Pre-treatment method capable of improving anaerobic digestion biogas production efficiency of gramineous plants

A technology of gramineous plants and anaerobic digestion, which is applied in the field of improving the efficiency of anaerobic digestion of gramineous plant straws to produce gas, can solve the problems of extensive and single pretreatment methods, shorten the anaerobic digestion cycle, optimize utilization, and reduce economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

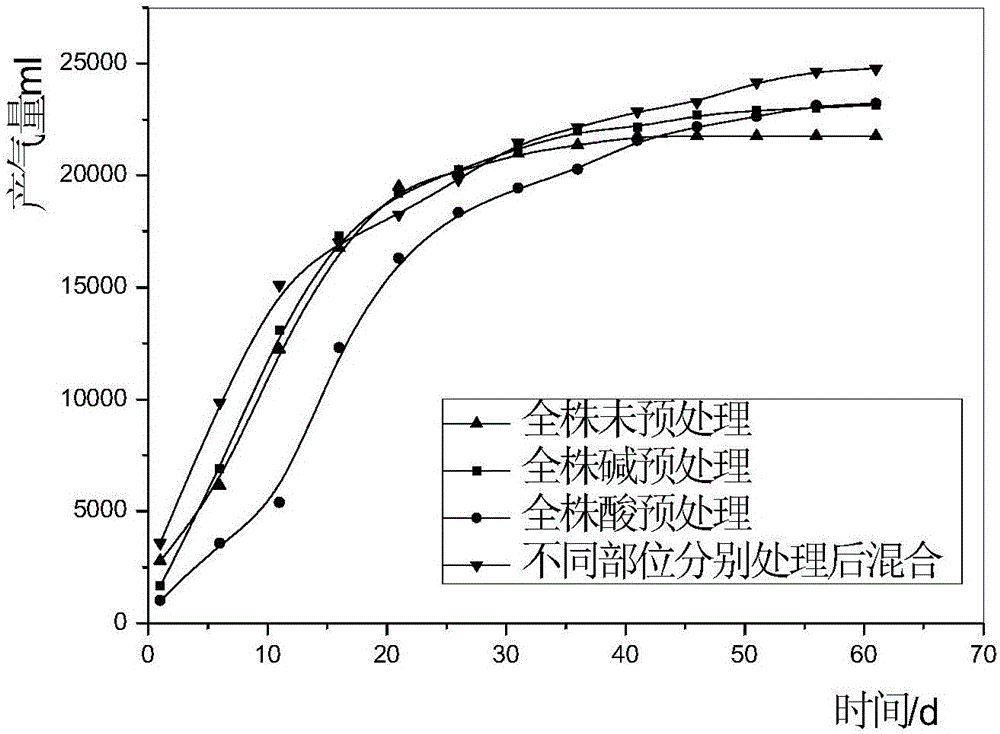

[0026] In this embodiment, corn stalks are used as the treatment object, and the method of the present invention is used to pretreat the stalks, and a control experiment is carried out at the same time, and an anaerobic digestion experiment is carried out after the pretreatment:

[0027] 1. The complete corn stalks of 10 plants were selected to be air-dried naturally, then manually peeled off, sorted into four parts: leaves, stem bark, stem pith, and corn cobs, and crushed through a 40-mesh sieve with the whole plant control sample;

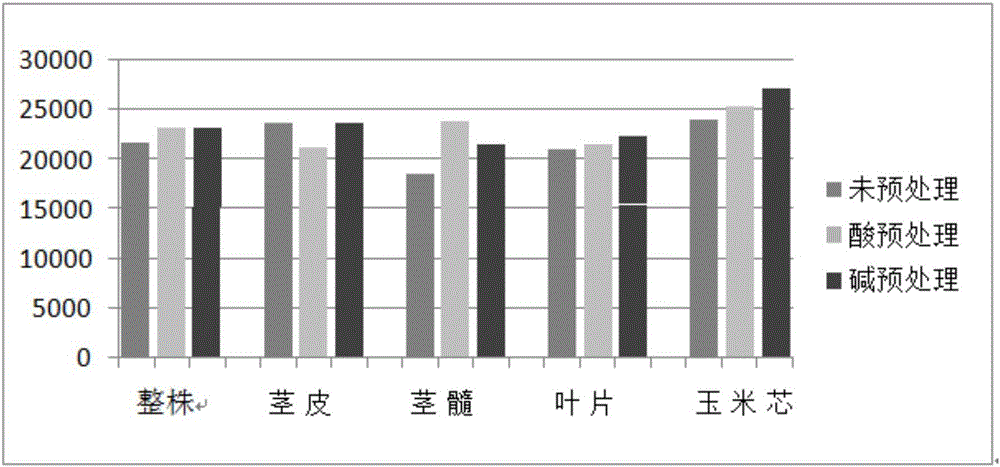

[0028] 2. Weigh the raw materials of each part of corn stalk respectively: 37.68g of stem bark, 38.65g of stem pith, 36.47g of leaves, 36.42g of corncobs, 36.96g of whole plant (both contain the same dry matter quality: 34.78g) in three parts each, Put it in a jar, and carry out three experimental groups: no treatment, 10% dilute hydrochloric acid immersion treatment and 10% ammonia water immersion treatment respectively. The solid-liquid ratio of...

Embodiment 2

[0039] Different parts of sorghum stalks were mechanically crushed and sieved in the same manner as in Example 1. Then the stem pith of the sorghum straw is treated with sulfuric acid, the leaves and the rest of the straw are treated with sodium hydroxide, and the stem bark is not treated. Anaerobic fermentation was performed after pretreatment, and compared with the anaerobic digestion of the whole plant without pretreatment, and the biogas production of anaerobic digestion after pretreatment of the whole plant with sulfuric acid and sodium hydroxide pretreatment.

[0040] The results show that, similar to the results shown in Example 1, after pretreatment of each part, anaerobic fermentation is performed to produce biogas, the biogas production is greatly increased, the fermentation cycle is shortened, and the economic benefit is obviously improved.

[0041] It should be noted that in the present invention, the acid treatment is exemplified by hydrochloric acid and sulfuric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com