Ship elevator safety mechanism and mounting method thereof

A technology of safety mechanism and installation method, applied in the direction of vertical lifting of ship machinery, ship lifting device, building, etc., can solve problems such as catastrophic accidents, and achieve the effect of avoiding catastrophic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

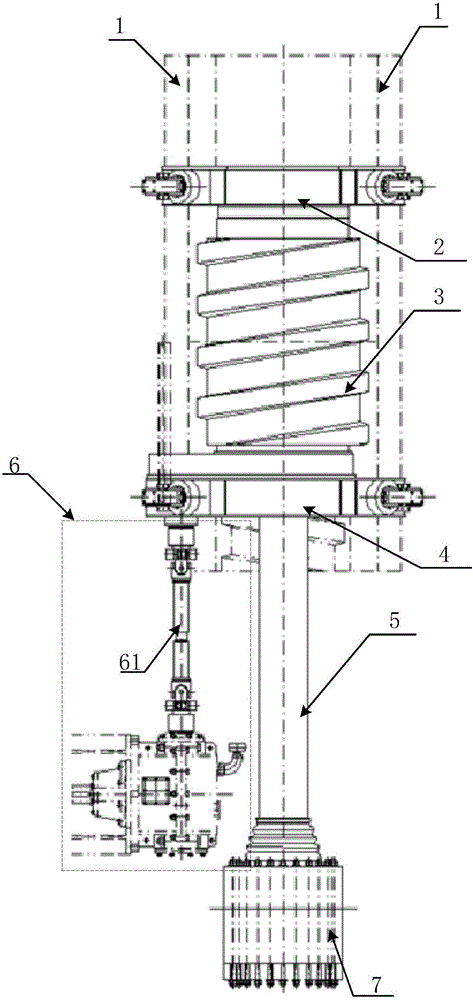

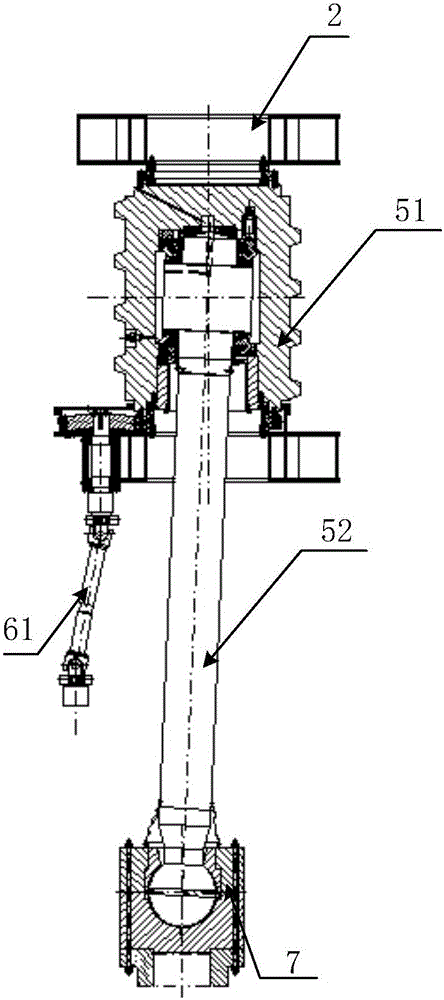

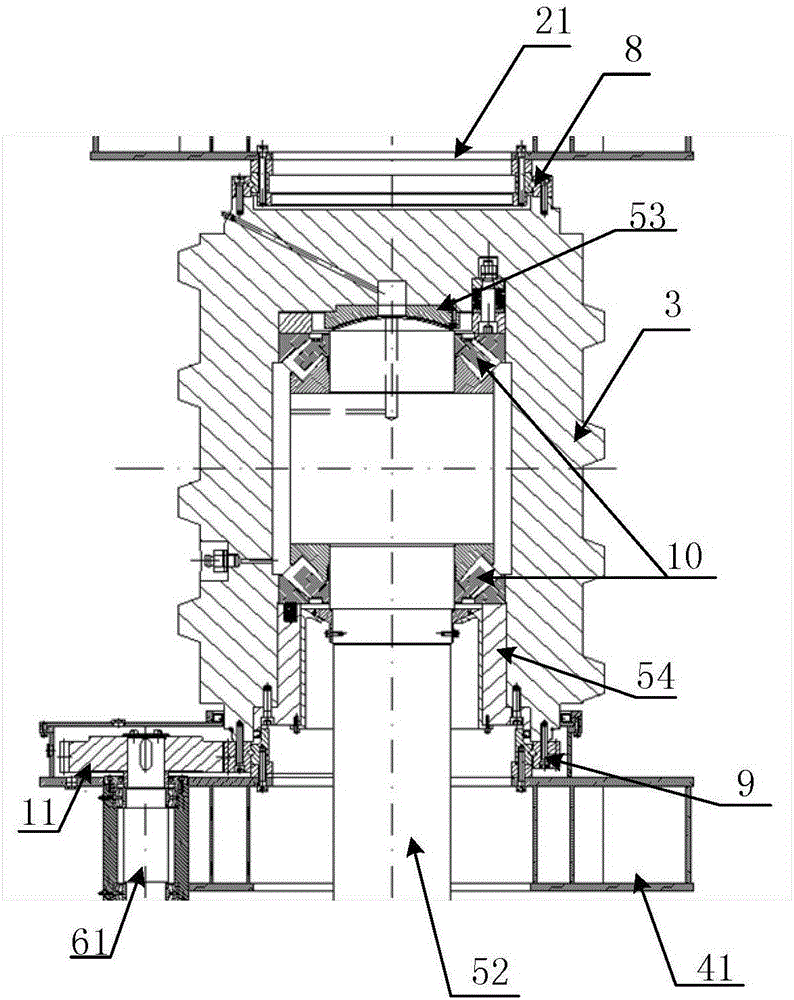

[0035] figure 1 It is a schematic diagram of the structural principle of the safety mechanism of the ship lift provided by Embodiment 1 of the present invention. Such as Figure 1 to Figure 3 As shown, the safety mechanism includes an upper guide frame assembly 2 , a lower guide frame assembly 4 , a safety screw 3 , a support rod assembly 5 and a transmission assembly 6 . The safety screw 3 is vertically arranged in the nut column 1, and the surface of the safety screw 3 is provided with an Archimedes helix, and the equivalent friction angle of the helical surface satisfies the self-locking condition. Keep a certain gap between them, the safety screw 3 is connected with the output shaft end of the reducer of the driving mechanism through the transmission assembly 6, the pitch of the safety screw 3 is an integer multiple of the pitch circle circumference of the pinion of the driving mechanism, through the transmission assembly 6 with an appropriate The transmission ratio guar...

Embodiment 2

[0044] Embodiment 2 is the installation method of the safety mechanism of the ship lift in Embodiment 1, specifically, including the following steps:

[0045] (1) Connect the screw installation machine with the lower ball hinge through the transition flange and bolts, and use the locking sleeve to connect the lower ball hinge with the screw roller of the installation machine, so that the clamping plate of the locking sleeve is closely attached to the flat side of the support rod, Used to transmit torque (according to calculations, the maximum torque that the clamp can provide is much greater than the torque required for screw rotation).

[0046] (2) Adjust the distance D=n*P+2*P between the tread surface of the roller of the spiral drum and the thread of the safety screw by rotating the safety screw, where n is an integer and P is the pitch.

[0047] (3) Install an expansion ring between the support rod and the inner hole at the lower end of the safety screw, and tighten the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com