Method for refining trelagliptin succinate

A technology of trelagliptin succinate and a purification method, applied in the field of pharmacy, can solve the problems of low purity of trelagliptin succinate, being difficult to be applied in industrial production, difficult to remove residual solvent, etc., achieving easy control of solvent residue, The effect of producing green environmental protection and improving drug safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

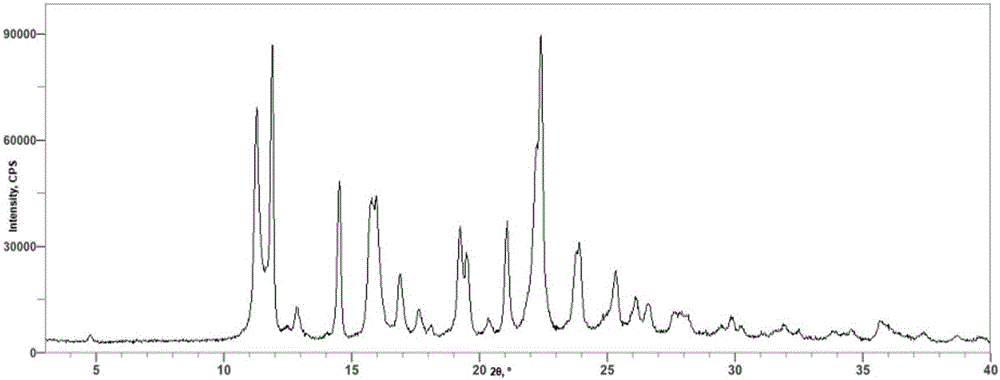

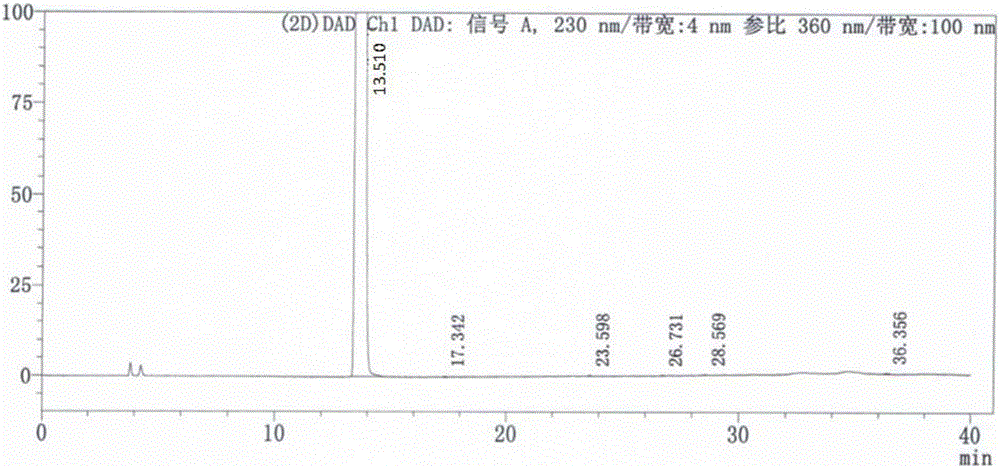

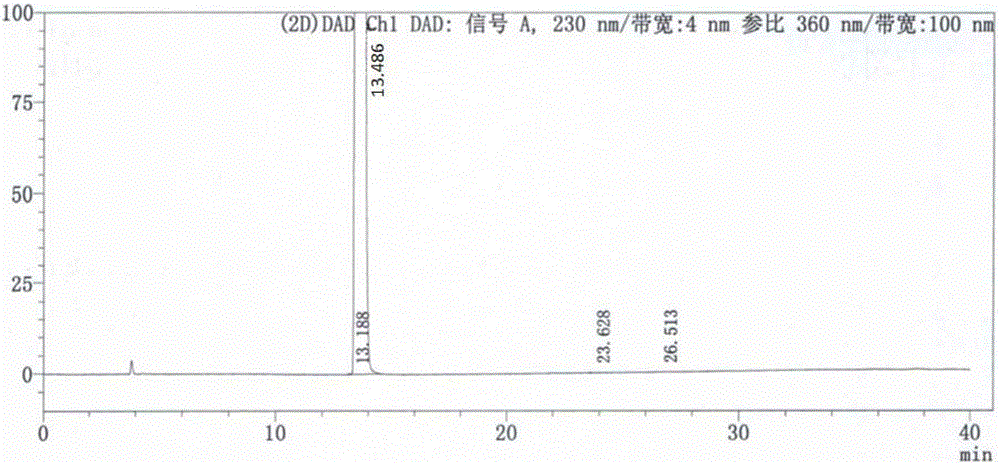

Image

Examples

Embodiment 1

[0039] The refining method of the trexagliptin succinate provided by the present embodiment comprises:

[0040] Heat 800mL of a mixed solution of water and methanol mixed at a volume ratio of 1:5 to 50°C, then mix with 100g of trexagliptin succinate, and stir until clear to obtain a trexagliptin succinate solution.

[0041] Then, the temperature of the succinate trexagliptin solution was lowered to 2°C, and after crystallization, it was filtered, and the filter cake was washed with methanol and dried to obtain a white solid, that is, refined succinate trexagliptin.

Embodiment 2

[0043] The refining method of the trexagliptin succinate provided by the present embodiment comprises:

[0044] First, prepare 1000 mL of a mixed solution of water and acetone at a volume ratio of 1:9, then add 100 g of trexagliptin succinate to the mixed solution, heat to 55°C and stir until clear to obtain a trexagliptin succinate solution.

[0045] Then place the succinate trexagliptin solution in a fume hood, stir and crystallize for 60 minutes, filter, and wash the filter cake with acetone, then dry it under normal pressure at 50°C for 10 hours to obtain a white solid, that is, refined amber Trexagliptin.

Embodiment 3

[0047] The refining method of the trexagliptin succinate provided by the present embodiment comprises:

[0048] Heat 1000mL of a mixed solution of water and ethanol at a volume ratio of 1:10 to 60°C, then mix it with 100g of trexagliptin succinate, and stir until clear to obtain a trexagliptin succinate solution.

[0049] Then reduce the temperature of the succinate solution to 2°C, crystallize for 60 minutes, filter, and wash the filter cake with ethanol, and then dry it under normal pressure at 55°C for 8 hours to obtain a white solid, that is, refined amber Trexagliptin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com