Hydrophilized cellulose acetate tow band, and absorbent material produced using same

A technology of cellulose acetate and hydrophilization, which is applied in chemical post-treatment of cellulose/protein artificial filaments, absorbent pads, fiber treatment, etc., can solve problems such as quality degradation and deterioration of working environment, and achieve improved water absorption characteristics, liquid Excellent retention and thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

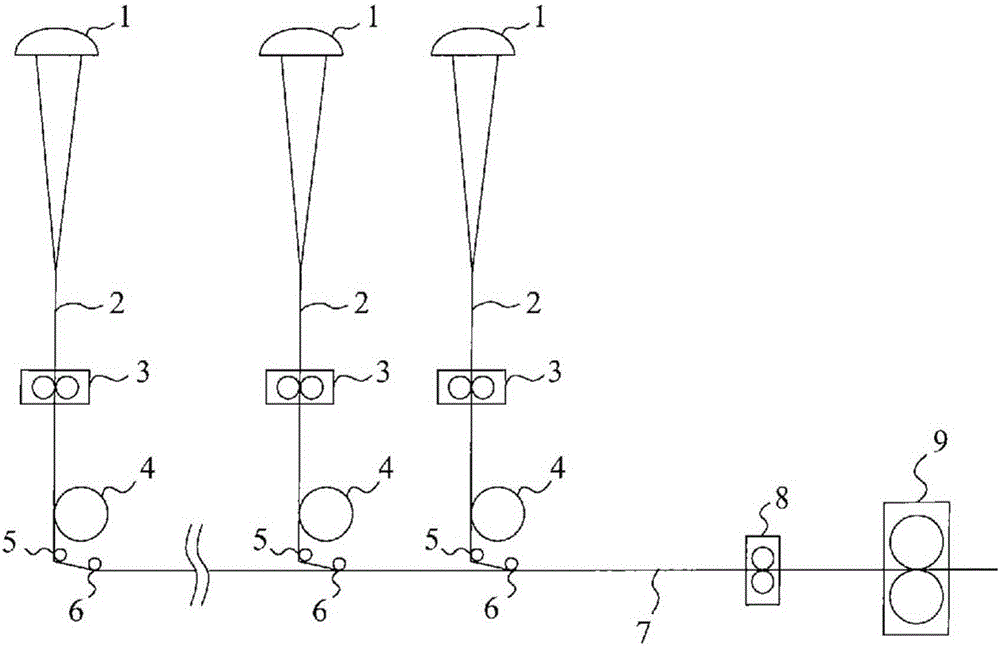

Method used

Image

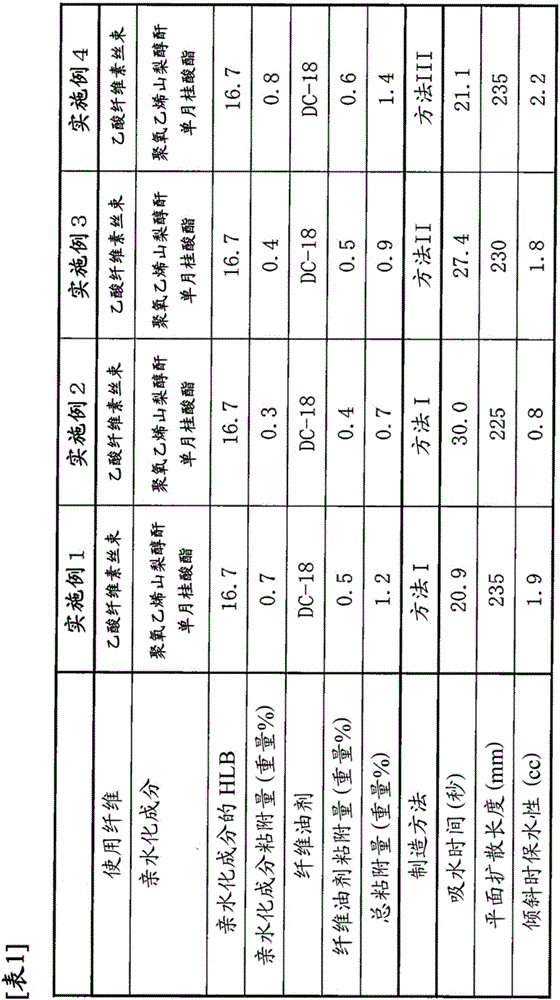

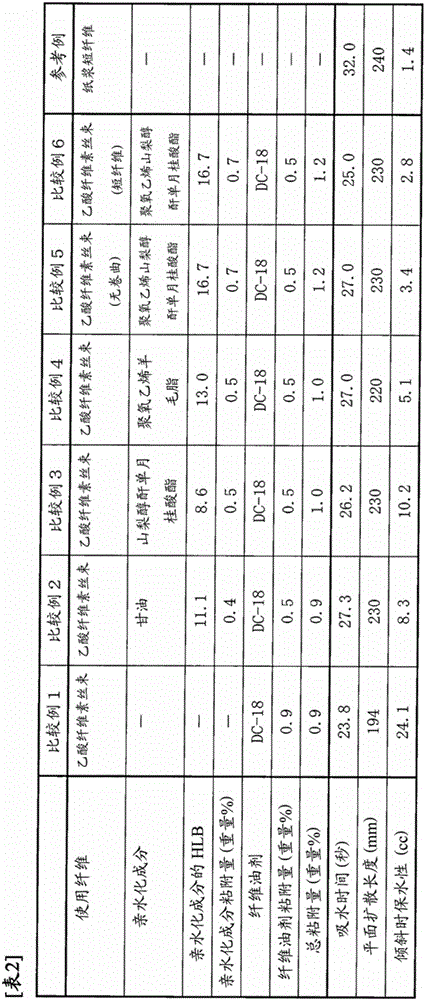

Examples

preparation example 1

[0102] Fiber oil (mineral oil, trade name "DC-18", manufactured by Matsumoto Yuyu Pharmaceutical Co., Ltd.) was adjusted to 35°C, and water (dilution water) adjusted to 35°C was added thereto and stirred to prepare an emulsion A fiber oil emulsion with a concentration of 40% by weight.

[0103] In addition, the phase transition point of the above-mentioned fiber oil is 50% by weight, and the dilution rate at the phase transition point is 0.13 kg / min per 1 kg of the fiber oil. The average particle size of the emulsion was 0.199 μm. In addition, the total light transmittance of 850 nm light measured at the emulsion concentration of 5% by weight of the obtained fiber oil emulsion was 34.8%.

preparation example 2

[0105] A hydrophilizing agent (polyoxyethylene sorbitan monolaurate, HLB value 16.7, manufactured by Matsumoto Yuyu Pharmaceutical Co., Ltd.) was dissolved in water to prepare a hydrophilizing agent aqueous solution having a concentration of 8.5% by weight.

preparation example 3

[0107] 100 parts by weight of the aqueous hydrophilizing agent solution obtained in Preparation Example 2 was added to 30 parts by weight of the fiber oil agent emulsion obtained in Preparation Example 1 and mixed to prepare a fiber oil agent-hydrophilizing agent mixed liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com