Curved Fresnel lens condensation and facility agriculture combined solar heat collecting system

A technology of solar heat collection and facility agriculture, which is applied in the fields of solar heat collection and agricultural facilities, can solve the problems of affecting the lighting of greenhouses, increasing the distance between greenhouses, and affecting the collection of sunlight in greenhouses, so as to save space and solar resources, and realize agricultural production. The effect of light complementation and avoiding shading phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

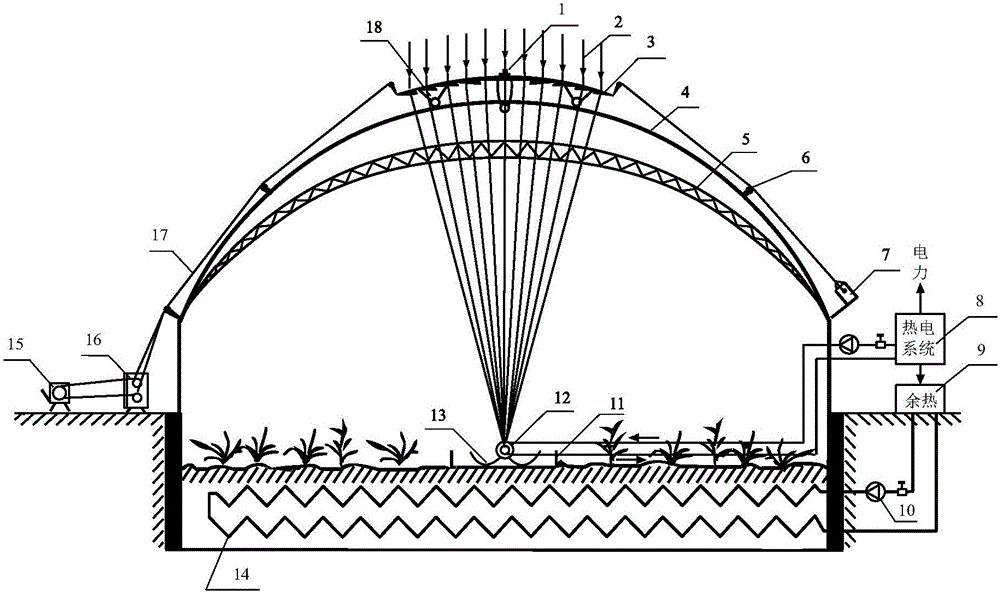

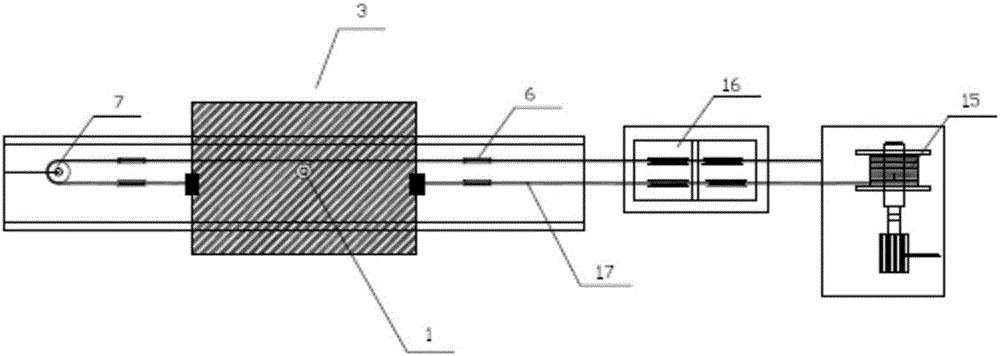

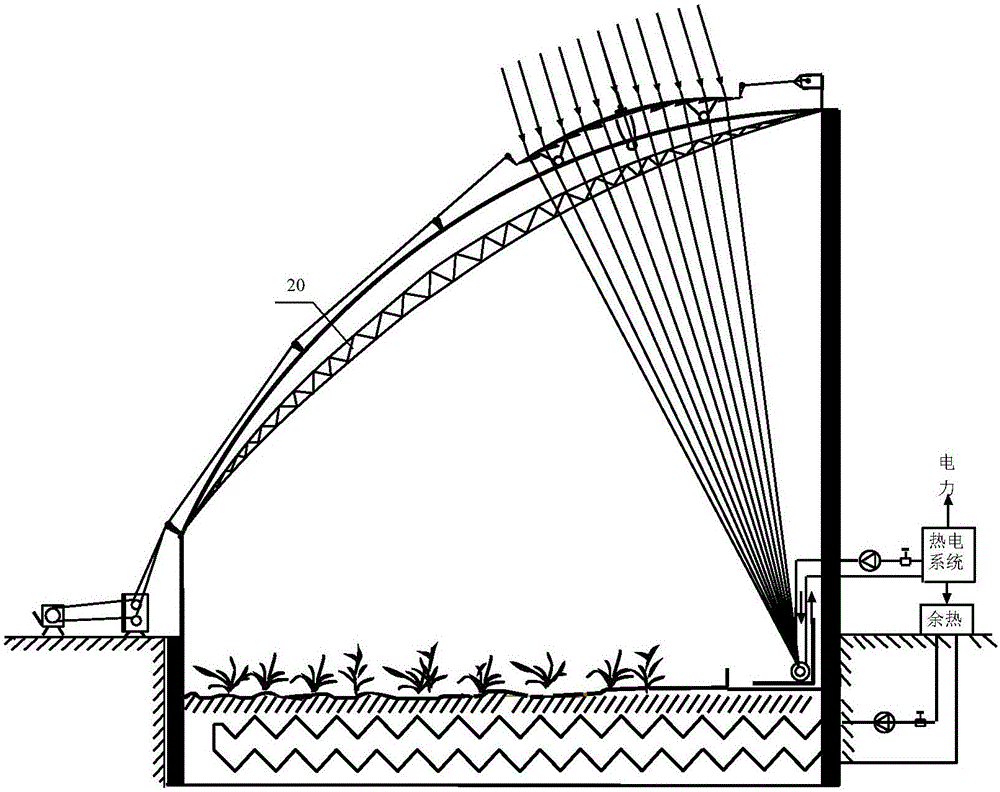

[0016] figure 1 It is the operating principle diagram of the system of the present invention. exist figure 1 In the above, the operating principle of the device can be explained step by step as follows: the solar greenhouse is built along the north-south direction, the curved Fresnel transmission concentrator (3) is fixedly connected with the roller (18) through the support shaft seat, and is erected on the On the track (4) above the greenhouse vault (5), the solar tracker (1) installed on the center line of the outer surface of the concentrator (3) provides accurate position information for it, and the wire rope of the traction system ( 17) do circular motion on the track (4) under the traction. The vacuum tube receiver (12) is placed inside the greenhouse and at the center of the track (4), and a safety isolatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com