Method for measuring amylase content and amylopectin content of rice with half grains

A technology of amylose and amylopectin, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems affecting data repeatability, difficult accumulation of peak area, etc., achieve good application value, less sample amount, prevent The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

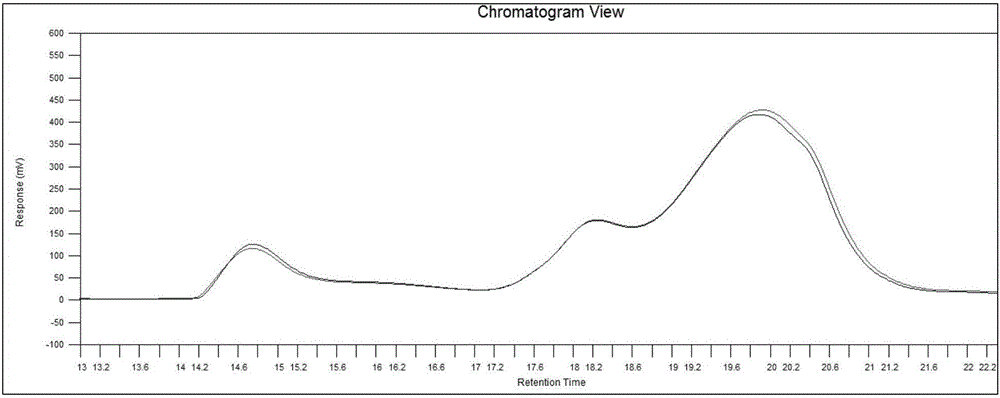

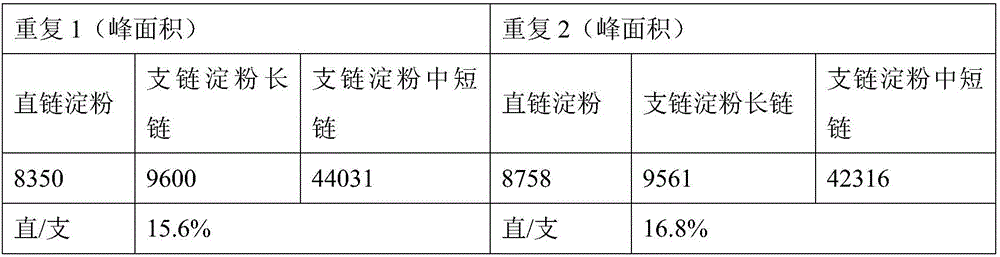

Embodiment 1

[0026] A method for measuring rice amylose and amylopectin content with half grain, the specific steps are:

[0027]Step 1: Pretreatment of rice flour: take single-grain rice (rice sample 9311) and manually shell it, scrape off the seed coat and aleurone layer of brown rice with a blade, then cut the polished rice into two and a half grains; take the rice without germ part Half a grain is ground into refined rice flour with a milling stick.

[0028] Step 2: Polish rice flour to remove fat and soluble sugar

[0029] Weigh 100mg of polished rice flour into a 10ml centrifuge tube, add 60ml of 100% chromatographically pure methanol, place in a boiling water bath for 10 minutes, centrifuge at 12,000g for 5 minutes, and pour off the suspension. Repeat this step 3 times for the precipitate.

[0030] Step 3: gelatinized starch and separation of amylose and branched chains

[0031] Weigh 20mg of the precipitate into a 2ml centrifuge tube, add 0.4ml of 0.25mol / L NaOH solution, and ba...

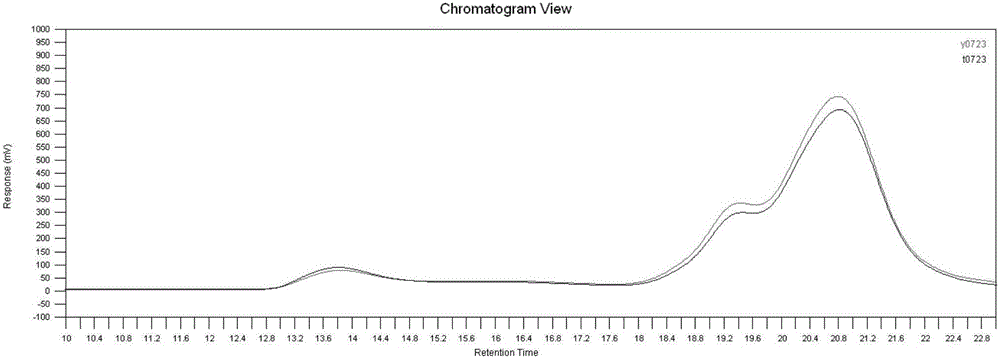

Embodiment 2

[0039] A method for measuring rice amylose and amylopectin content with half grain, comprising the steps:

[0040] Step 1: Pretreatment of rice flour: take single-grain paddy and shell it by hand, scrape off the seed coat and aleurone layer of brown rice with a blade, and then cut the polished rice into two halves; take the half grain without the germ part and grind it The sticks are ground into refined rice flour.

[0041] Step 2: Polish rice flour to remove fat and soluble sugar

[0042] Weigh 50mg of polished rice flour into a 10ml centrifuge tube, add 30ml of 100% chromatographically pure methanol, place in a boiling water bath for 10 minutes, centrifuge at 12,000g for 5 minutes, and pour off the suspension. Repeat this step 3 times for the precipitate.

[0043] Step 3: Weigh 10mg of the precipitate into a 2ml centrifuge tube, add 0.2ml of 0.25mol / L NaOH, and bake in an oven at 50°C for 2 hours. After mixing, add 80 μl of 0.5 mol / L sodium acetate (pH=4.0), then add 20 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com