Thermal-band type bubbling hood aluminum coated at fixed point and preparation technology of thermal-band type bubbling hood aluminum

A tropical-type blister aluminum and preparation process technology, which is applied to the device, coating, flexible covering and other directions of coating liquid on the surface, can solve the problems of the reduction of heat sealing strength, etc., and achieves reduced emission and low implementation cost. , the effect of stability and heat seal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

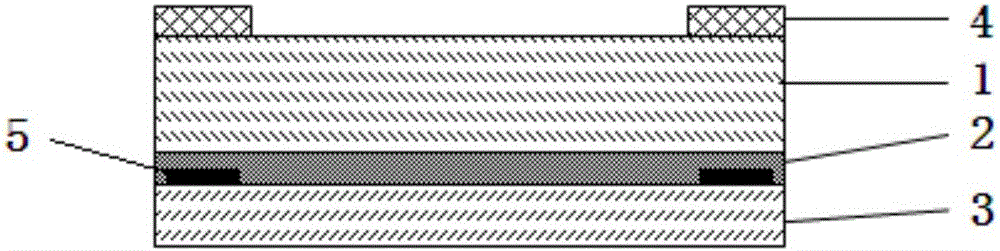

[0028] Such as figure 1 As shown, this case lists an embodiment of fixed-point coating of hot-tropical blister aluminum, which includes: an aluminum foil layer 1, the aluminum foil layer 1 has a first surface and a second surface opposite, and the first surface is provided with polyurethane adhesive An agent layer 2, the surface of the polyurethane adhesive layer 2 is provided with a polyamide layer 3 or a polyester layer 3; the second surface is provided with a fixed-point coated VC adhesive layer 4; wherein, the polyurethane adhesive layer and the polyamide layer Or an ink printing block 5 is also arranged between the polyester layers. The effect of the ink printing block 5 is to be beneficial to carry out photoelectric tracking in the charging link.

[0029] In the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com