Chip packaging structure and packaging method thereof

A chip packaging structure and packaging method technology, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as chip wafer warpage, and achieve the effects of low cost, simple process, and warpage reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] As a preferred embodiment, a packaging method of a chip packaging structure in the present invention includes the following steps, see Figure 10 :

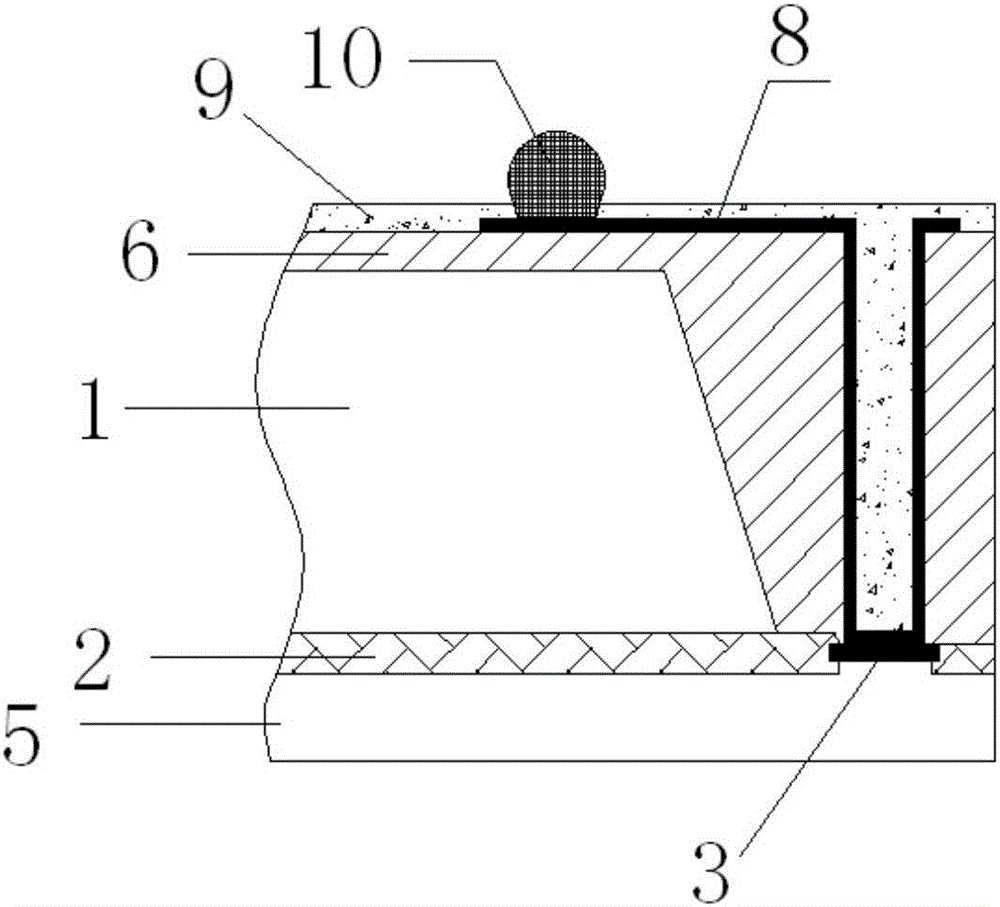

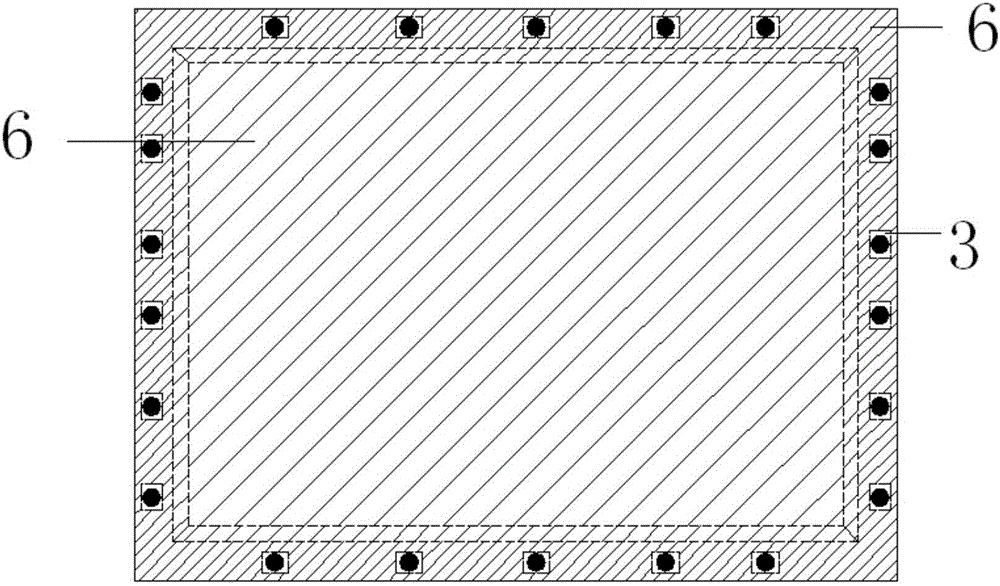

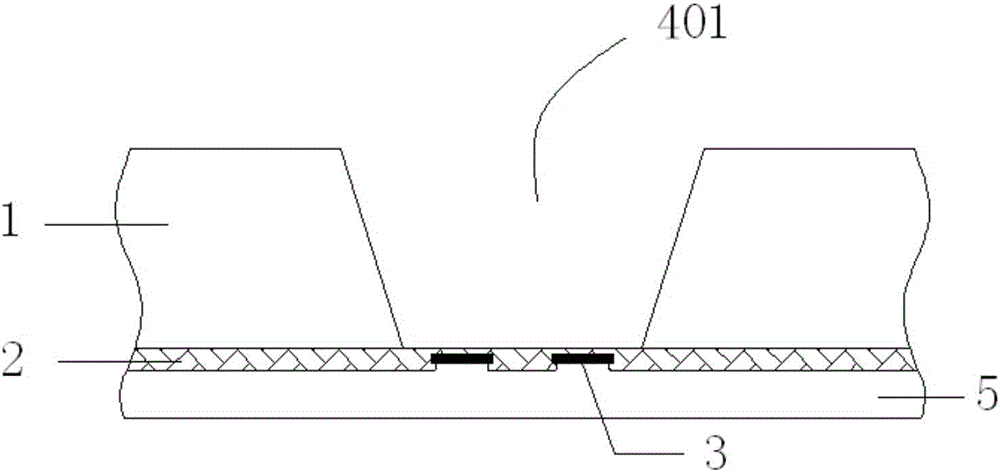

[0052] Step 1, see image 3 , take a wafer including a plurality of chip units 1, wherein the front of the chip unit has a dielectric layer 2, the middle part of the chip unit is a component area, and there are several welding pads 3 in or on the dielectric layer around the chip unit;

[0053] A pre-opening 401 is formed at a position between adjacent chip units on the back of the wafer, and the pre-opening removes chip substrate material on the pad and exposes the dielectric layer on the back of the pad. The method of forming the pre-opening is dry etching, wet etching or cutting.

[0054] Optionally, before forming the pre-opening, the back of the wafer can be thinned to thin the package thickness of the chip.

[0055] Optionally, before forming the pre-opening, a (temporary) carrier is bonded or not bonded on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com