pipe 18, a water inlet pipe 19, a water guide pipe 15 and an industrial control computer 7 connected by a three-way pipe fitting 3, wherein the water injection pipe 18 is provided with a first electromagnetic valve 17, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com