Repeatable printing paper

A technology for printing paper and paper stock, applied in the field of printing materials, can solve the problems of limited application scope, low contrast and resolution, etc., and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

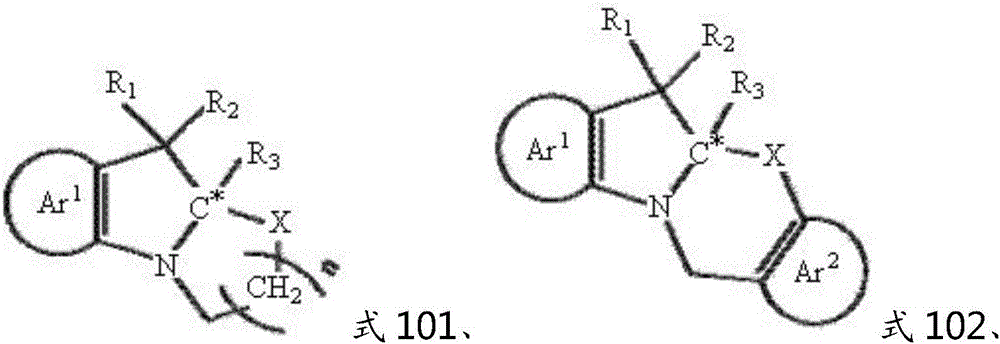

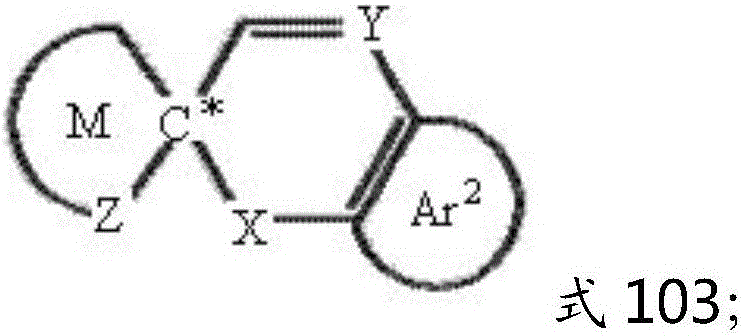

Method used

Image

Examples

preparation example Construction

[0065] In the present invention, the preparation method of described coating liquid preferably comprises the following steps:

[0066] The solvochromic spiro compound dye, organic solvent, water and sizing agent are mixed to obtain a coating solution.

[0067] In the present invention, the coated wet paper is calendered. The invention makes the paper have higher smoothness, glossiness, thickness and uniformity of the paper web through calendering. The present invention has no special limitation on the calendering method, and the calendering technical solution well known to those skilled in the art can be adopted. In the present invention, the required tightness is preferably achieved by pressing the upper and lower rollers during the calendering process, and the paper surface can be modified to a certain extent.

[0068] After the calendering is completed, the present invention preferably rolls the calendered paper, that is, rolls the paper web into a paper roll with a certa...

Embodiment 1

[0073] preparing the pulp to obtain a prepared paper stock; forming, pressing, coating and calendering the prepared paper stock in sequence to obtain reprintable printing paper;

[0074] The coating solution used in the coating includes 0.05g (E)-4-(2-(9,9-dimethyl-7-nitro-2,3,9,9a-tetrahydrooxazoline[3 ,2-a] indole-9a-)vinyl)-N,N-dimethylaniline dyestuff, 50g brand is the silane coupling agent of KH560, 4500g water and 500g styrene ester copolymer sizing agent;

[0075] The thickness of the coating layer was 1 μm.

[0076] The words written on the reprintable paper with a pen or brush dipped in clear water will disappear in 30 hours under the natural environment, and can be reused many times.

Embodiment 2

[0078] preparing the pulp to obtain a prepared paper stock; forming, pressing, coating and calendering the prepared paper stock in sequence to obtain reprintable printing paper;

[0079] The coating solution used in the coating includes 0.06g (E)-4-(2-(9,9-dimethyl-7-nitro-2,3,9,9a-tetrahydrooxazoline[3 ,2-a] indole-9a-)vinyl)-N,N-dimethylaniline dye, 100g brand is the silane coupling agent of KH560, 5000g water and 600g styrene ester copolymer sizing agent;

[0080] The thickness of the coating layer was 4 μm.

[0081] The reprintable paper is printed with an inkless waterjet printer, uses an acetic acid solution with a pH value of 4 as the printing color developer, and prints the font No. 5. Under the natural environment, it will disappear after 50 hours and can be reused many times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com