Same-side interconnected solar cell string, preparation method thereof, solar cell assembly and solar cell system

A solar cell and module technology, applied in the field of solar cells, can solve the problems of not too thick ribbon, power density drop, high ohmic loss, etc., and achieve the effects of avoiding ribbon desoldering, reducing spacing, and improving fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

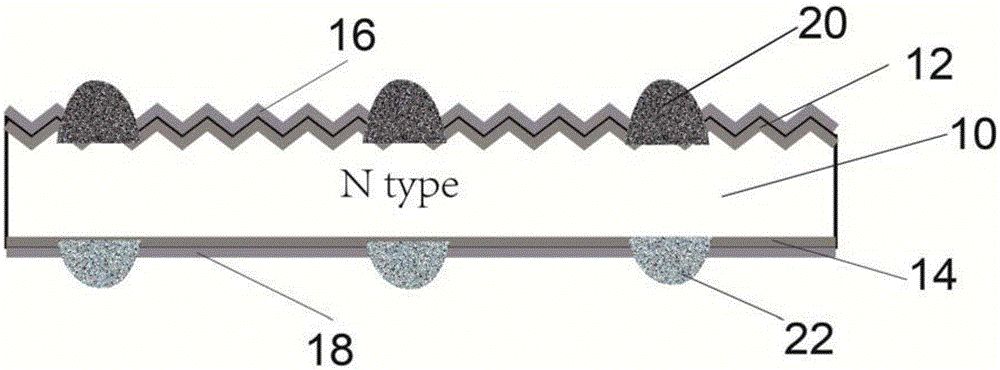

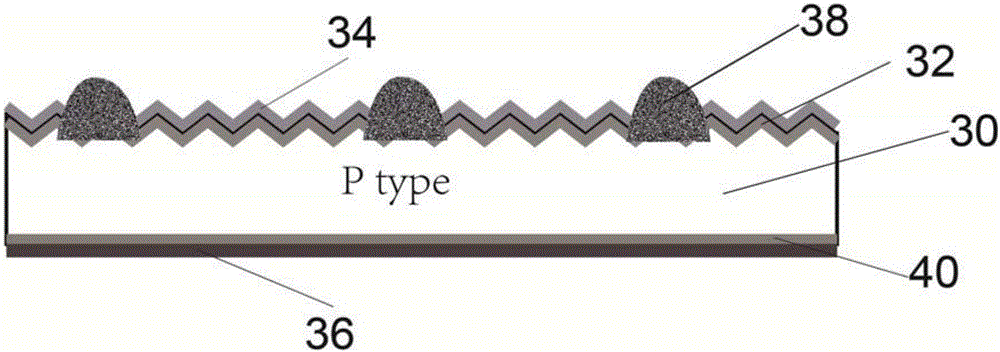

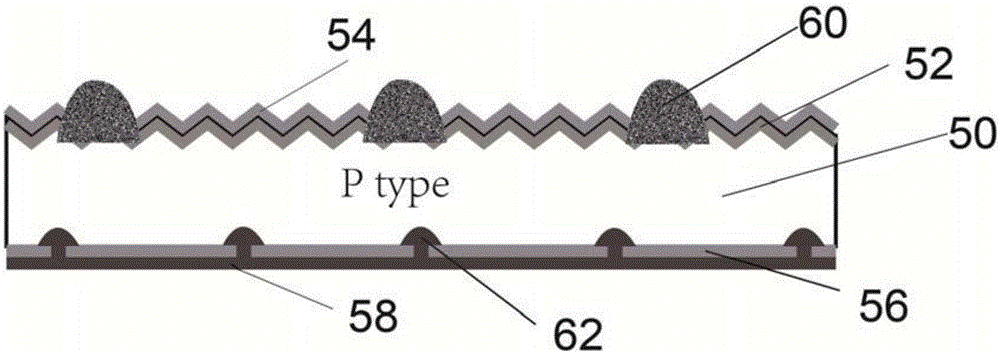

[0028] A same-side interconnected solar cell string provided in this embodiment includes N-type crystalline silicon solar cells and P-type crystalline silicon solar cells, and the N-type crystalline silicon solar cells and P-type crystalline silicon solar cells are arranged alternately. N-type crystalline silicon solar cells and P-type crystalline silicon solar cells are interconnected on the same side through conductive strips; the interval between N-type crystalline silicon solar cells and P-type crystalline silicon solar cells is 0.05-0.19mm; preferably, the conductive strips are tin Copper-wrapped welding strip, the width of the welding strip is 0.5-2mm, and the thickness of the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com