Novel Hy-Vo tooth-shaped chain assembly technology

An assembly process and technology of toothed chains, applied in metal chains, transportation and packaging, motor vehicles, etc., can solve the problems of low production efficiency, unsuitable for Hy-Vo toothed chain assembly production, high scrap rate, etc., and achieve extended use Longer life, better wetting, better wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

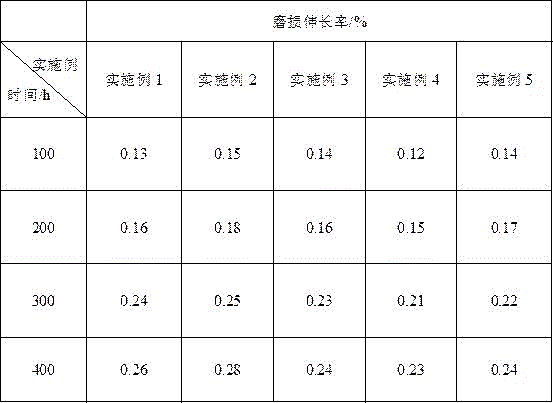

Examples

Embodiment 1

[0016] An assembly process of a novel Hy-Vo toothed chain, comprising the following process steps:

[0017] (1) Put the guide plate on the pin shaft so that it is located at the center of the pin shaft, and put a number of equal number of inner chain plates on both sides of the guide plate. The thickness ratio of the guide plate to the inner chain plate is 1:1.2, where the guide plate, the inner chain plate and the pin shaft all adopt clearance fit;

[0018] (2) After the inner chain plate is assembled in step (1), use a pressing machine to install the outer chain plate on both ends of the pin shaft, wherein the outer chain plate and the pin shaft adopt interference fit, and the assembly of the outer chain plate The specific method is: first heat the outer chain plate to 225°C, then place it on the end of the pin shaft on the pressing machine, use the pressure of the pressing machine to press it into the pin shaft and fix it, and then cool it naturally after pressing to room ...

Embodiment 2

[0023] An assembly process of a novel Hy-Vo toothed chain, comprising the following process steps:

[0024] (1) Put the guide plate on the pin shaft so that it is located at the center of the pin shaft, and put a number of equal number of inner chain plates on both sides of the guide plate. The thickness ratio of the guide plate to the inner chain plate is 1: 1.3, where the guide plate, the inner chain plate and the pin shaft all adopt clearance fit;

[0025] (2) After the inner chain plate is assembled in step (1), use a pressing machine to install the outer chain plate on both ends of the pin shaft, wherein the outer chain plate and the pin shaft adopt interference fit, and the assembly of the outer chain plate The specific method is: first heat the outer chain plate to 226°C, then place it on the end of the pin shaft on the pressing machine, use the pressure of the pressing machine to press it into the pin shaft and fix it, and then cool it naturally after pressing to room...

Embodiment 3

[0030] An assembly process of a novel Hy-Vo toothed chain, comprising the following process steps:

[0031] (1) Put the guide plate on the pin shaft so that it is located at the center of the pin shaft, and put a number of equal number of inner chain plates on both sides of the guide plate. The thickness ratio of the guide plate to the inner chain plate is 1: 1.4, where the guide plate, the inner chain plate and the pin shaft all adopt clearance fit;

[0032] (2) After the inner chain plate is assembled in step (1), use a pressing machine to install the outer chain plate on both ends of the pin shaft, wherein the outer chain plate and the pin shaft adopt interference fit, and the assembly of the outer chain plate The specific method is: first heat the outer chain plate to 248°C, then place it on the end of the pin shaft on the pressing machine, use the pressure of the pressing machine to press it into the pin shaft and fix it, and then cool it naturally after pressing to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com