A plug and a halogen-free flame-retardant material for the plug

A plug and polypropylene technology, applied in the field of flame retardant materials, can solve environmental hazards and other problems, and achieve the effects of reducing usage, good high temperature resistance, and no dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

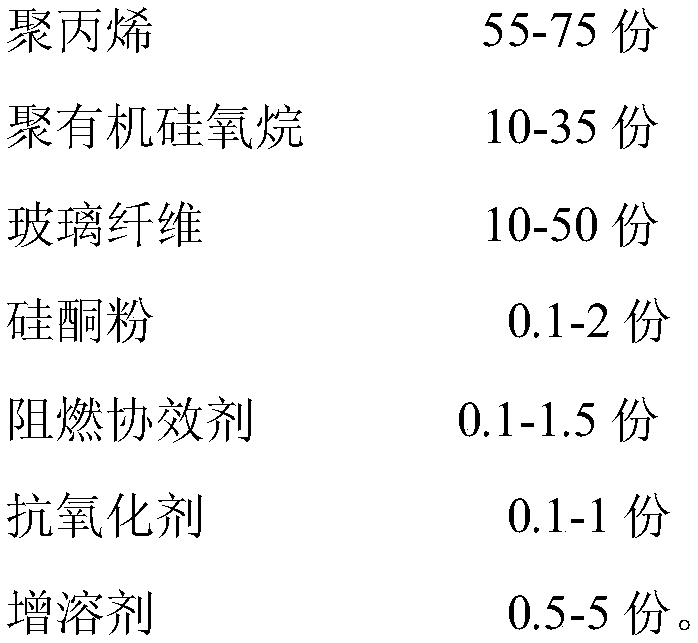

Method used

Image

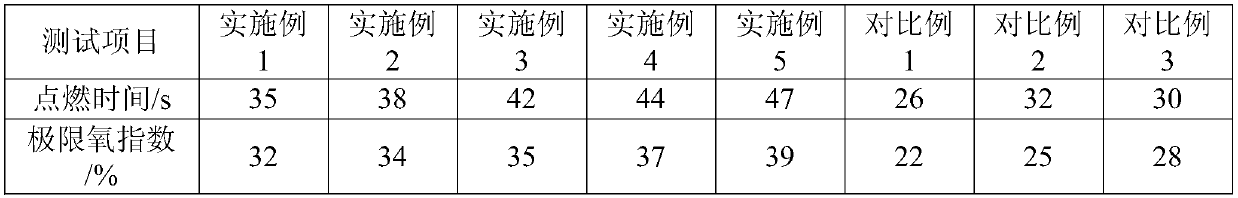

Examples

Embodiment 1

[0034] Step 1: Weigh 60 parts by weight of polypropylene and 10 parts by weight of polyorganophenylene siloxane into a high-speed mixer for mixing, stir at high speed for 5 minutes, and then weigh 0.1 parts by weight of silicone powder, parts by weight are 0.1 parts of nano-montmorillonite, parts by weight are 0.1 parts of 2,6-di-tert-butyl-4-aminophenol, parts by weight are three (2,4-di-tert-butylbenzene Base) phosphite, add in the high mixer and continue to mix, stir for 3min, finally weigh 0.5 parts by weight of maleic anhydride grafted ethylene-vinyl acetate copolymer into the high mixer, stir for 1min, discharge for later use ;

[0035] Step 2: Dry the mixed material obtained in step 1 in a hot air hopper for 3 hours;

[0036] Step 3: adding the dried mixed material in step 2 and 10 parts by weight of glass fiber to a twin-screw extruder for extrusion and granulation, and the frequency of the extruder is 400 rpm;

[0037] Step 4: Place the plug core on the mold, inject...

Embodiment 2

[0039] Step 1: Weigh 62 parts by weight of polypropylene and 12 parts by weight of polyorganophenylene siloxane into a high mixer and mix them at high speed for 5.5 minutes, then weigh 0.4 parts by weight of silicon Ketone powder, 0.4 parts by weight of nano-montmorillonite, 0.3 parts by weight of 2,6-di-tert-butyl-4-aminophenol, 0.4 parts by weight of three (2,4-di-tert-butyl Phenyl) phosphite, add in the high mixer and continue mixing, stir for 3.5min, finally take by weight the maleic anhydride grafted ethylene-vinyl acetate interpolymer of 0.8 parts and add in the high mixer, stir for 1.21min, Discharge spare;

[0040] Step 2: Dry the mixed material obtained in step 1 in a hot air hopper for 3.2 hours;

[0041] Step 3: adding the dried mixed material in step 2 and 15 parts by weight of glass fiber into a twin-screw extruder to extrude and pelletize, and the frequency of the extruder is 450 rpm;

[0042] Step 4: Place the plug core on the mold, inject the product obtained i...

Embodiment 3

[0044] Step 1: Weigh 65 parts by weight of polypropylene and 15 parts by weight of polyorganophenylene siloxane into a high-speed mixer for mixing, stir at high speed for 6 minutes, and then weigh 0.5 parts by weight of silicone powder, parts by weight are 0.6 parts of nano-montmorillonite, parts by weight are 0.6 parts of 2,6-di-tert-butyl-4-aminophenol, parts by weight are three (2,4-di-tert-butylbenzene Base) phosphite, add in the high mixer and continue to mix, stir for 4min, finally weigh 1 part of maleic anhydride grafted ethylene-vinyl acetate interpolymer into the high mixer, stir for 1.5min, discharge spare;

[0045] Step 2: Dry the mixed material obtained in step 1 in a hot air hopper for 3.5 hours;

[0046] Step 3: adding the dried mixed material in step 2 and 20 parts by weight of glass fiber into a twin-screw extruder to extrude and pelletize, and the frequency of the extruder is 500 rpm;

[0047] Step 4: Place the plug core on the mold, inject the product obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com