Inorganic material and wooden decorative metal composite board structure

A technology of inorganic materials and inorganic material layers, applied in the direction of metal layered products, wood layered products, building structures, etc., can solve the problems of beautiful appearance, incomplete plane connection, and easy to be damp, so as to improve fire resistance, The effect of connecting beautifully and improving the aesthetically pleasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

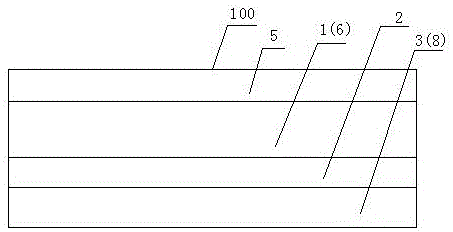

[0041] Such as figure 1 As shown, in this example, the board body 100 includes a flame retardant layer 5, a wood veneer layer 1 or a printing paper layer 6, a metal layer 2, and a non-woven fabric layer 3 or a waterproof kraft paper layer 8 arranged sequentially from top to bottom. The fuel layer 5 has a thickness of 0.01-0.05mm, the wood veneer layer 1 or printing paper layer 6 has a thickness of 0.15-3mm, the metal layer 2 has a thickness of 0.03-3mm, and the non-woven fabric layer 3 or waterproof kraft paper layer The thickness of 8 is 0.01-0.2mm, the flame retardant layer 5, the veneer layer 1 or the printing paper layer 6, the metal layer 2 and the non-woven fabric layer 3 or the waterproof kraft paper 8 layers are bonded and compounded by the polymer adhesive, and the veneer is passed through Flame retardant treatment, wood-decorated metal panels have fire-proof and moisture-proof functions. The three-in-one structure of this embodiment is suitable for wall and ceiling ...

Embodiment 2

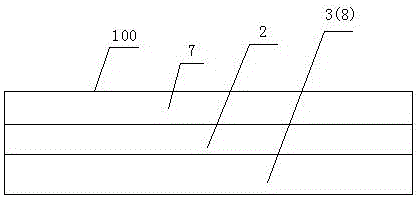

[0043] Such as figure 2As shown, in this embodiment, the plate body 100 includes a metal thermal transfer layer 7, a metal layer 2, a non-woven fabric layer 3 or a waterproof kraft paper layer 8 arranged sequentially from top to bottom, and the metal thermal transfer layer 7 The thickness is 0.01-0.1mm, the thickness of the above-mentioned metal layer 2 is 0.03-3mm, the thickness of the above-mentioned non-woven fabric layer 3 or waterproof kraft paper layer 8 is 0.01-0.2mm, the metal thermal transfer layer 7, the metal layer 2 and the non-woven After the cloth layer 3 or the waterproof kraft paper layer 8 is bonded and compounded by a polymer adhesive, various patterns are thermally transferred on the metal thermal transfer layer 7 to improve the appearance of the composite board structure. This embodiment is suitable for furniture boards , ceilings, wall panels and other decorative surfaces.

Embodiment 3

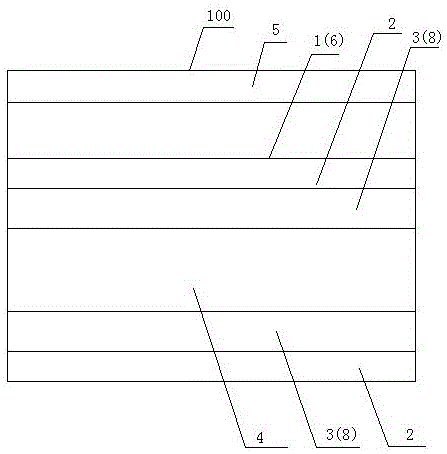

[0045] Such as image 3 As shown, in this embodiment, the board body 100 includes a flame retardant layer 5, a wood veneer layer 1 or a printing paper layer 6, a metal layer 2, a non-woven fabric layer 3 or a waterproof kraft paper layer 8, which are sequentially arranged from top to bottom. Inorganic material layer 4, non-woven fabric layer 3 or waterproof kraft paper layer 8 and metal layer 2, the thickness of the above-mentioned flame retardant layer 5 is 0.01-0.05mm, the thickness of the above-mentioned wood veneer layer 1 or printing paper layer 6 is 0.15-3mm, The metal layer 2 has a thickness of 0.03-3 mm, the non-woven fabric layer 3 or waterproof kraft paper layer 8 has a thickness of 0.01-0.2 mm, and the inorganic material layer 4 has a thickness of 3-30 mm. This embodiment is suitable for ceiling and wall panels and furniture panel upholstery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com