Vinylcyclopropane, monomer composition, polymer, polymer composition, and article

A technology of vinylcyclopropane and monomer composition, applied in the field of polymer composition, can solve problems such as compounds that have not yet been developed, and achieve the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0157]

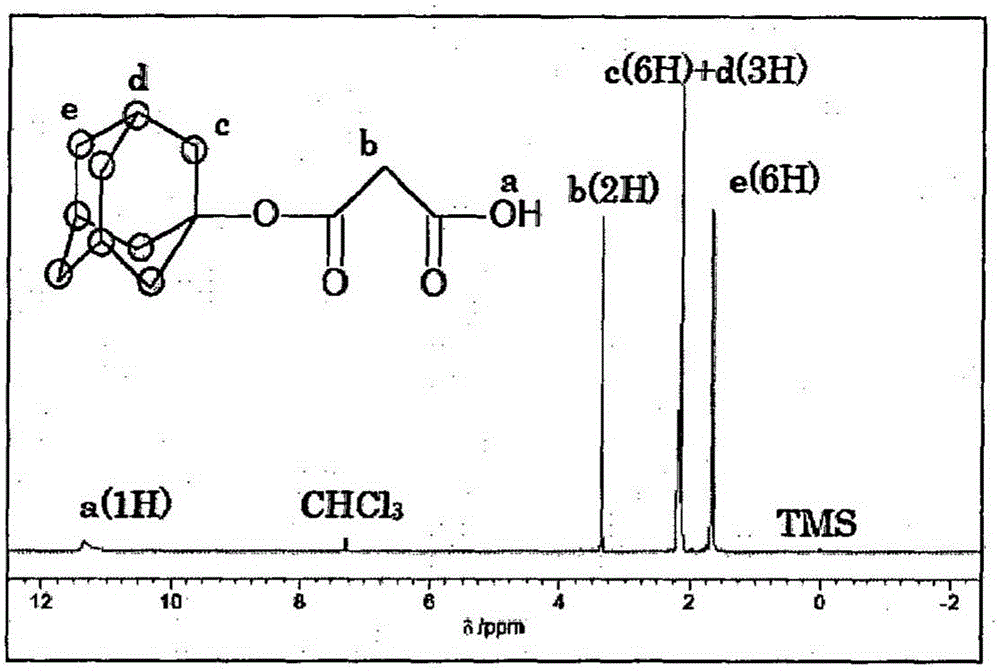

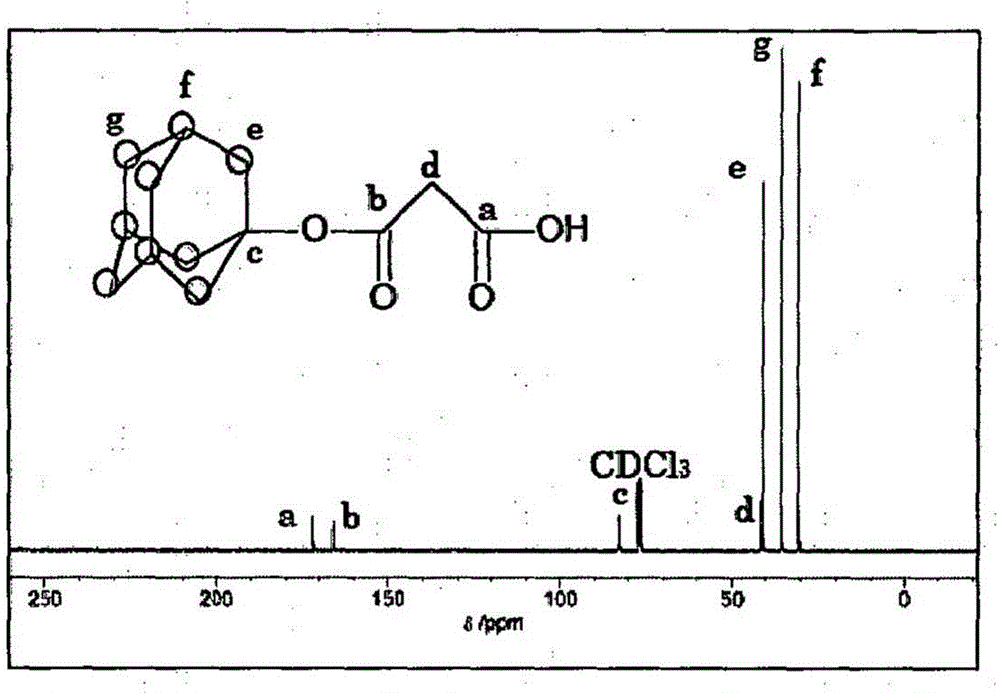

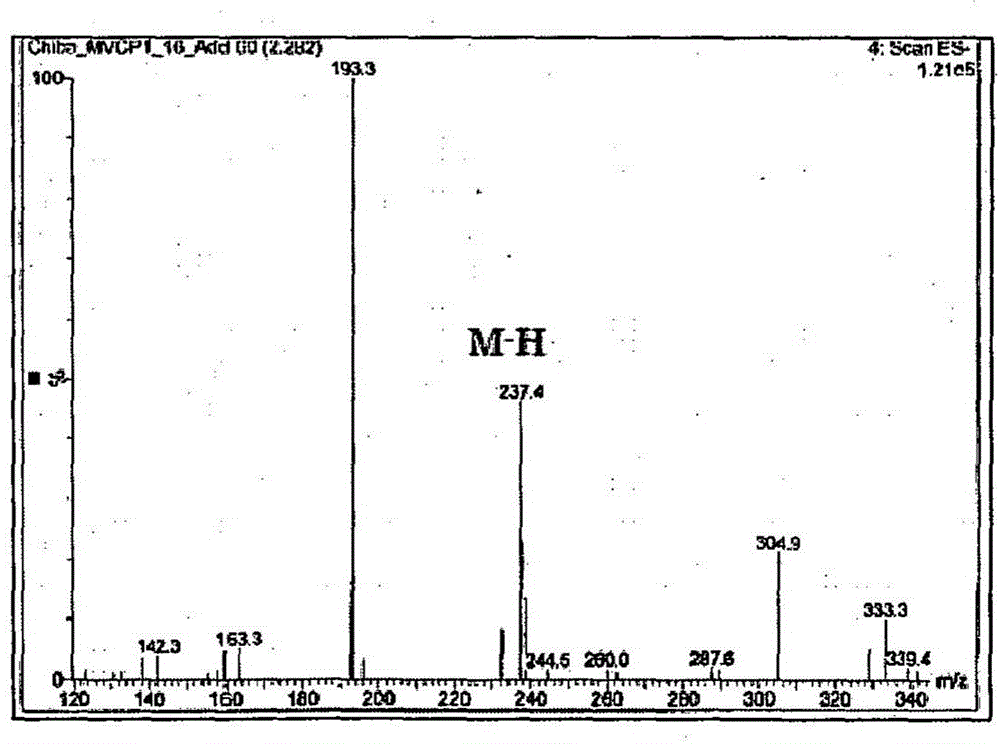

[0158] As shown in the following reaction scheme, the compound represented by the following structural formula (6) is produced through the first-stage reaction, the second-stage reaction, and the third-stage reaction.

[0159] [Chemical formula 9]

[0160]

[0161] >

[0162] [Chemical formula 10]

[0163]

[0164] Hereinafter, the first-stage reaction, the second-stage reaction, and the third-stage reaction will be explained.

[0165] >

[0166] Use a heat gun to heat the Dai's condenser tube equipped with a three-way stopcock on the main pipe, seal the side tube with a rubber septum cap, and heat a two-necked flask (100 mL) with a stir bar inside, and degas and dry it with a vacuum pump , So that the water attached to the surface of the appliance is completely removed. After that, a gas collection bag (or balloon) filled with nitrogen was connected to the three-way cock, and nitrogen was introduced into the reactor. After that, 9.14 g (60 mmol) of 1-adamantanol and 8.65 g (...

