A kind of manufacturing method of waterproof coating cloth

A manufacturing method and technology of coating cloth, applied in coating, textile and papermaking, textile and other directions, can solve the problems of substandard environmental protection, substandard mechanical properties, insufficient anti-seepage ability, etc., and achieve a strong market and vitality, defects Less, dense and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A kind of manufacture method of anti-seepage coating cloth.

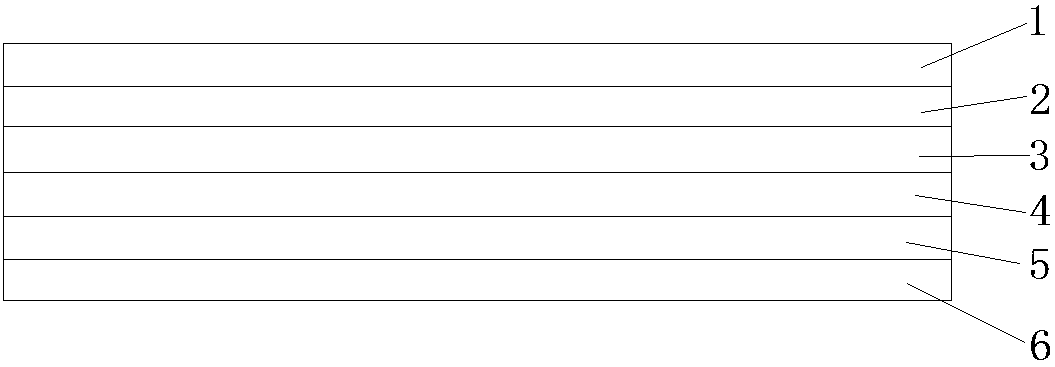

[0041] The impermeable coating cloth such as figure 1 As shown, it consists of protective layer A1, internal reinforcement layer 2, bonding layer A3, base fabric 4, bonding layer B5, and protective layer B6 from top to bottom, wherein protective layer A1 is coating agent A, and internal reinforcement layer 2 is coating Layer agent B, bonding layer A3 are crosslinking coating agent B, bonding layer B5 are crosslinking coating agent B, protective layer B6 coating agent A; Its manufacture comprises the following steps:

[0042] (1) High-strength and low-shrinkage polyester yarns are used as raw materials, with a denier of 1000D, manufactured on a high-speed rapier loom with the Panama weave method, and the weaving density is 15×15 / inch, and the grammage is 267g / m 2 High-strength polyester base fabric;

[0043] (2) Coating agent preparation:

[0044] According to the following components in parts...

Embodiment 2

[0066] Embodiment 2: A kind of manufacture method of anti-seepage coating cloth.

[0067] The impermeable coating cloth such as figure 1 As shown, it consists of protective layer A1, internal reinforcement layer 2, bonding layer A3, base fabric 4, bonding layer B5, and protective layer B6 from top to bottom, wherein protective layer A1 is coating agent A, and internal reinforcement layer 2 is coating Layer agent B, bonding layer A3 are crosslinking coating agent B, bonding layer B5 are crosslinking coating agent B, protective layer B6 coating agent A; Its manufacture comprises the following steps:

[0068] (1) High-strength and low-shrinkage polyester yarn is used as raw material, with a fineness of 1300D, and it is manufactured on a high-speed rapier loom with Panama weaving method. The weaving density is 18×18 / inch, and the grammage is 404g / m 2 High-strength polyester base fabric;

[0069] (2) Coating agent preparation:

[0070] According to the following components in pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com