Transformer substation inspection robot holder control method based on visual servo

A patrol inspection robot and visual servo technology, applied in the direction of non-electric variable control, attitude control, control/adjustment system, etc., can solve the problems of inspection collection image deviation, equipment area deviation, short movement distance, etc., to save labor Effects of labor resources, ensuring safe operation, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further defined below in conjunction with the accompanying drawings and specific embodiments.

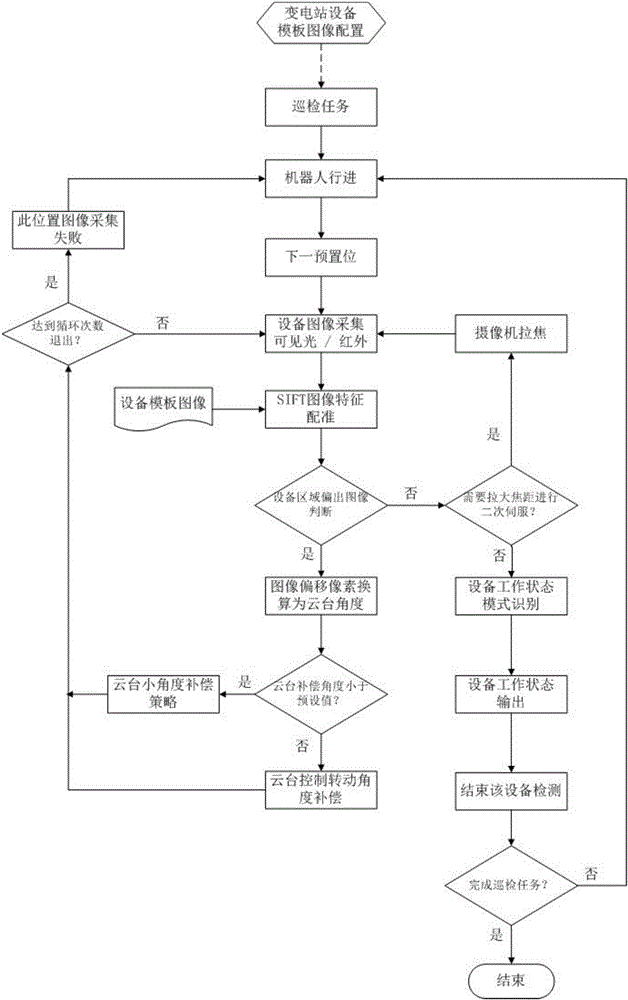

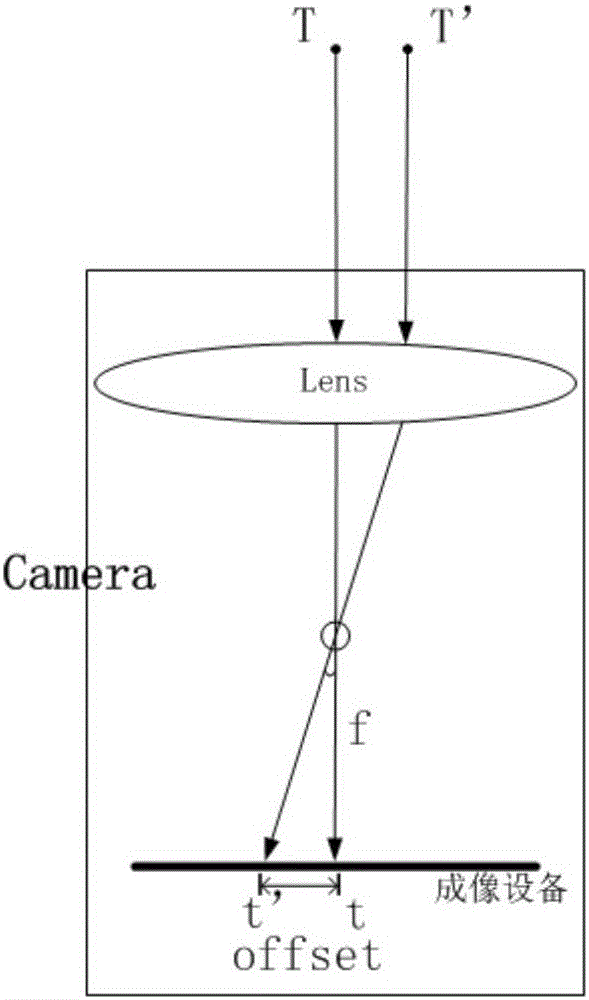

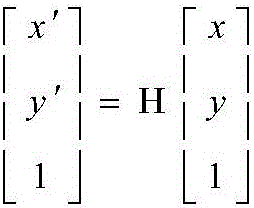

[0059] A visual servo-based control method for the substation inspection robot pan / tilt. First, the work of configuring the inspection robot includes saving the equipment images of each preset position of the substation taken by the robot into the template library, and the equipment area to be inspected It is presented in the center of the image with a suitable size, and the equipment area to be detected is manually marked in the template image. The equipment image in the template library corresponds to the equipment position of the substation one by one. When assigning inspection tasks to the robot, it is necessary to clearly point out the parameters (such as the angle of the pan / tilt, the focal length of the camera, etc.) of the template image taken at each preset parking space. Finally, adjust the attitude according to the acquisition method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com