Embodiment 2

[0211] In Example 1, equal amounts (mmol) of Ad-MVCP and tricyclodecane dimethanol dimethacrylate (DCP) were used (manufacturing company name: Shin Nakamura Chemical Industry Co., Ltd., trade name: NK ester DCP) These two types of monomers replace the synthesized (1,3-bis[(1-adamantyloxycarbonyl-2-vinylcyclopropane-1-yl)carbonyloxy]adamantane (Ad- MVCP), except for this, it was performed in the same manner as in Example 1, and (i) the volume change during polymerization was evaluated. The evaluation results are shown in Table 2 below.

[0212] It should be noted that in Example 2, 0.159 g (0.479 mmol) of DCP, 0.341 g (0.479 mmol) of Ad-MVCP, 0.2 mL of toluene (dehydrated) and a stir bar were added to the ampoule tube, and heated at 70°C , Stir to make it uniform. After cooling to room temperature, the diluted AIBN solution (6.3 mg (0.038 mmol) of AIBN dissolved in 0.28 mL of toluene (dehydration)) was added to the ampoule tube, and after freezing and degassing, the ampoule tube ...

Embodiment 3

[0217] In Example 2, the monomer ratio of DCP and Ad-MVCP was set to 1:2 instead of using the same amount of monomers of DCP and Ad-MVCP. Except for this, it was performed in the same manner as in Example 2. Evaluation (i ) Volume change during polymerization. The evaluation results are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| volume change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com