Hydraulic system for torque test worktable and control method of hydraulic system

A technology of hydraulic system and workbench, which is applied in the directions of fluid pressure actuation system components, force/torque/work measuring instruments, fluid pressure actuation devices, etc., can solve the problem of not finding the hydraulic control system of the torque test workbench, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

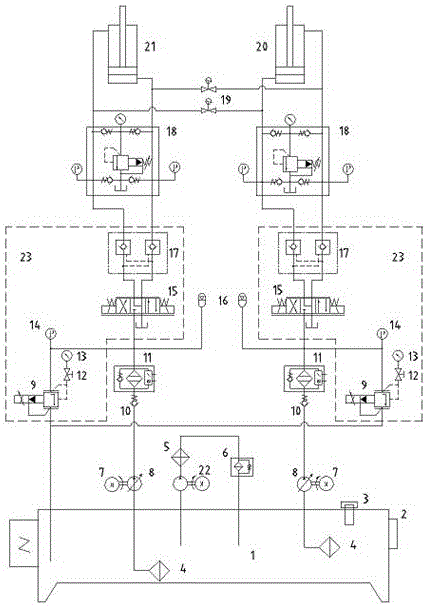

[0016] The present invention is a hydraulic system for a torque experiment workbench, which comprises a fuel tank 1 and two hydraulic oil circuits for controlling the movement of hydraulic cylinders;

Embodiment 2

[0018] Each hydraulic oil circuit includes oil suction filter 4, oil pump motor 7, variable displacement plunger pump 8, check valve 10, high pressure filter 11, pressure switch 12, pressure gauge 13, pressure sensor 14, accumulator 16, by Proportional overflow valve 9, proportional reversing valve 15, hydraulic control check valve 17, integrated valve group composed of oil circuit valve block 23, safety protection valve group 18, and a hydraulic cylinder; oil suction filter 4 is placed in oil tank 1, Oil suction filter 4, variable displacement plunger pump 8, check valve 10, high pressure filter 11, integrated valve group, safety protection valve group 18, and hydraulic cylinder are connected in series in sequence; variable displacement plunger pump 8 is connected to the output shaft of oil pump motor 7; The pressure switch 12, the pressure sensor 14, and the accumulator 16 are respectively connected to the pressure pipeline of the oil circuit valve block 23, and the pressure ...

Embodiment 3

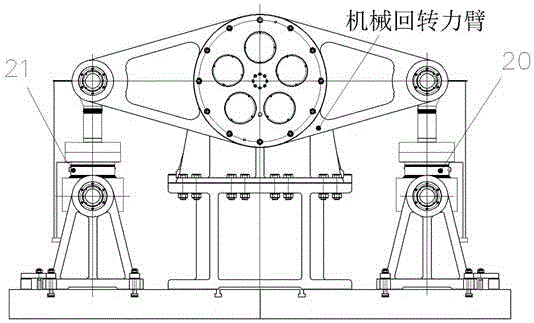

[0020] The rod chamber oil circuit of the tension hydraulic cylinder 20 is connected with the rodless chamber oil circuit of the thrust hydraulic cylinder 21; the rod chamber oil circuit of the tension hydraulic cylinder 20 is connected with the rod chamber oil circuit of the thrust hydraulic cylinder 21; The on and off of the road are all controlled by the electronically controlled one-way valve 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com